Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 11

1GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR

EC–25

EC

INSTALLATION

1.

INSTALL HEATED OXYGEN SENSOR

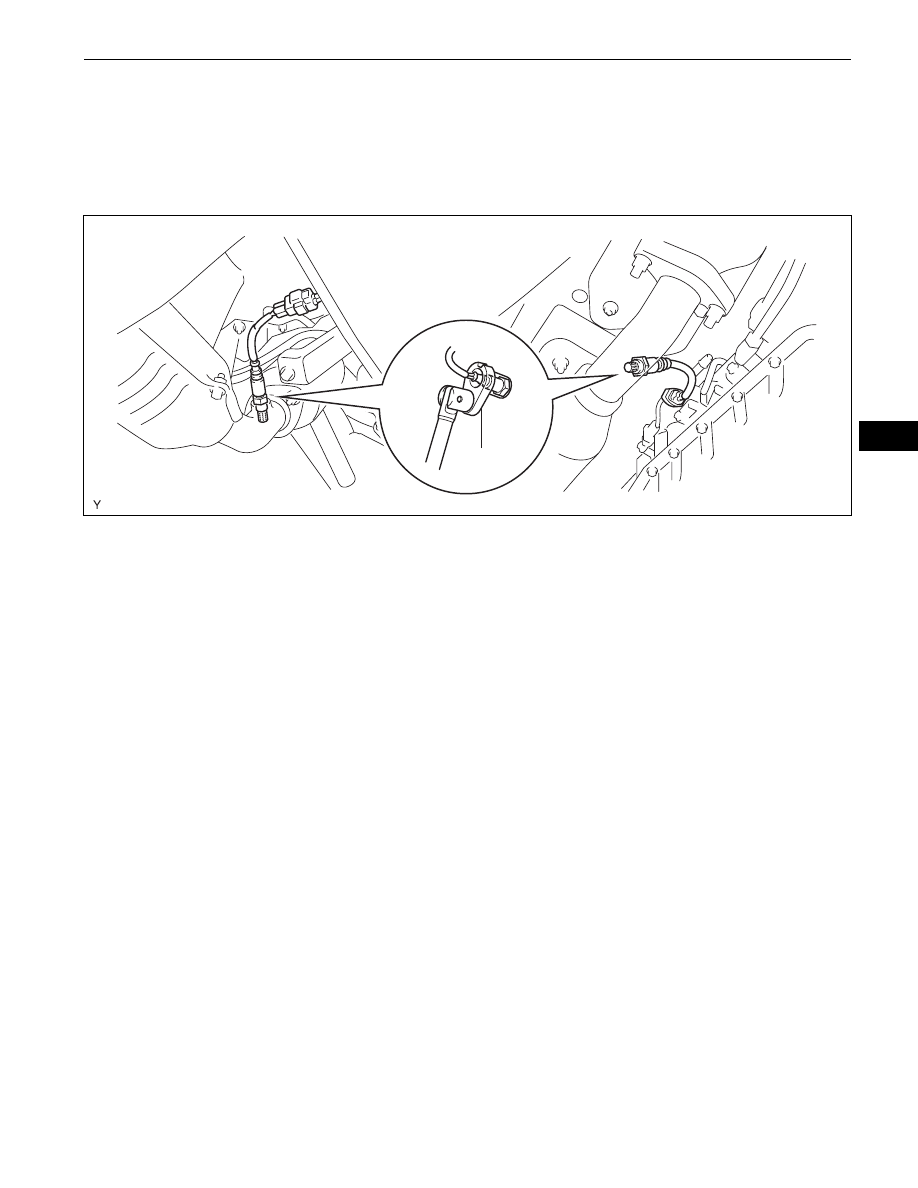

(a) Using SST, install the 2 heated oxygen sensors onto

the exhaust pipe.

SST

09224-00010

Torque: 44 N*m (449 kgf*cm, 33 ft.*lbf)

(b) Connect the 2 heated oxygen sensor connectors.

2.

CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

Torque: 3.9 N*m (40 kgf*cm, 35 in.*lbf)

SST

For RH side:

For LH side:

A128844E01