Ford Fiesta (1989-1995). Instruction - part 11

inspecting carefully for any wear grooves,

pitting or scoring around the teeth.

21 Refit the thrustwasher with its curved side

facing outwards, followed by the Woodruff

key.

22 Lubricate the oil seal and the crankshaft

sprocket with engine oil, then position the

sprocket on the crankshaft with its thrust face

facing outwards.

23 Using the auxiliary drivebelt pulley and its

retaining bolt, draw the sprocket fully into

position on the crankshaft. Remove the

pulley.

24 Refit the timing belt as described in

Section 8.

10 Camshaft oil seal - renewal

3

1 Remove the camshaft sprocket as

described in the previous Section.

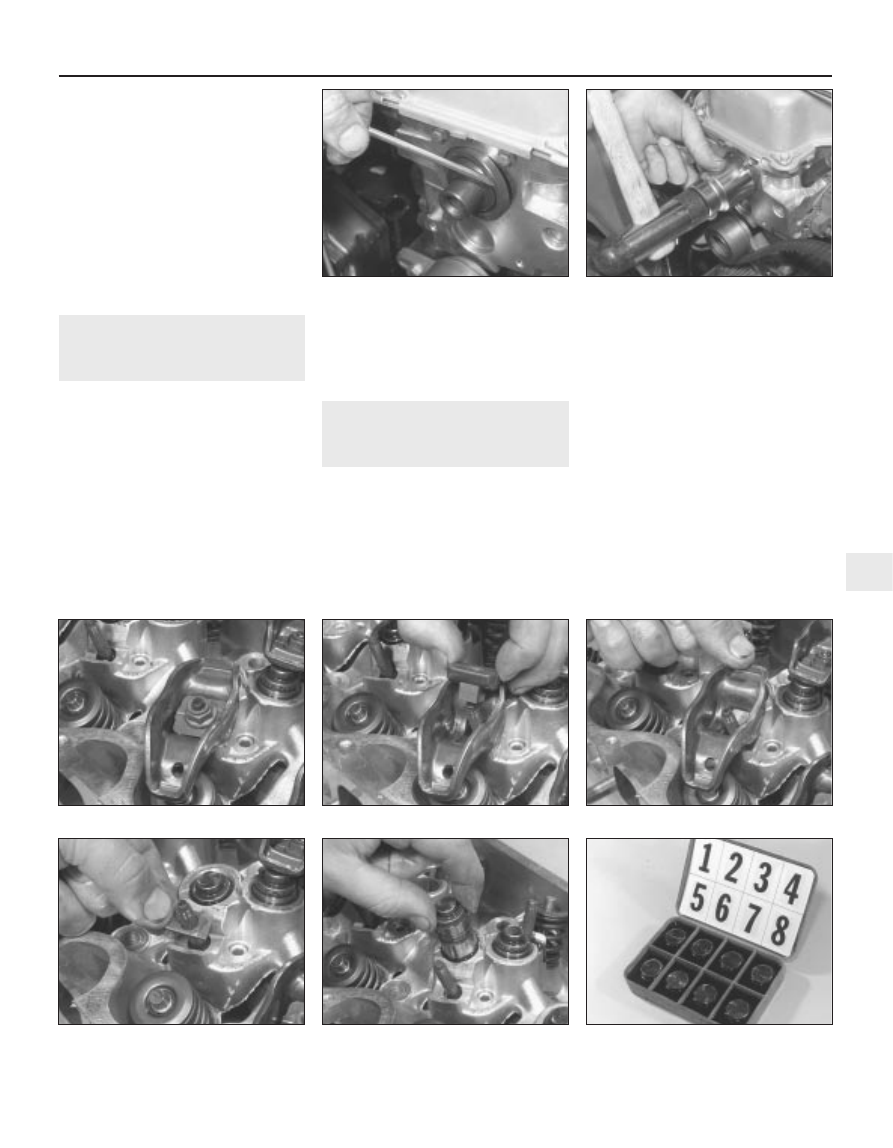

2 The oil seal is now accessible for removal.

Note its direction of fitting, then using a

suitable screwdriver or a tool with a hooked

end to lever and extract the seal from its

housing (but take care not to damage the

housing with the tool) (see illustration).

3 Check that the housing is clean before

fitting the new seal. Lubricate the lips of the

seal and the running faces of the camshaft

with clean engine oil. Carefully locate the seal

over the camshaft, and drive it squarely into

position using a suitable tube or a socket (see

illustration). An alternative method of fitting is

to draw it squarely into position using the old

sprocket bolt and a suitable distance piece.

4 With the seal fully inserted in its housing,

refit the camshaft sprocket as described in

the previous Section.

11 Camshaft, rocker arms and

tappets - removal, inspection

and refitting

3

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Refer to the appropriate earlier Sections in

this Chapter, and remove the timing belt

upper cover and the rocker cover.

3 On carburettor models, refer to Chapter 4A

and remove the fuel pump. On models

equipped with a distributor ignition system,

refer to Chapter 5B and remove the distributor.

On PTE engines, refer to Chapter 4D and

remove the camshaft position sensor.

4 On models equipped with distributorless

ignition system, detach, unbolt and remove

the ignition coil, its support bracket and the

interference capacitor from the end of the

cylinder head, as described in Chapter 5B.

5 Undo the retaining nuts and remove the

guides, rocker arms and spacer plates (see

illustrations). Keep the respective

components in their original order of fitting by

marking them with a piece of numbered tape,

or by using a suitable sub-divided box.

6 Withdraw the hydraulic tappets, again

keeping them in their original fitted sequence.

The tappets should be placed in an oil bath

while removed (see illustrations).

7 Unbolt and remove the lower cover beneath

CVH and PTE engine in-car repair procedures 2B•7

11.5a Undo the rocker arm retaining nut . . .

10.3 Using a socket to tap the camshaft

oil seal into place

11.6b Store tappets in clearly-marked

container filled with oil to prevent oil loss

11.6a Removing a hydraulic tappet

11.5c . . . followed by the rocker arm . . .

11.5b . . . withdraw the guide . . .

11.5d . . . and spacer plate

10.2 Camshaft front oil seal removal

2B

1595Ford Fiesta Remake