Content .. 1685 1686 1687 1688 ..

Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 1687

6A-46 ENGINE MECHANICAL (C24SE, C22NE, 22LE, 20LE)

Installation

1.

Install the cylinder head gasket.

Mark "OBEN/TOP" on top and turn it towards timing side

of engine.

2.

Place cylinder head on cylinder block.

1

2

3

Installation

1.

Insert the hydraulic valve lifters (3), thrust pieces (2) and

cam followers (1) with MoS2 paste.

Note allocation.

2.

Apply a bead of Sealing Compound TB1207C to sealing

surface of cylinder head.

3.

Install the camshaft housing on cylinder head.

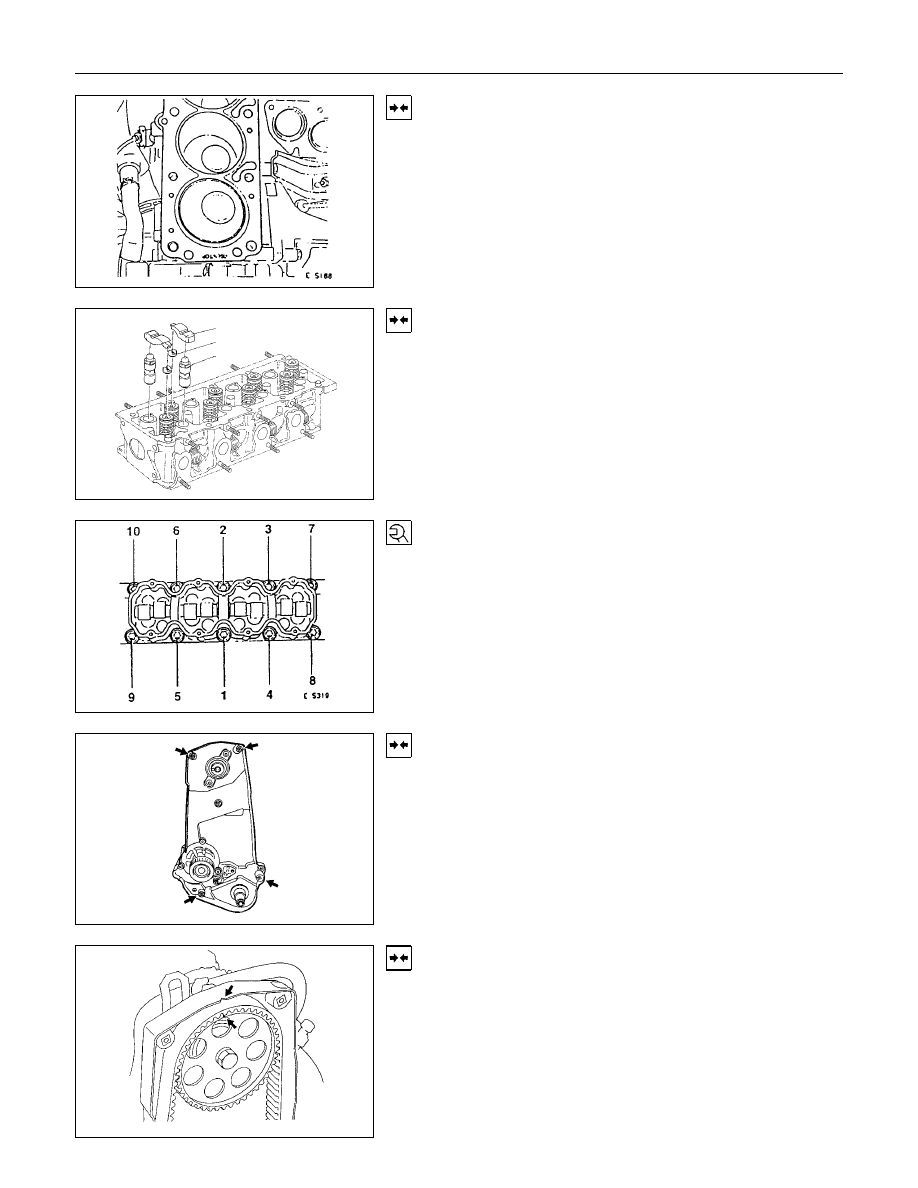

Torque-Angle Method

Cylinder head and camshaft housing with new cylinder head

bolts to cylinder block.

Cylinder head bolts in sequence shown.

Installation

1.

Install the rear toothed belt cover to camshaft housing.

2.

Install the camshaft pulley to camshaft.

3.

Install the camshaft housing cover to housing.

Installation

1.

Install the toothed belt on camshaft pulley.

See operation "Timing Adjust".

2.

Install the front toothed belt cover.