Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 190

1GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM–191

EM

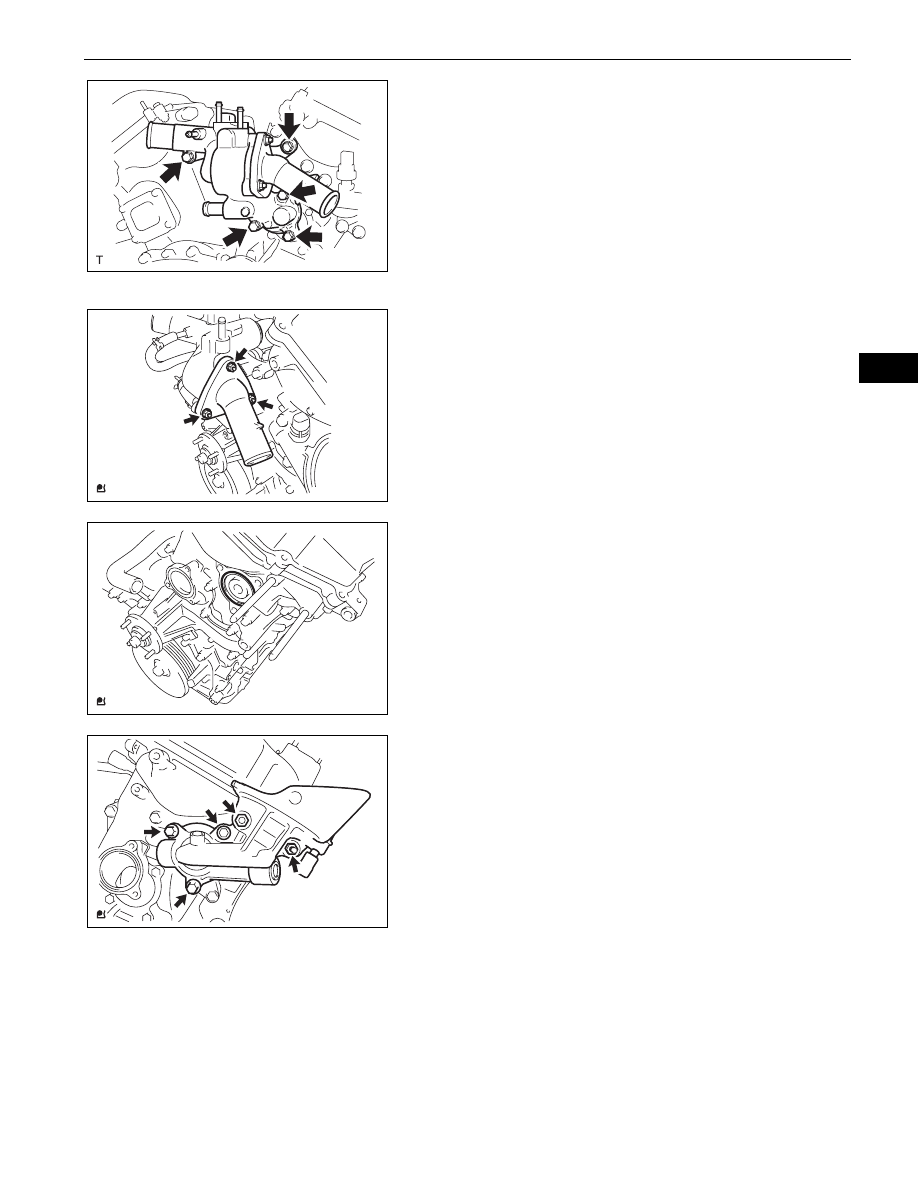

(c) Install the water inlet with the 5 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

55. INSTALL WATER BY-PASS HOSE

(a) Install the water by-pass hose with the 2 clamps.

56. INSTALL NO. 2 WATER BY-PASS HOSE

(a) Install the No. 2 water by-pass hose with the 2

clamps.

57. INSTALL NO. 3 WATER BY-PASS HOSE

(a) Install the No. 3 water by-pass hose with the 2

clamps.

58. INSTALL WITH THERMOSTAT WATER INLET SUB-

ASSEMBLY

(a) Install a new O-ring and the water inlet with

thermostat with the 3 nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

59. INSTALL OIL FILTER BRACKET SUB-ASSEMBLY

(a) Install the 2 stud bolts.

Torque: 10 N*m (102 kgf*cm, 7.4 ft.*lbf)

(b) Install a new gasket.

(c) Install the oil filter bracket with the 3 bolts and 2

nuts.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

A126462

A121042

A121046

A120414