Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 153

1GR-FE ENGINE MECHANICAL – CAMSHAFT

EM–45

EM

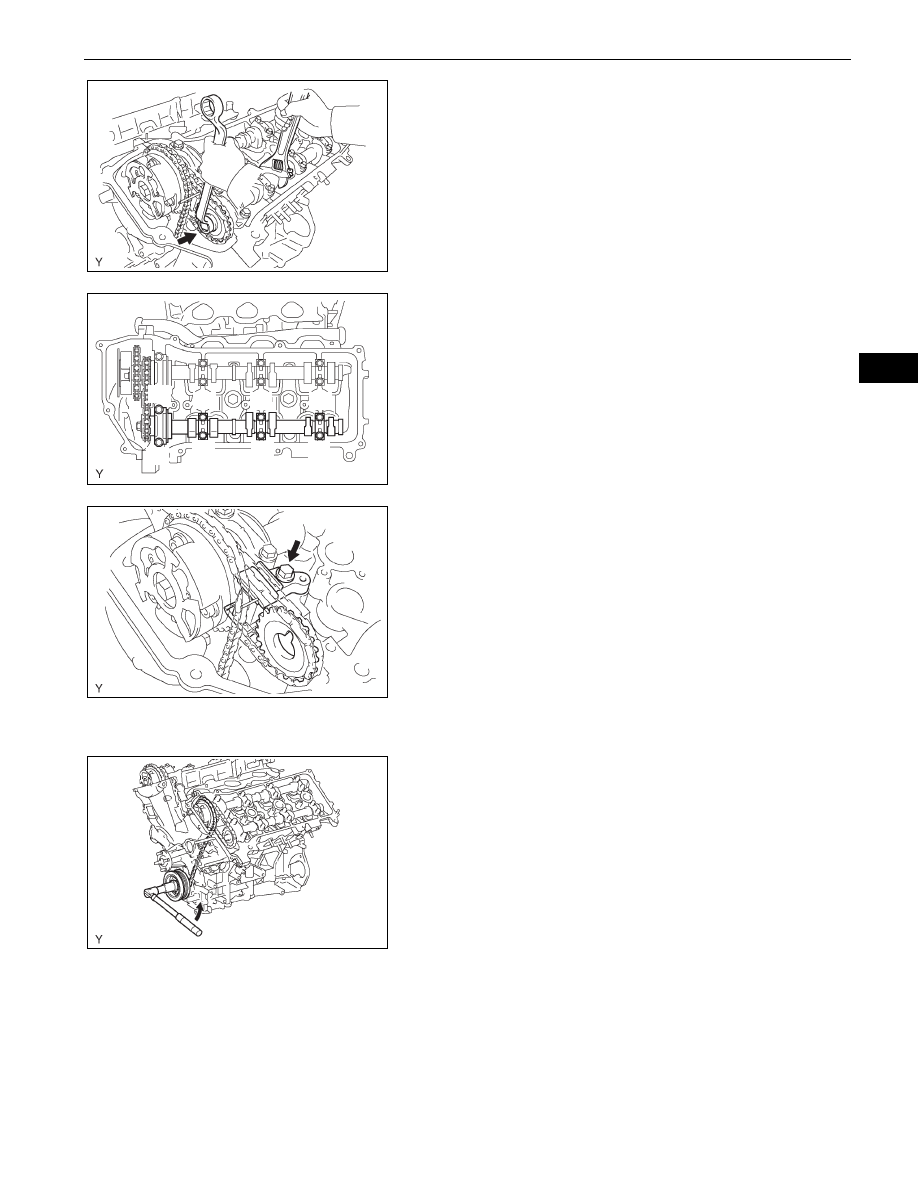

(b) Hold the hexagonal portion of the No. 4 camshaft

with a wrench, and remove the camshaft timing gear

set bolt.

NOTICE:

Be careful not to damage the cylinder head or

valve lifter with the wrench.

(c) Separate the camshaft timing gear from the No. 4

camshaft.

(d) Using several steps, uniformly loosen and remove

the 8 bearing cap bolts in the sequence shown in

the illustration.

(e) Remove the 4 bearing caps and No. 4 camshaft.

19. REMOVE NO. 3 CHAIN TENSIONER ASSEMBLY

(a) Remove the No. 3 chain tensioner bolt, then remove

the No. 3 chain tensioner and camshaft timing gear.

20. REMOVE NO. 3 CAMSHAFT SUB-ASSEMBLY

NOTICE:

Keep the camshaft level while it is being removed.

The camshaft thrust clearance is very small and

failing to keep it level could crack or damage the

cylinder head journal surface, which receives the

thrust force. This could subsequently lead the

camshaft to seize or break. Perform the following

steps to avoid such problems.

(a) Release the chain tension between the camshaft

timing gear (bank 2) and crankshaft timing gear by

turning the crankshaft pulley counterclockwise

slightly.

G036261E01

1

2

3

4

5

7

6

8

A076482E04

G036262E02

Slightly Turn

G036263E01