Content .. 999 1000 1001 1002 ..

Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 1001

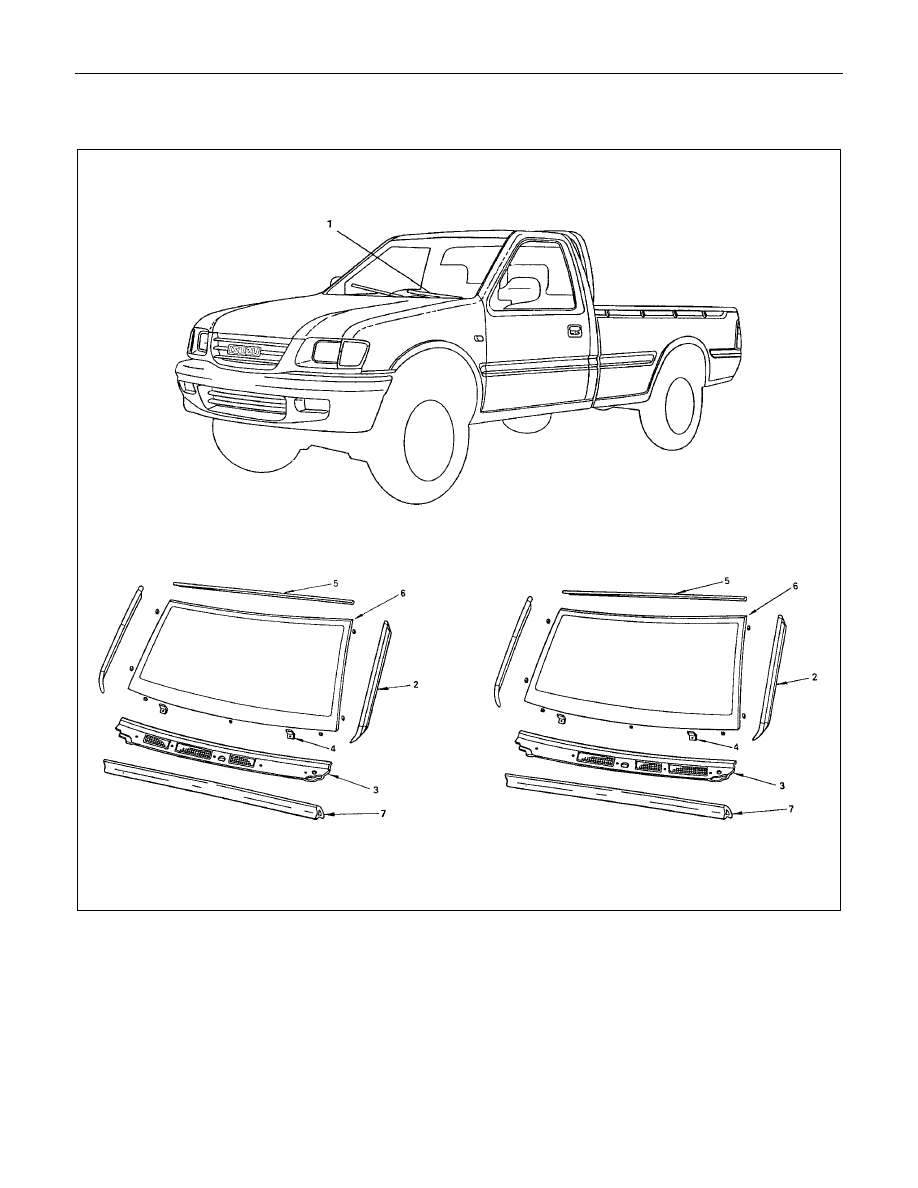

10-4 CAB

REMOVAL AND INSTALLATION

For RHD model

For LHD model

Removal Steps

1. Wiper arm assembly

2. Side moulding

3. Vent cowl cover

4. Windshield stopper

5. Upper moulding

V

6. Windshield glass

7. Engine hood rear seal

Installation Steps

V

7. Engine hood rear seal

V

6. Windshield glass

V

5. Upper moulding

V

4. Windshield stopper

3. Vent cowl cover

V

2. Side moulding

1. Wiper arm assembly