Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 468

– If equipped, disconnect the connector -1- from the Oil Level

Thermal Sensor - G266- .

Caution

Risk of damaging the decoupling element.

♦ Do not bend the decoupling element more than 10°.

♦ Do not load the decoupling element.

♦ Do not damage the wire mesh on the decoupling element.

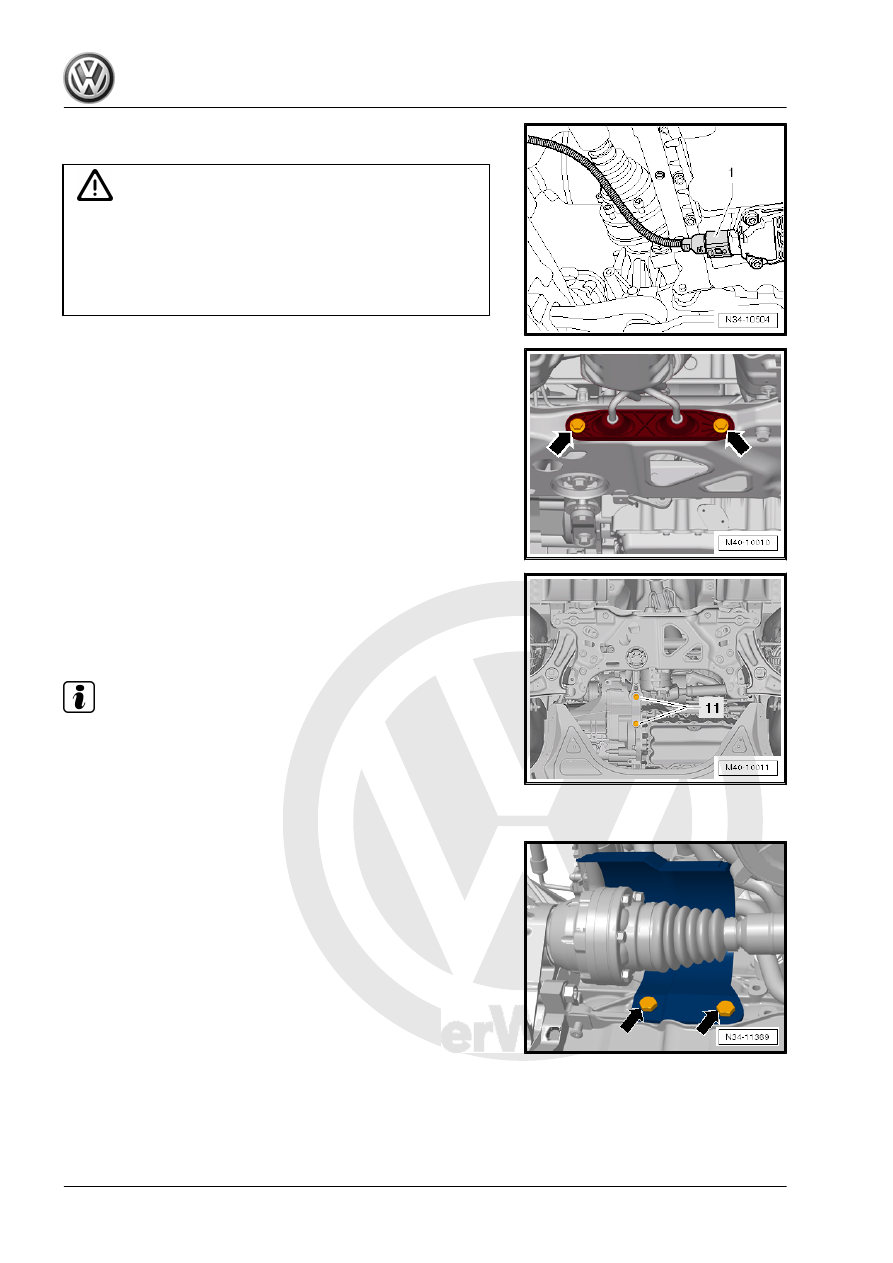

– Disconnect the exhaust system at the clamping sleeve and

remove the exhaust system bracket from the subframe

-arrows-. Refer to ⇒ Rep. Gr. 26 ; Exhaust Pipe/Muffler;

Overview - Muffler .

– Tie up the front exhaust pipe.

– Remove the bolts -11- and then remove the pendulum support

from the transmission.

– Secure the subframe before removing. Refer to ⇒ Suspen‐

sion, Wheels, Steering; Rep. Gr. 40 ; Subframe; Subframe,

Securing .

Note

If the subframe is not secured, a vehicle alignment must be per‐

formed later.

– Remove the subframe without the steering gear. Refer to ⇒

Suspension, Wheels, Steering; Rep. Gr. 40 ; Subframe; Sub‐

frame without Steering Gear, Removing and Installing .

– If equipped, remove the heat shield above the right driveshaft

-arrows-.

– Remove both driveshafts from the transmission. Refer to ⇒

Suspension, Wheels, Steering; Rep. Gr. 40 ; Driveshaft, Re‐

moving and Installing .