содержание .. 289 290 291 ..

Geely Emgrand X7. Manual part - 290

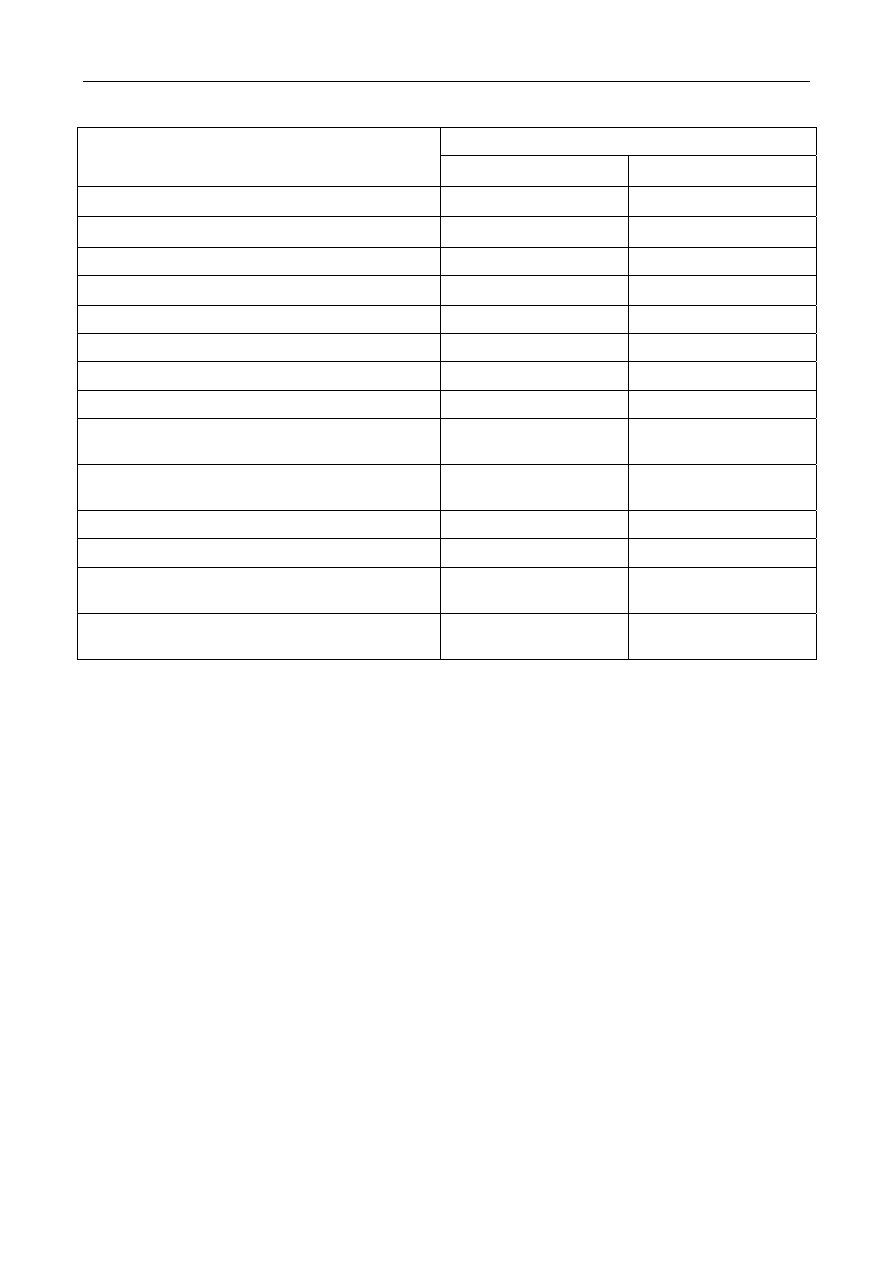

3.4.1.3 Size parameter specification

Specification

Dimensional parameter

Metric(mm) English

system(in×10-3)

Input shaft 3rd speed gear axial clearance

0.1~0.35

3.937 ~13.780

Input shaft 5th speed gear axial clearance

0.1~0.50

3.937~19.685

Input shaft 4th speed , 5th speed gear radial clearance

0.058

≦

2.146

≦

Input shaft 4th speed gear axial clearance

0.1~0.55 3.937~21.654

Input shaft run out

0.03

≦

1.181

≦

Distance synchronous ring back and gear end-face

0.8

≧

31.496

≧

Distance between gear bushing and shift fork

0.35

≦

13.780

≦

Min.diameter under the input shaft worn condition

33.985 and 30.985

1337.989 and 1219.879

Gear axial clearance of main shaft 1st speed and 2nd

speed

0.1~0.35 3.937~13.780

Gear radial runout of main shaft 1st speed and 2nd

speed

0.056

≦

2.205

≦

main bearing radial runout

0.03

≦

1.181

≦

Worn condition of main shaft:Min,diameter

33.985

1337.989

Distance from shift gear cove oil(sideward) seal end

-face to oil seal hole end-face

2.0~2.5 78.740~98.425

Distance from shift gear cove oil(upper side) seal end

-face to oil seal hole end-face

0~0.5 0~19.685

1159