Volvo 850. Manual - part 62

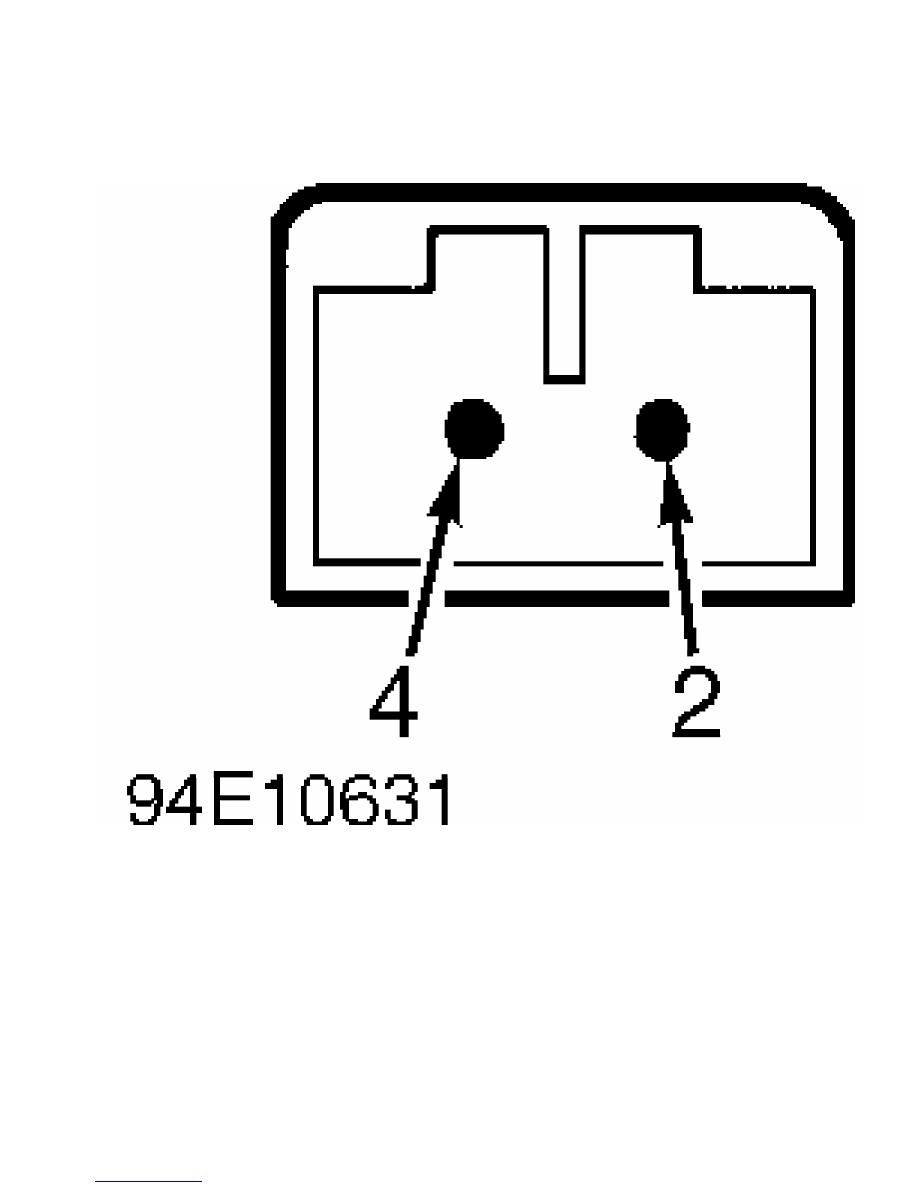

Fig. 9: Identifying Duct Temperature Sensor Terminals

Courtesy of Volvo Cars of North America.

DTC 1-3-2 & 1-3-4 DRIVER’S OR PASSENGER’S SIDE DUCT

TEMP. SENSOR CIRCUIT OPEN OR SHORTED TO POWER

1) If DTC 1-3-2 and 1-3-4 are both present, check for open

circuit in duct temperature sensor common ground (Brown wire). If DTC

1-3-2 and 1-3-4 are not both present, there is an open or short

circuit in wiring between ECC control module and duct temperature

sensor. Go to next step.

2) Ensure ignition is off. Connect test unit between ECC

control module and A/C system connector. Check ground circuit and

repair as necessary. See DTC 1-2-1, OUTSIDE TEMP. SENSOR CIRCUIT

SHORTED TO GROUND. If ground circuits are okay, go to next step.

3) Turn ignition on. Check driver’s side duct temperature

sensor wiring by checking voltage between test unit pins No. 56 and

47. Check passenger’s side duct temperature sensor wiring by checking

voltage between test unit pins No. 56 and 48. Voltage will vary with

duct temperature, but generally should be in 0-3 volt range.