Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 218

ENGINE DRIVEABILITY AND EMISSIONS

6E–113

7

Repair the open or short to ground circuit between the

ECM and MAP sensor

Was the problem solved?

—

Verify repair

Go to Step 11

8

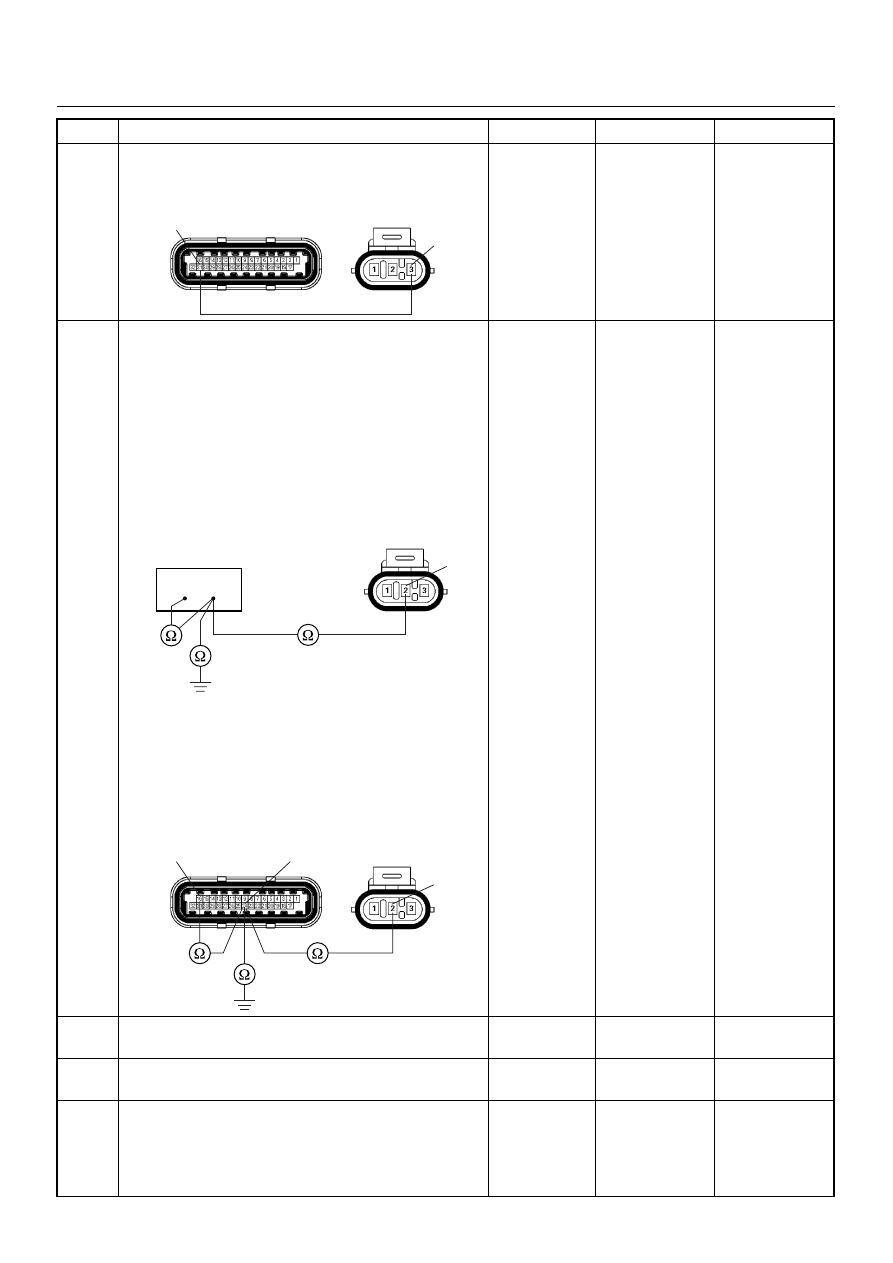

Using the DVM and check the MAP sensor signal

circuit.

Breaker box is available:

1. Ignition “Off”, engine “Off”.

2. Install the breaker box as type A. (ECM

disconnected) Ref. 6E-80.

3. Disconnect MAP sensor connector.

4. Check the circuit for open, short to sensor ground

or short to ground circuit.

Was the problem found?

Breaker box is not available:

1. Ignition “Off”, engine “Off”.

2. Disconnect the MAP sensor connector and ECM

connector.

3. Check the circuit for open, short to sensor ground

or short to ground circuit.

Was the problem found?

—

Repair faulty

harness and

verify repair

Go to Step 9

9

Substitute a known good MAP sensor and recheck.

Was the problem solved?

—

Go to Step 10

Go to Step 11

10

Replace the MAP sensor.

Is the action complete?

—

Verify repair

—

11

Is the ECM programmed with the latest software

release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved?

—

Verify repair

Go to Step 12

Step

Action

Value(s)

Yes

No

31

3

E85

E60(J1)

2

E85

16

24

16

24

2

E85

E60(J1)