содержание .. 685 686 687 688 ..

Toyota Sequoia (2005). Manual - part 687

B16499

Fulcrum

Length

30 cm

SST

B02714

CORRECT

WRONG

Delivery Pipe

O–Ring

B04939

Delivery

Pipe

Intake

Manifold

O–Ring

Grommet

Injector

Insulator

B17532

Quick Type

Disconnect

B11684

Quick Type

Push

Pull

–

SFI

SFI SYSTEM

SF–3

2737

(3)

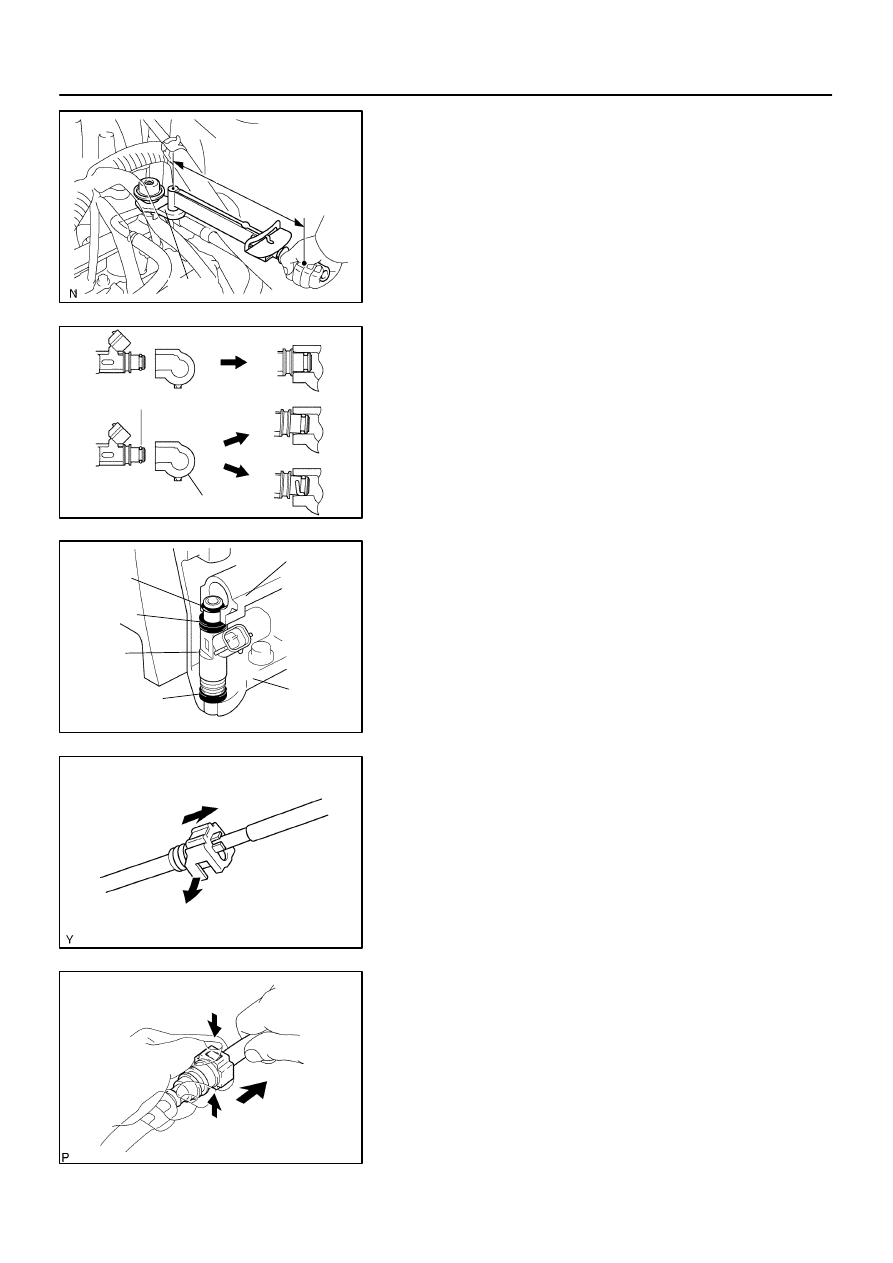

Using SST, tighten the union bolt to the specified

torque.

SST

09612–24014 (09617–24011)

Torque:

33 N·m (340 kgf·cm, 24 ft·lbf) for use with SST

39 N·m (400 kgf·cm, 29 ft·lbf)

HINT:

Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

(c)

Observe the following precautions when removing or

installing the injectors.

(1)

Never reuse the O–ring.

(2)

When placing a new O–ring on the injector, take

care not to damage it in any way.

(3)

Coat a new O–ring with spindle oil or gasoline be-

fore installing. Never use engine, gear or brake oil.

(d)

Install the injector to the delivery pipe and intake manifold

as shown in the illustration.

Before installing the injector, apply spindle oil or gasoline

on the place where the delivery pipe or the intake man-

ifold touches the O–ring of the injector.

(e)

Observe the following when disconnecting the fuel tube

connector (quick type):

(1)

Check if there is any dirt in the pipe and around the

connector before disconnecting the fuel tube con-

nector. If necessary, clean the dirt away.

(2)

Disconnect the fuel pipe clamp from the connector.

(3)

Be sure to disconnect them by hand.

(4)

When the connector and the pipe are stuck, push

and pull the connector. Then disconnect and pull it

out. Do not use any tools at this time.

(5)

Check if there is any dirt or other foreign matter on

the seal surface of the disconnected pipe. If neces-

sary, clean the dirt away.

(6)

Do not damage the disconnected pipe and connec-

tor and prevent intrusion of foreign objects by cover-

ing them with a plastic bag.