Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 84

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–291

ES

DESCRIPTION

The throttle actuator is operated by the ECM, and opens and closes the throttle valve using gears. The

opening angle of the throttle valve is detected by the Throttle Position (TP) sensor, which is mounted on

the throttle body. The TP sensor provides feedback to the ECM in order that it can control the throttle

actuator, and therefore the throttle valve, appropriately in response to driver inputs.

HINT:

This ETCS (Electronic Throttle Control System) does not use a throttle cable.

MONITOR DESCRIPTION

The ECM determines that there is a malfunction in the ETCS when the throttle valve remains at a fixed

angle despite a high drive current from the ECM. The ECM illuminates the MIL and sets a DTC.

If the malfunction is not repaired successfully, a DTC is set when the accelerator pedal is fully depressed

and released quickly (to fully open and close the throttle valve) after the engine is next started.

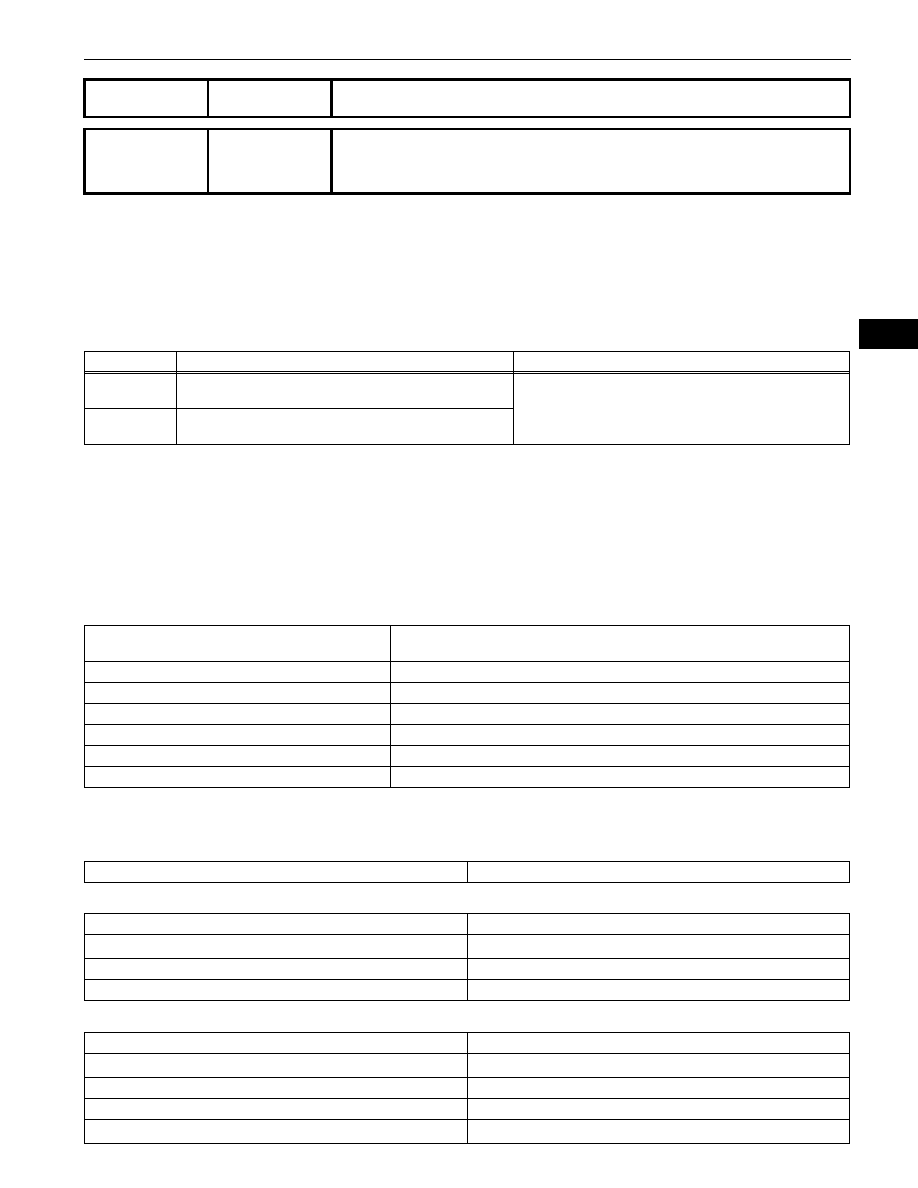

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

ALL:

P2111 (Throttle actuator stuck open):

P2112 (Throttle actuator stuck closed):

DTC

P2111

Throttle Actuator Control System - Stuck Open

DTC

P2112

Throttle Actuator Control System - Stuck

Closed

DTC No.

DTC Detection Conditions

Trouble Areas

P2111

ECM signals throttle actuator to close, but stuck (1 trip

detection logic)

•

Throttle actuator

•

Throttle body assembly

•

Throttle valve

P2112

ECM signals throttle actuator to open, but stuck (1 trip

detection logic)

Related DTCs

P2111: Throttle actuator stuck open

P2112: Throttle actuator stuck closed

Required Sensors/Components (Main)

Throttle actuator

Required Sensors/Components (Related)

-

Frequency of Operation

Continuous

Duration

0.5 seconds

MIL Operation

Immediate

Sequence of Operation

None

Monitor runs whenever following DTCs not present

None

All of following conditions met

-

System guard

*

ON

Throttle motor current

2 A or more

Throttle motor close duty

80 % or more

All of following conditions met

-

System guard

*

ON

Throttle motor current

2 A or more

Throttle motor open duty

80 % or more

*

System guard set when following conditions met

-