Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 78

4JA1-TC/4JH1-TC ENGINE DRIVEABILITY AND EMISSIONS

6E–307

Diagnostic Trouble Code (DTC) P1625 (Symptom Code B) (Flash Code 76) ECM

Main Relay Switched Off Too Late

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to On Board

Diagnostic

(OBD) System

Check

2

1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor As Stored By ECU” in

“F0: Diagnostic Trouble Codes”.

Is the DTC P1625 (Symptom Code B) stored as

“Present Failure”?

—

Go to Step 3

Refer to

Diagnostic Aids

and Go to Step

3

3

1. Using the Tech 2, ignition “On” and engine “Off”.

2. Select “F1: Clear DTC Information” in “F0:

Diagnostic Trouble Codes” with the Tech 2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F0: Read

DTC Infor As Stored By ECU” in the “F0:

Diagnostic Trouble Codes”.

Was the DTC P1625 (Symptom Code B) stored in this

ignition cycle?

—

Go to Step 4

Refer to

Diagnostic Aids

4

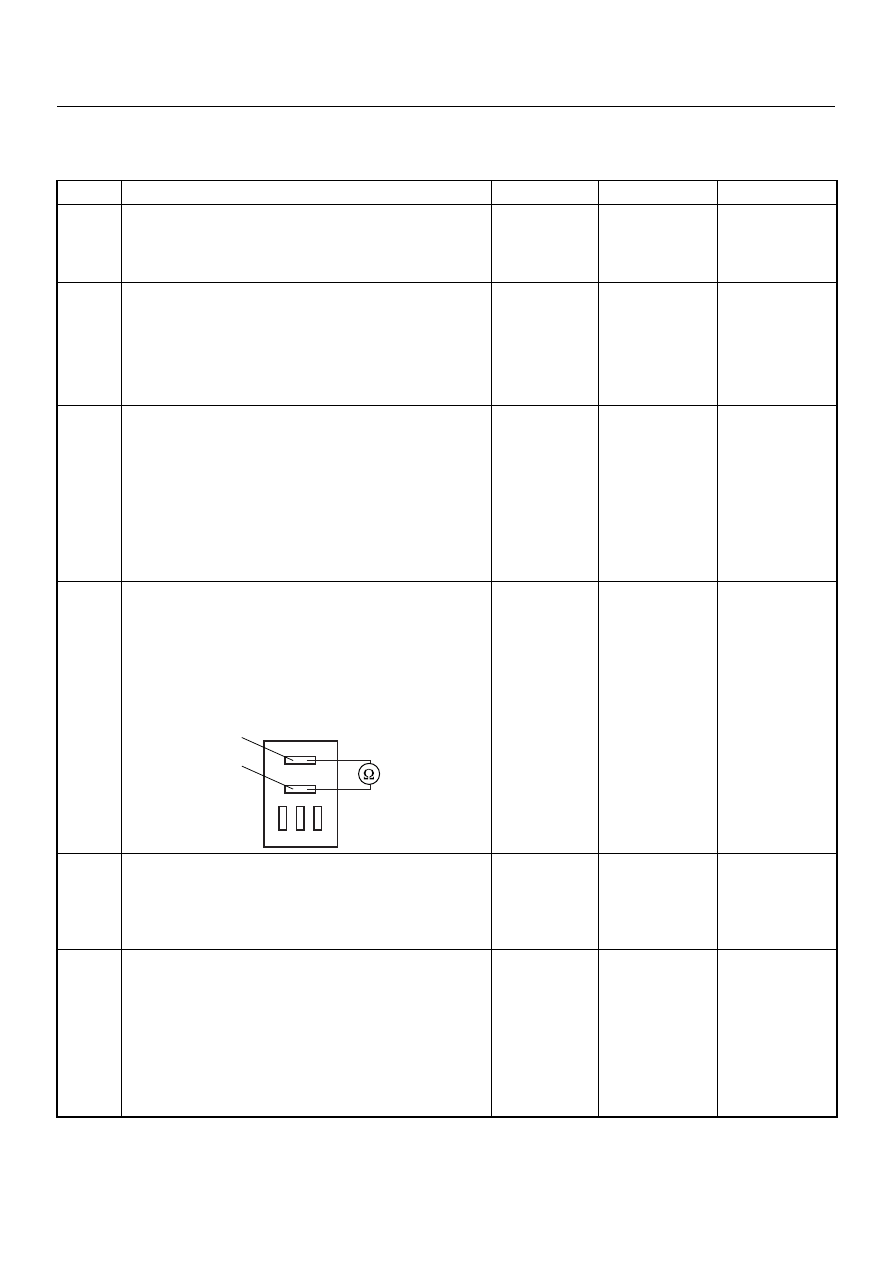

Using the DVM and check the ECM main relay.

1. Ignition “Off”, engine “Off”.

2. Remove the ECM main relay from the relay box.

3. Check the relay switch.

Was the DVM indicated specified value?

No continuitly

Go to Step 5

Replace ECM

main relay and

verify repair

5

Is the ECM programmed with the latest software

release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved?

—

Verify repair

Go to Step 6

6

Replace the ECM.

Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobiliser system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobiliser System-ECM replacement” for

the ECM/Immobiliser linking procedure.

—

Verify repair

—

1

2

ECM

Main Relay