Content .. 1037 1038 1039 1040 ..

Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 1039

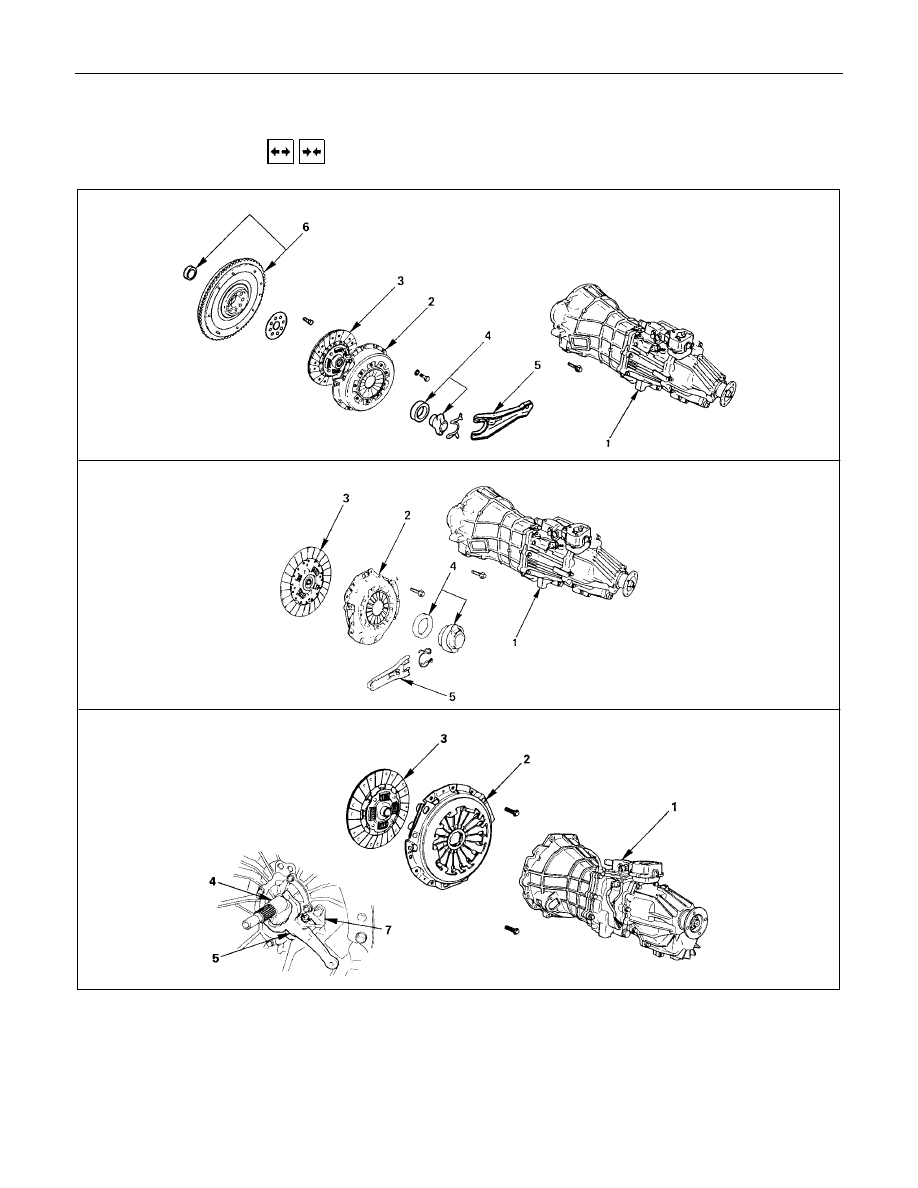

CLUTCH 7C-15

CLUTCH

REMOVAL AND INSTALLATION

HEC Engine Series

4J Engine Series

6VD1

Removal Steps

1. Transmission assembly

▲

2. Pressure Plate assembly

▲

3. Driven plate assembly

4. Release bearing

5. Shift fork

6. Flywheel assembly and cran bearing

(HEC Engine Series)

7. Fulcrum bridge (6VD1)

Installation Steps

To install, follow the removal steps in the

reverse order.