Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 61

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–199

ES

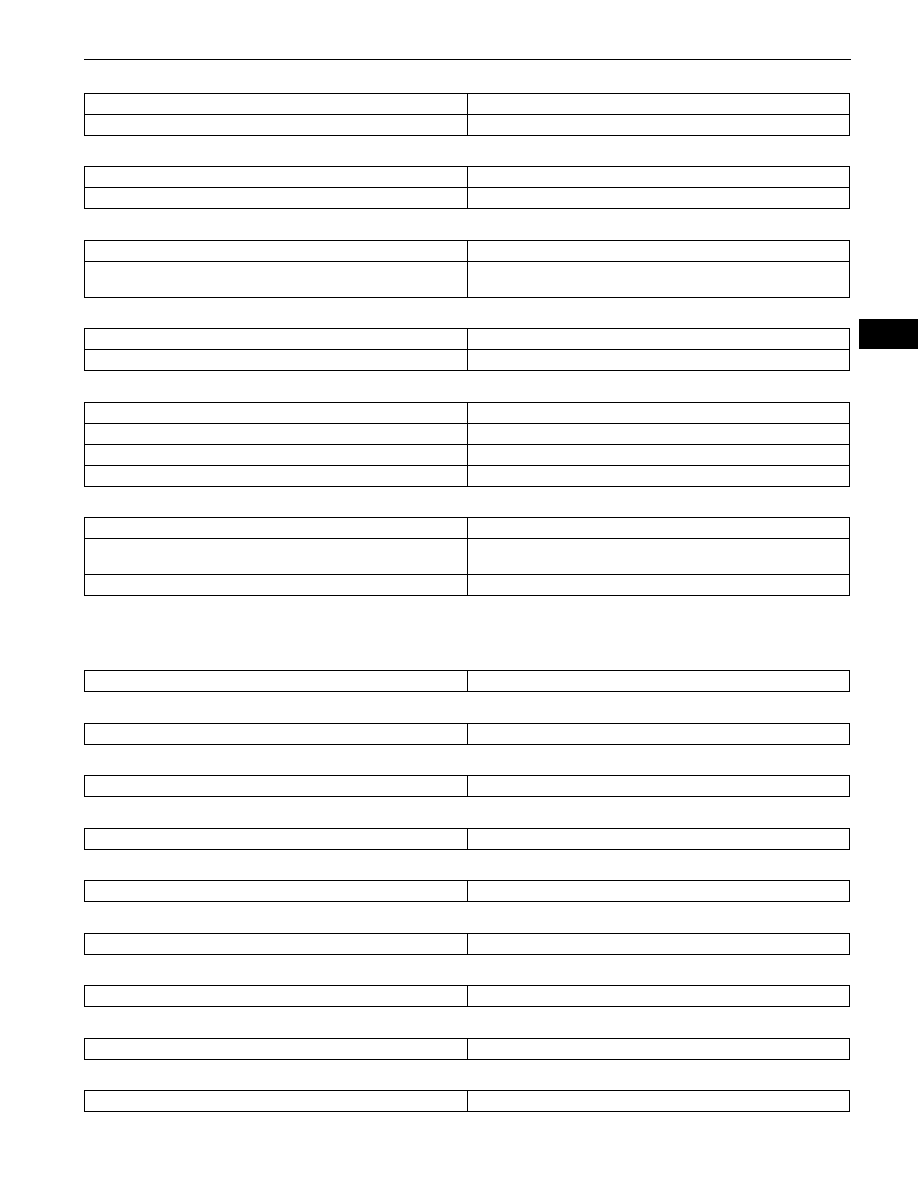

VVT Sensor Range Check:

Camshaft Position/Crankshaft Position Misalignment:

VVT Sensor Range Check (Fluctuating, Low voltage, High voltage):

VVT Sensor Range Check (While starting engine):

VVT Sensor Range Check (After starting engine):

VVT Sensor Range Check (Fluctuating, Low voltage, High voltage):

TYPICAL MALFUNCTION THRESHOLDS

VVT Sensor Range Check:

Camshaft Position/Crankshaft Position Misalignment:

VVT Sensor Range Check (Fluctuating):

VVT Sensor Range Check (Low voltage):

VVT Sensor Range Check (High voltage):

VVT Sensor Range Check (While starting engine):

VVT Sensor Range Check (After starting engine):

VVT Sensor Range Check (Fluctuating):

VVT Sensor Range Check (Low voltage):

Starter

ON

Minimum battery voltage while starter ON

Less than 11 V

Engine RPM

600 rpm or more

Starter

OFF

Starter

OFF

Ignition switch ON and time after ignition switch changed from OFF to

ON

2 seconds or more

Starter

ON

Battery voltage while starter ON once at least

Less than 11 V

Engine RPM

600 rpm or more

Starter

OFF

Battery voltage

8 V or more

Ignition switch

ON

Starter

OFF

Ignition switch ON and time after ignition switch changed from OFF to

ON

2 seconds or more

Battery voltage

8 V or more

VVT sensor signal

No signal

Camshaft position and crankshaft position phases

Mis-aligned

VVT sensor voltage

Less than 0.3 V, or more than 4.7 V

VVT sensor voltage

Less than 0.3 V

VVT sensor voltage

More than 4.7 V

VVT sensor signal

No signal

VVT sensor signal

No signal

VVT sensor voltage

Less than 0.3 V, or more than 4.7 V

VVT sensor voltage

Less than 0.3 V