Great Wall Florid. Manual - part 9

GWFLORID Maintenance Manual

34

Exhaust System Removal

Caution: Wait at least 30 minutes between the engine

being turned off and the actual removal of any component

of the exhaust system, as to avoid personnel injury due to

hot components.

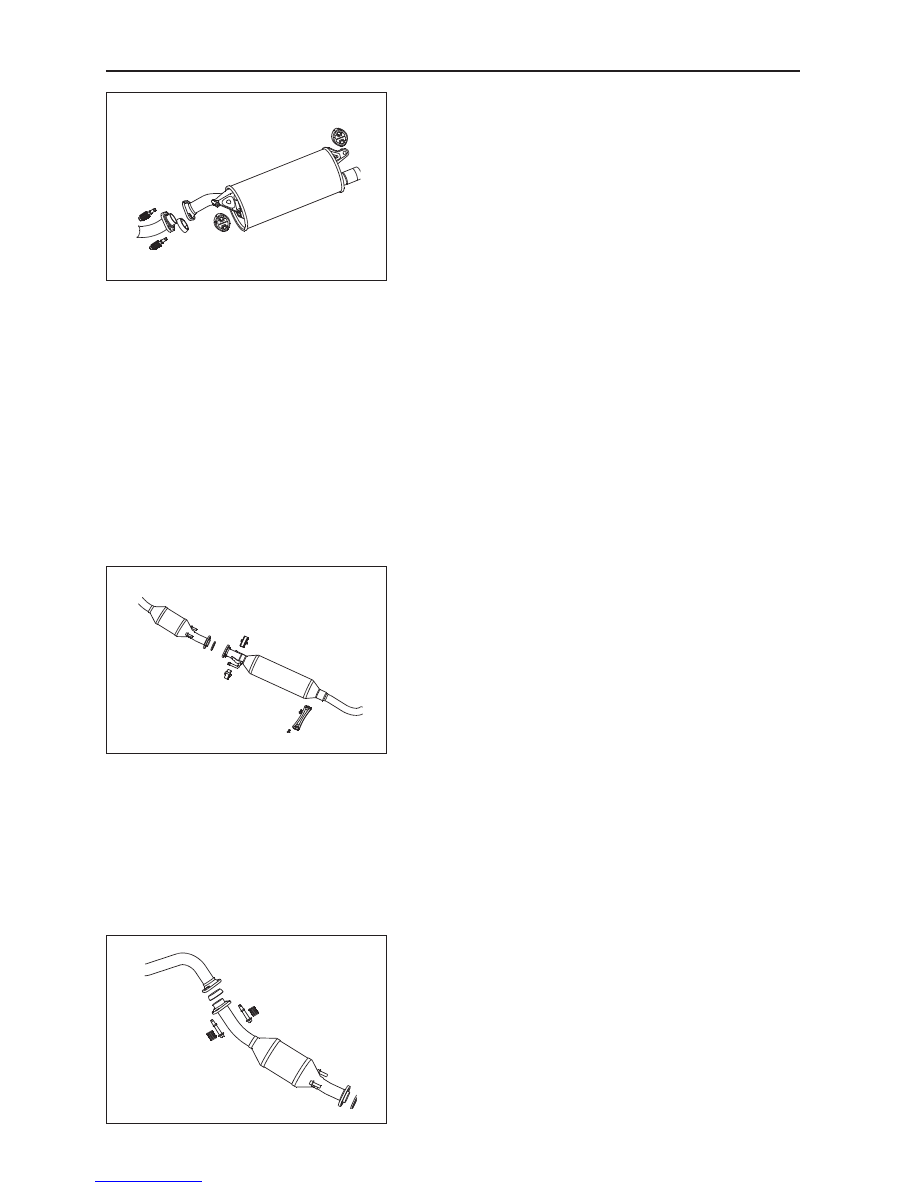

1. Main muffler assembly removal

(a) First use a No. 13 wrench (open), sleeve, or ratchet

spanner to remove the connecting spring bolt between

the front flange of the main muffler assembly and the

rear flange of the sub-muffler. Then take out the gasket

between the flanges.

(b) Remove the two rubber hangers on the main muffler.

(c) Take down the main muffler assembly.

Caution: The sealing ring between the front flange of

the main muffler assembly and the rear flange of the

sub-muffler is used only for sealing. If reused, it may

cause large deformations and result in a poor sealing

effect. Accordingly, it is suggested not to use a sealing

ring repeatedly. If necessary, only one repetition should

be allowed.

Warning: While performing this kind of maintenance

work, a person should be present to support the main

muffler to avoid injury in case the muffler falls.

2. Sub-muffler assembly removal

(a) Use a No. 14 wrench (open), sleeve, or ratchet wrench

to remove the connecting bolt between the front flange

of the sub-muffler assembly and the rear flange of the

catalyst assembly.

(b) Remove the support of the sub-muffler plate bracket.

(c) Remove the two two-hole rubber hangers between the

sub-muffler and the frame.

(d) Take down the sub-muffler assembly.

Caution: The sealing ring between the front flange of

the sub-muffler and the rear flange of the catalyst as-

sembly is used only for sealing. If reused, it may cause

large deformations and result in a poor sealing effect.

Accordingly, it is suggested not to use a sealing ring

repeatedly. If necessary, only one repetition should be

allowed.

Warning: While performing this kind of maintenance

work, a person should be present to support the sub-

muffler to avoid injury in case the muffler falls.

3. Rear catalytic assembly removal

(a) Remove the connecting spring bolt between the front

flange of the sub-muffler assembly and the rear flange

of the rear catalytic assembly. Then take out the sealing

ring between the flanges.

(b) Take off the rear catalytic assembly.