Ford Fiesta (1989-1995). Instruction - part 10

1

General information

How to use this Chapter

This Part of Chapter 2 is devoted to repair

procedures possible while the engine is still

installed in the vehicle, and includes only the

Specifications relevant to those procedures.

Similar information concerning the 1.3 litre

HCS engine, and the 1.6 and 1.8 litre Zetec

engines, will be found in Parts A and C of this

Chapter respectively. Since these procedures

are based on the assumption that the engine

is installed in the vehicle, if the engine has

been removed from the vehicle and mounted

on a stand, some of the preliminary

dismantling steps outlined will not apply.

Information concerning engine/transmission

removal and refitting, and engine overhaul, can

be found in Part D of this Chapter, which also

includes the Specifications relevant to those

procedures.

Engine description

The engine is a four-cylinder, in-line

overhead camshaft type, designated CVH

(Compound Valve angle, Hemispherical

combustion chamber) or PTE (Pent roof, high

Torque, low Emission). The PTE engine was

introduced for 1994 and, apart from

modifications to the cylinder head, camshaft

and intake system, is virtually identical to the

CVH engine it replaces. The engine is

mounted transversely at the front of the

vehicle together with the transmission to form

a combined power unit.

The crankshaft is supported in five split-

shell type main bearings within the cast-iron

crankcase. The connecting rod big-end

bearings are split-shell type, and the pistons

are attached by interference-fit gudgeon pins.

Each piston has two compression rings and

one oil control ring.

The cylinder head is of light alloy

construction, and supports the camshaft in five

bearings. Camshaft drive is by a toothed

composite rubber timing belt, which is driven by

a sprocket on the front end of the crankshaft.

The timing belt also drives the water pump,

which is mounted below the cylinder head.

Hydraulic cam followers (tappets) operate the

rocker arms and valves. The tappets are

operated by pressurised engine oil. When a

valve closes, the oil passes through a port in the

body of the cam follower, through four grooves

in the plunger and into the cylinder feed

chamber. From the chamber, the oil flows to a

ball-type non-return valve and into the pressure

chamber. The tension of the coil spring causes

the plunger to press against the valve, and so

eliminates any free play. As the cam lifts the

follower, the oil pressure in the pressure

chamber is increased, and the non-return valve

closes off the port feed chamber. This in turn

provides a rigid link between the cam follower,

the cylinder and the plunger. These then rise as

a unit to open the valve. The cam follower-to-

cylinder clearance allows the specified quantity

of oil to pass from the pressure chamber, oil only

being allowed past the cylinder bore when the

pressure is high during the moment of the valve

opening. When the valve closes, the escape of

oil will produce a small clearance, and no

pressure will exist in the pressure chamber. The

feed chamber oil then flows through the non-

return valve and into the pressure chamber, so

that the cam follower cylinder can be raised by

the pressure of the coil spring, eliminating free

play until the valve is operated again.

As wear occurs between the rocker arm

and the valve stem, the quantity of oil that

flows into the pressure chamber will be

slightly more than the quantity lost during the

expansion cycle of the cam follower.

Conversely, when the cam follower is

compressed by the expansion of the valve, a

slightly smaller quantity of oil will flow into the

pressure chamber than was lost.

A rotor-type oil pump is mounted on the

timing cover end of the engine, and is driven

by a gear on the front end of the crankshaft. A

full-flow type oil filter is fitted, and is mounted

on the side of the crankcase.

Repair operations possible with

the engine in the car

The following work can be carried out with

the engine in the car:

a)

Compression pressure - testing.

b)

Rocker cover - removal and refitting.

c)

Timing belt - removal, refitting and

adjustment.

d)

Camshaft oil seal - renewal.

e)

Camshaft - removal and refitting.

f)

Cylinder head - removal and refitting.

g)

Cylinder head and pistons - decarbonising.

h)

Crankshaft pulley - removal and refitting.

i)

Crankshaft oil seals - renewal.

j)

Oil filter renewal.

k)

Sump - removal and refitting.

l)

Flywheel - removal, inspection and refitting.

m) Mountings - removal and refitting.

Note: It is possible to remove the pistons and

connecting rods (after removing the cylinder

head and sump) without removing the engine.

However, this is not recommended. Work of

this nature is more easily and thoroughly

completed with the engine on the bench, as

described in Chapter 2D.

2

Compression test -

description and interpretation

2

Refer to Section 2 in Part A of this Chap-

ter.

3

Top Dead Centre (TDC) for

No 1 piston - locating

2

1 Top dead centre (TDC) is the highest point

of the cylinder that each piston reaches as the

crankshaft turns. Each piston reaches its TDC

position at the end of its compression stroke,

and then again at the end of its exhaust

stroke. For the purpose of engine timing, TDC

on the compression stroke for No 1 piston is

used. No 1 cylinder is at the timing belt end of

the engine. Proceed as follows.

