Volkswagen Touareg (2003 year). Manual - part 14

Note

Valves must not be reworked. Only lapping-in is permitted.

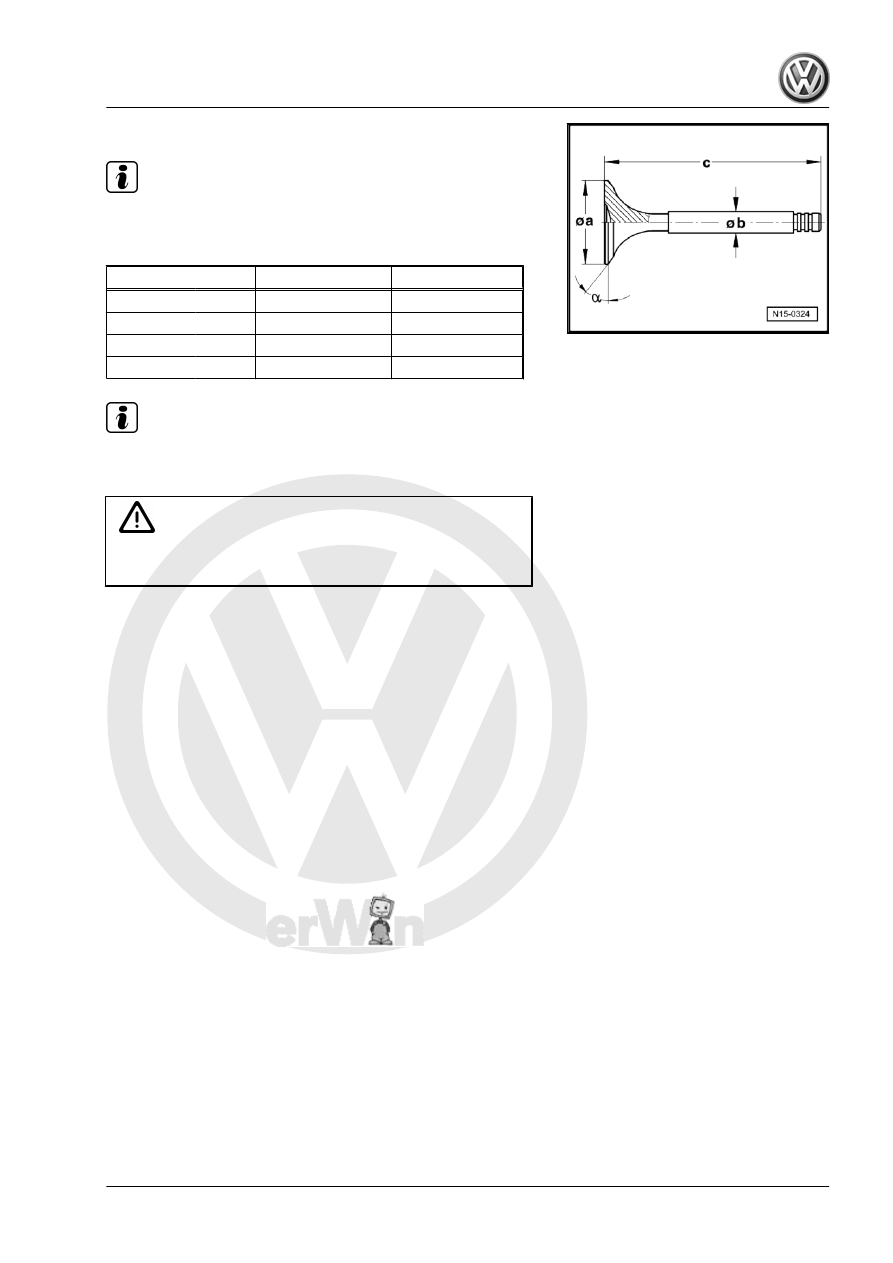

Valve dimensions

Dimension

Inlet valve

Exhaust valve

-∅ a-

mm

26.8...27.0

29.8...30.0

-∅ b-

mm

5.96...5.97

5.94...5.95

-c-

mm 104.84...105.34

103.64...104.14

-α-

∠°

45

45

Note

Worn sodium filled exhaust valves must not be disposed of with‐

out first preparing the valves.

WARNING

Wear eye protection and protective clothing to avoid eye inju‐

ries and chemical burns!

– They must be cut through in the centre of the stem with a

hacksaw. When doing this they must not come in contact with

water!

– When valves have been prepared as described, throw a max‐

imum of ten valves into a bucket filled with water and step

back!

– Due to the contact with water a sudden chemical reaction will

be initiated and the sodium fill will be burnt.

– After this treatment, the valves can be scrapped as normal

scrap.

2.1

Camshafts, checking axial clearance

Special tools and workshop equipment required

♦ Universal dial gauge bracket -VW 387-

♦ Dial gauge

Test procedure

Perform measurements with support elements and roller rocker

fingers removed.

Touareg 2003 ➤

2. Repairing valve gear

53