Bobcat S150. Manual - part 18

S150 Bobcat Loader

57

Operation & Maintenance Manual

OPERATOR CAB (CONT’D)

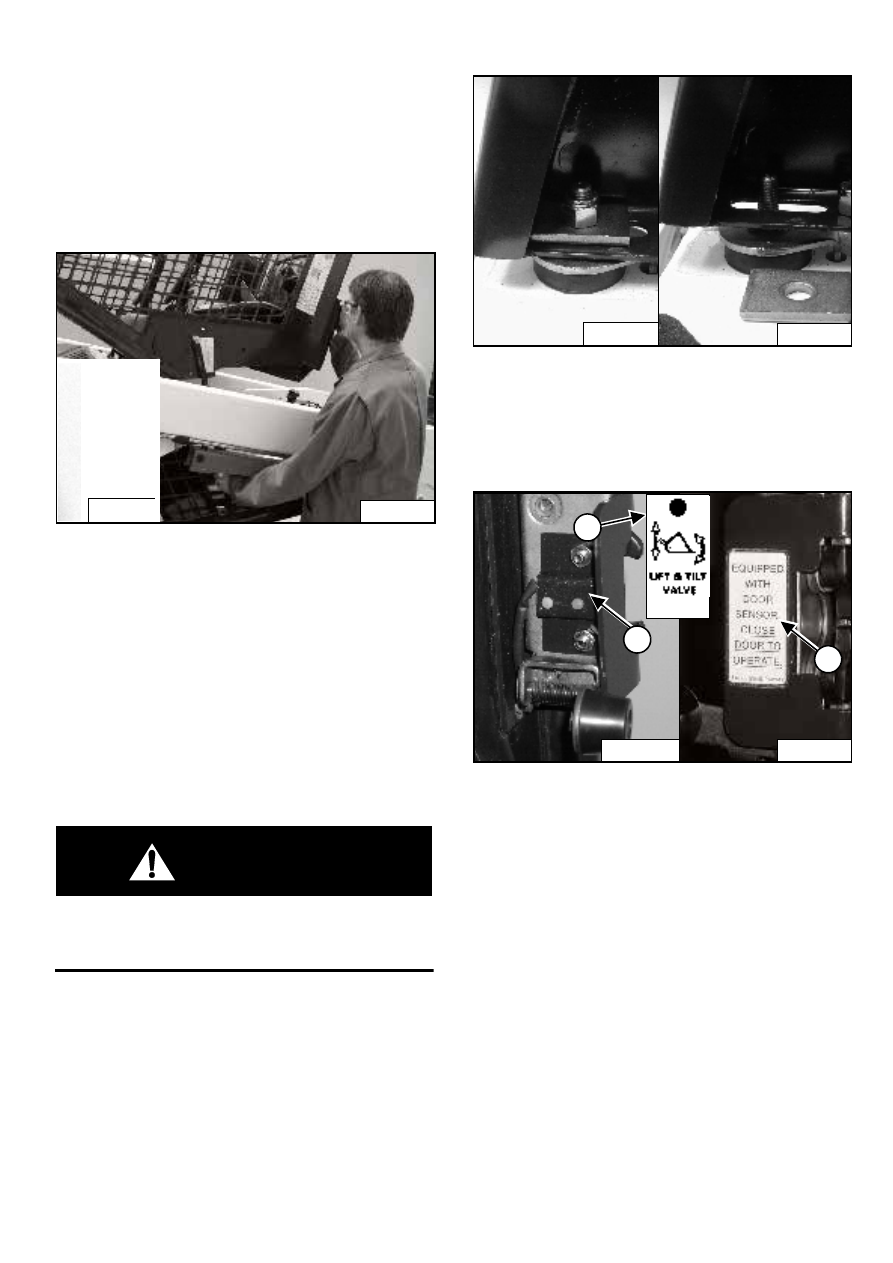

Lowering The Operator Cab

Always stop the engine before raising or lowering the cab.

NOTE: Make sure the seat bar is fully raised or

lowered when lowering the cab. Always use

the grab handles to lower the cab.

Figure 109

Pull down on the bottom of the operator cab until it stops

at the latching mechanism [Figure 109].

NOTE: The weight of the cab increases when

equipped with options and accessories such

cab door, heater, air conditioning, etc. In

these cases, the cab may need to be raised

slightly from the latch to be able to release the

latch.

Support the cab and release the latching mechanism

(Inset) [Figure 109]. Remove your hand from latching

mechanism when the cab is past the latch stop. Use both

hands to lower the cab all the way.

WARNING

PINCH POINT CAN CAUSE INJURY

Remove your hand from the latching mechanism

when the cab is past the latch stop.

W-2458-0103

Figure 110

Install the plates and nuts (both sides) [Figure 110].

Tighten the nuts to 54-68 Nm torque.

Cab Door Sensor

Figure 111

The cab door (option) has a sensor (1) [Figure 111]

installed which deactivates the lift and tilt valves when the

door is open.

A decal is located on the latch mechanism (2)

[Figure 111].

The LIFT & TILT VALVE light (3) [Figure 111] will be ON

when the door is closed and the PRESS TO OPERATE

LOADER Button is pressed.

P-45262

N-20120

P-31289

P-31288

P-34171

1

P-31202

3

2

B-15551j