Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 184

1GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM–167

EM

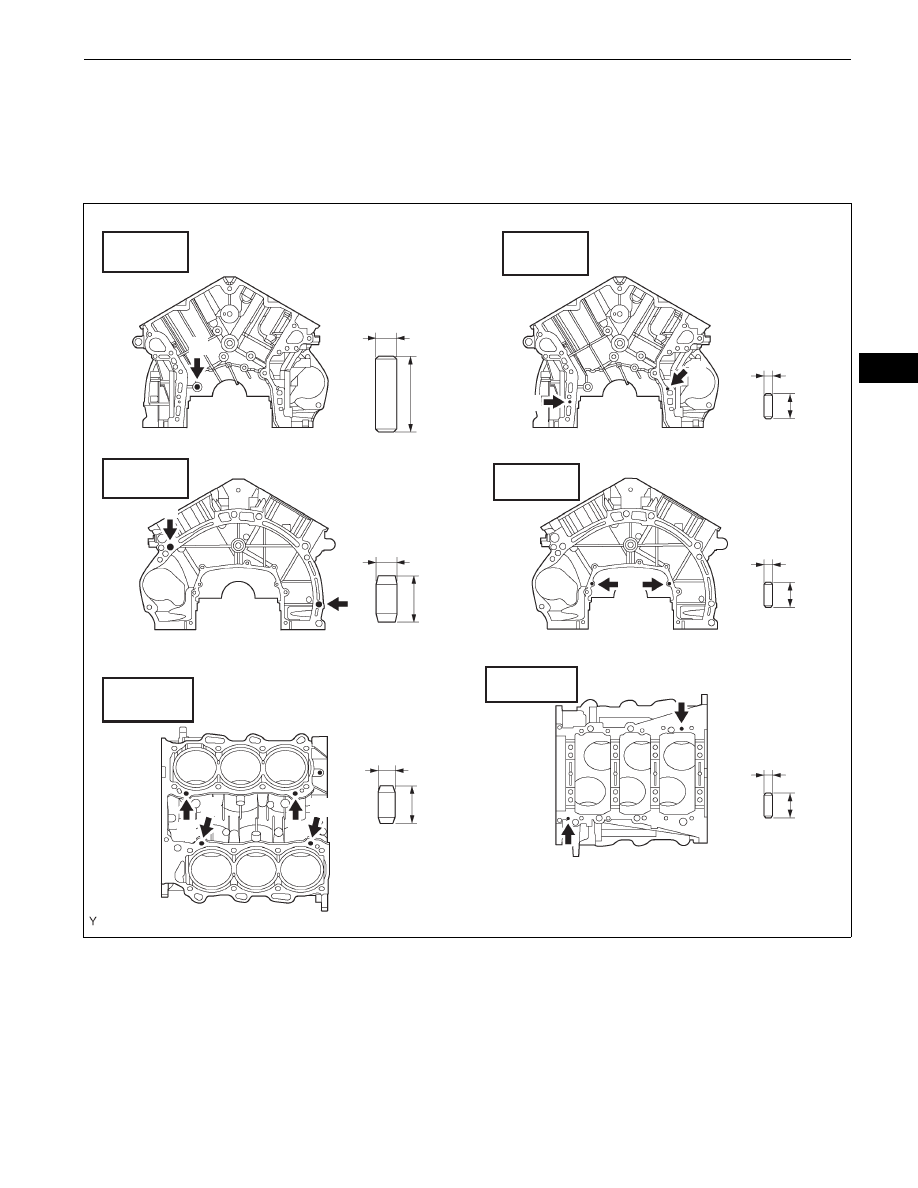

Pin B:

10.5 to 11.5 mm (0.413 to 0.453 in.)

Pin C:

8.5 to 9.5 mm (0.335 to 0.374 in.)

Pin D:

5.5 to 6.5 mm (0.217 to 0.256 in.)

4.

INSTALL TIGHT PLUG

(a) Apply adhesive around new tight plugs.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or the equivalent

(b) Using SST, install the tight plugs as shown in the

illustration.

SST

09550-60010 (09951-00350), 09950-70010

(09951-07150)

10 mm

10 mm

8mm

36mm

22 mm

18mm

12 mm

12 mm

12 mm

Protrusion Height: 22.5 to 23.5 mm

Protrusion Height: 5.5 to 6.5 mm

Protrusion Height: 5.5 to 6.5 mm

Protrusion Height: 5.5 to 6.5 mm

Protrusion Height: 10.5 to 11.5 mm

Protrusion Height:

8.5 to 9.5 mm

D

D

D

4 mm

4 mm

4 mm

C

C

C

C

B

B

A

Front Side

Rear Side

Upper Side

Front Side

Rear Side

Lower Side

D

D

A076062E04