Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 100

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–355

ES

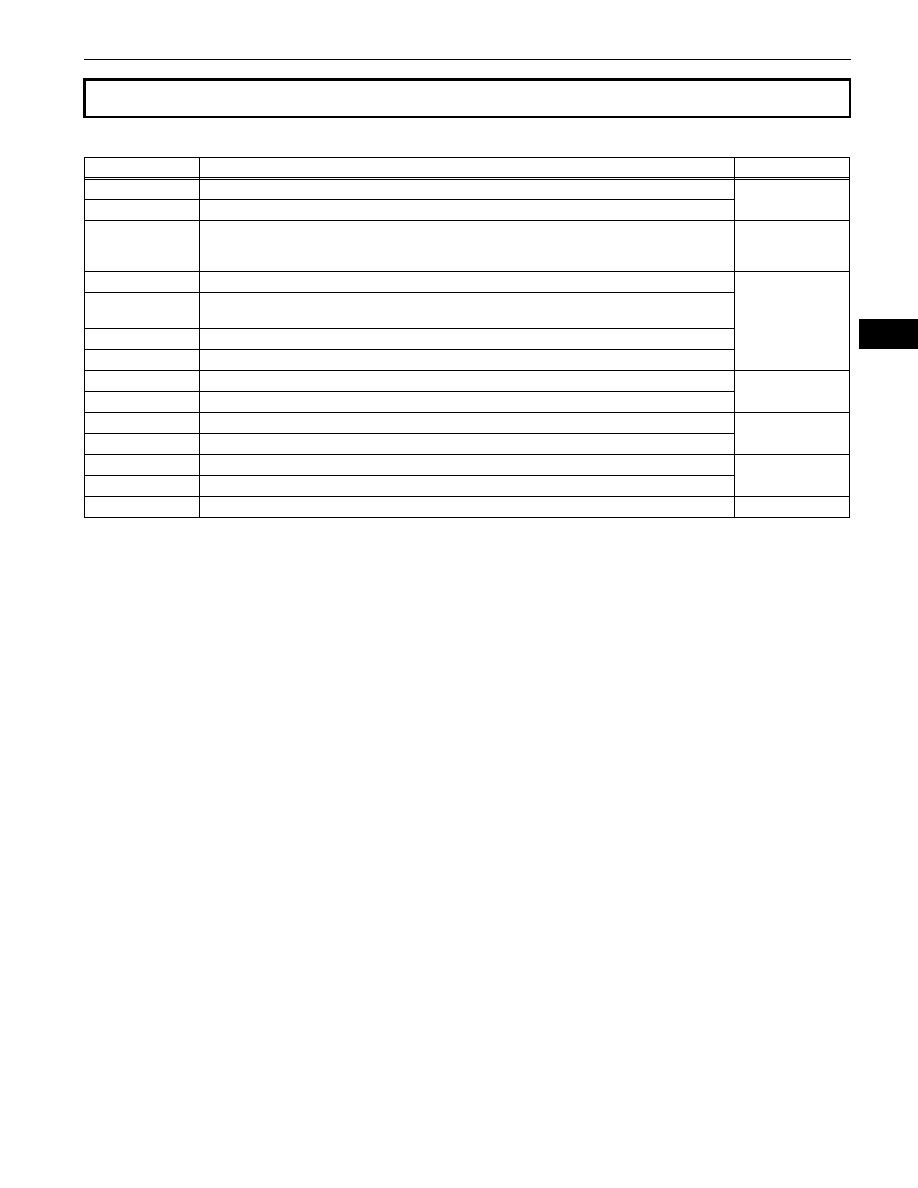

RELATED DTCS

If any EVAP system DTCs are set, the malfunctioning area can be determined using the table below.

EVAP System

DTCs

Monitoring Items

See Page

P043E

Reference orifice clogged (built into canister pump module)

P043F

Reference orifice high-flow (built into canister pump module)

P0441

•

Purge VSV (Vacuum Switching Valve) stuck closed

•

Purge VSV stuck open

•

Purge flow

P0450

Canister pressure sensor (built into canister pump module) voltage abnormal fluctuation

P0451

•

Canister pressure sensor (built into canister pump module) noise

•

Canister pressure sensor (built into canister pump module) signal becomes fixed/flat

P0452

Canister pressure sensor (built into canister pump module) voltage low

P0453

Canister pressure sensor (built into canister pump module) voltage high

P0455

EVAP gross leak

P0456

EVAP small leak

P2401

Leak detection pump stuck OFF (built into canister pump module)

P2402

Leak detection pump stuck ON (built into canister pump module)

P2419

Vent valve stuck closed (built into canister pump module)

P2420

Vent valve stuck open (vent) (built into canister pump module)

P2610

Soak timer (built into ECM)