Volkswagen Touareg (2003 year). Manual - part 19

Note

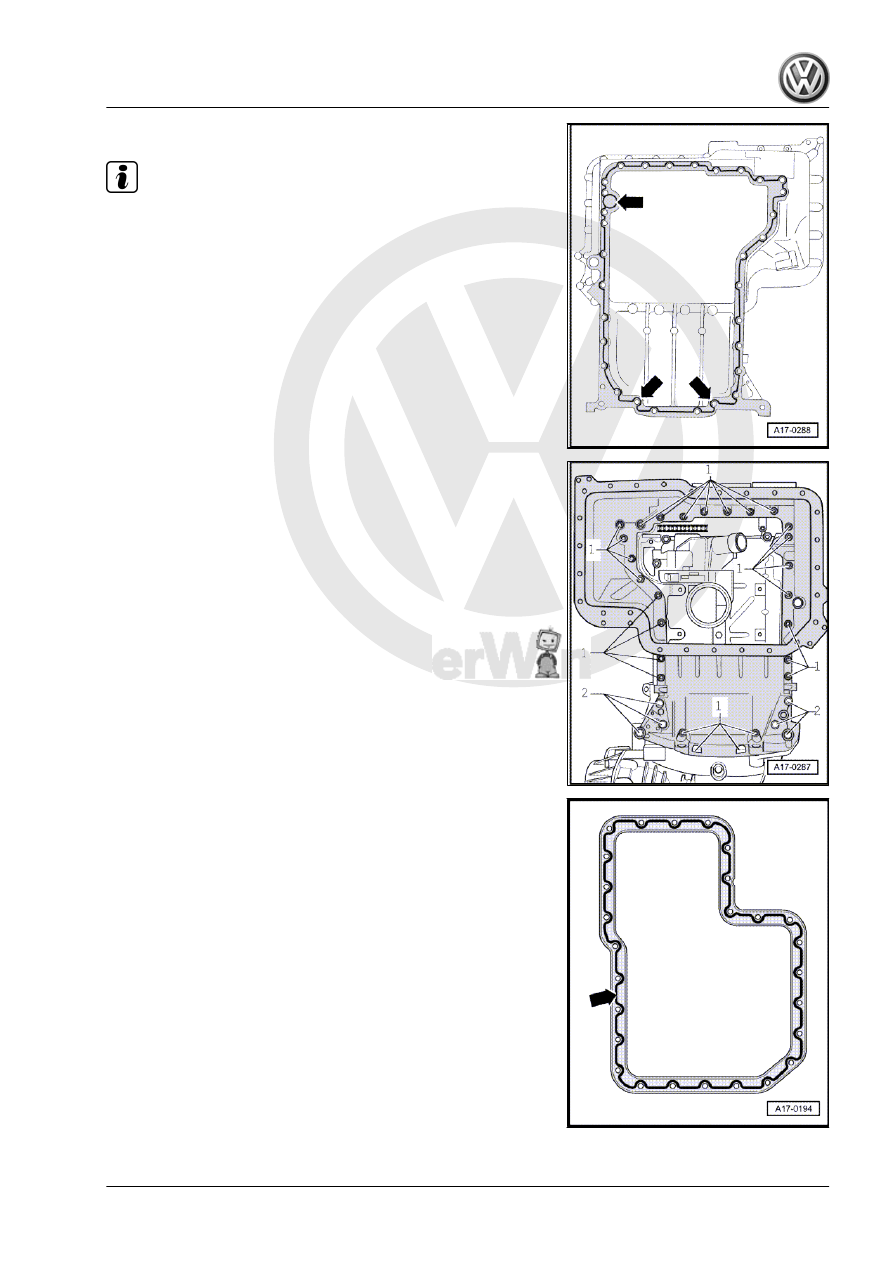

The sealant bead must not be thicker, otherwise excess sealing

compound will enter the oil sump and may block the oil suction

line strainer.

– Fit upper part of sump immediately and lightly tighten all sump

bolts „diagonally“.

– Then „diagonally“ tighten sump bolts -1- to 15 Nm and bolts

-2- to 22 Nm.

Now apply an approx. 1.5 mm bead of sealing compound

-arrow- onto the clean sealing flange of the lower part of the oil

sump as shown on illustration.

– Fit lower part of sump immediately and lightly tighten all sump

bolts „diagonally“.

– Then „diagonally“ tighten oil sump bolts to 10 Nm.

– Insert dipstick guide tube.

Touareg 2003 ➤

1. Removing and installing parts of lubrication system

73