2 Remove the upper timing belt cover as

described in Section 7.

3 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support”).

4 Undo the retaining bolts, and remove the

cover from the underside of the crankshaft

pulley.

5 Fit a spanner onto the crankshaft pulley bolt,

and turn the crankshaft in its normal direction

of rotation (clockwise, viewed from the pulley

end) to the point where the crankshaft pulley

timing notch is aligned with the TDC (0) timing

mark on the timing belt cover.

6 Although the crankshaft is now in top dead

centre alignment, with piston Nos 1 and 4 at

the top of their stroke, the No 1 piston may

not be on its compression stroke. To confirm

that it is, check that the timing pointer on the

camshaft sprocket is exactly aligned with the

TDC mark on the front face of the cylinder

head (see illustrations). If the pointer is not

aligned, turn the crankshaft pulley one further

CVH and PTE engine in-car repair procedures 2B•3

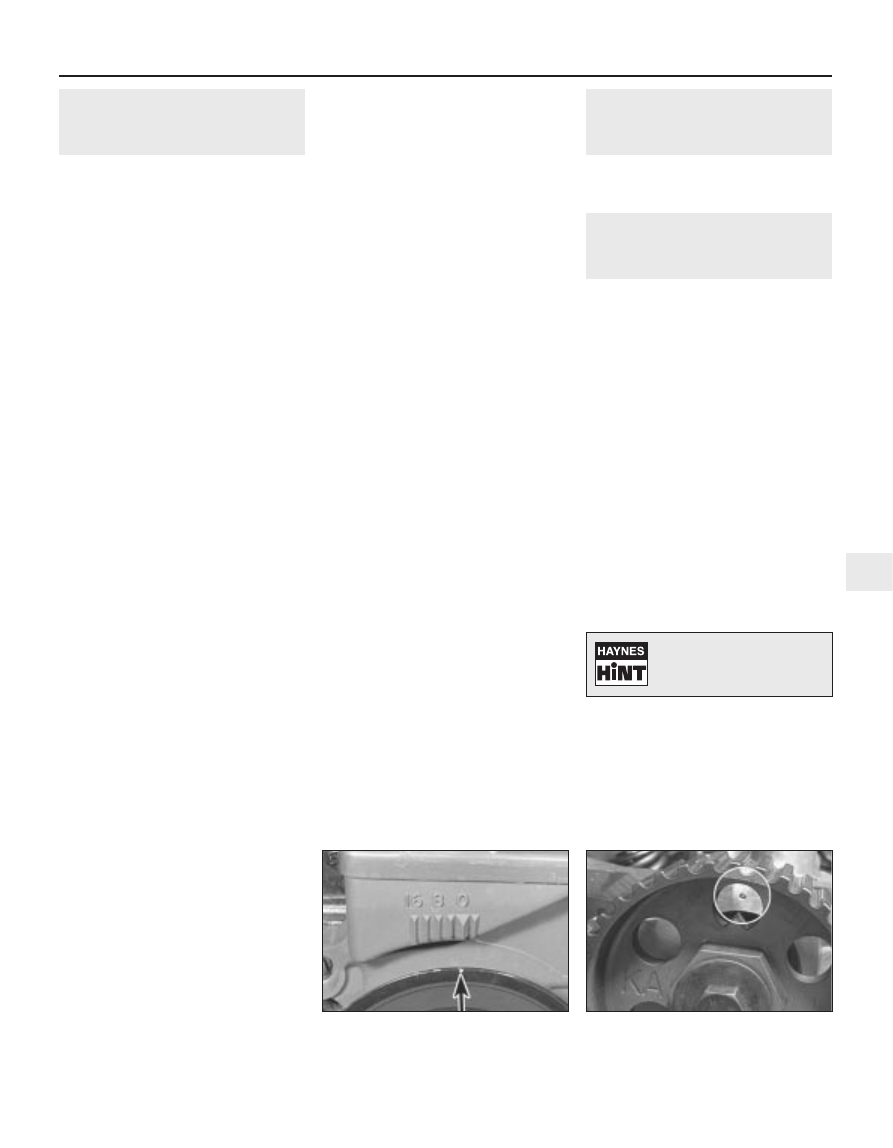

3.6b Camshaft sprocket timing mark

aligned with the TDC mark on the front

face of the cylinder head

3.6a Crankshaft pulley notch (arrowed)

aligned with the TDC (0) mark on the

timing belt cover

2B

1595Ford Fiesta Remake

Turning the engine will be

easier if the spark plugs are

removed first - see Chapter 1.