содержание .. 237 238 239 240 ..

Toyota Sequoia (2005). Manual - part 239

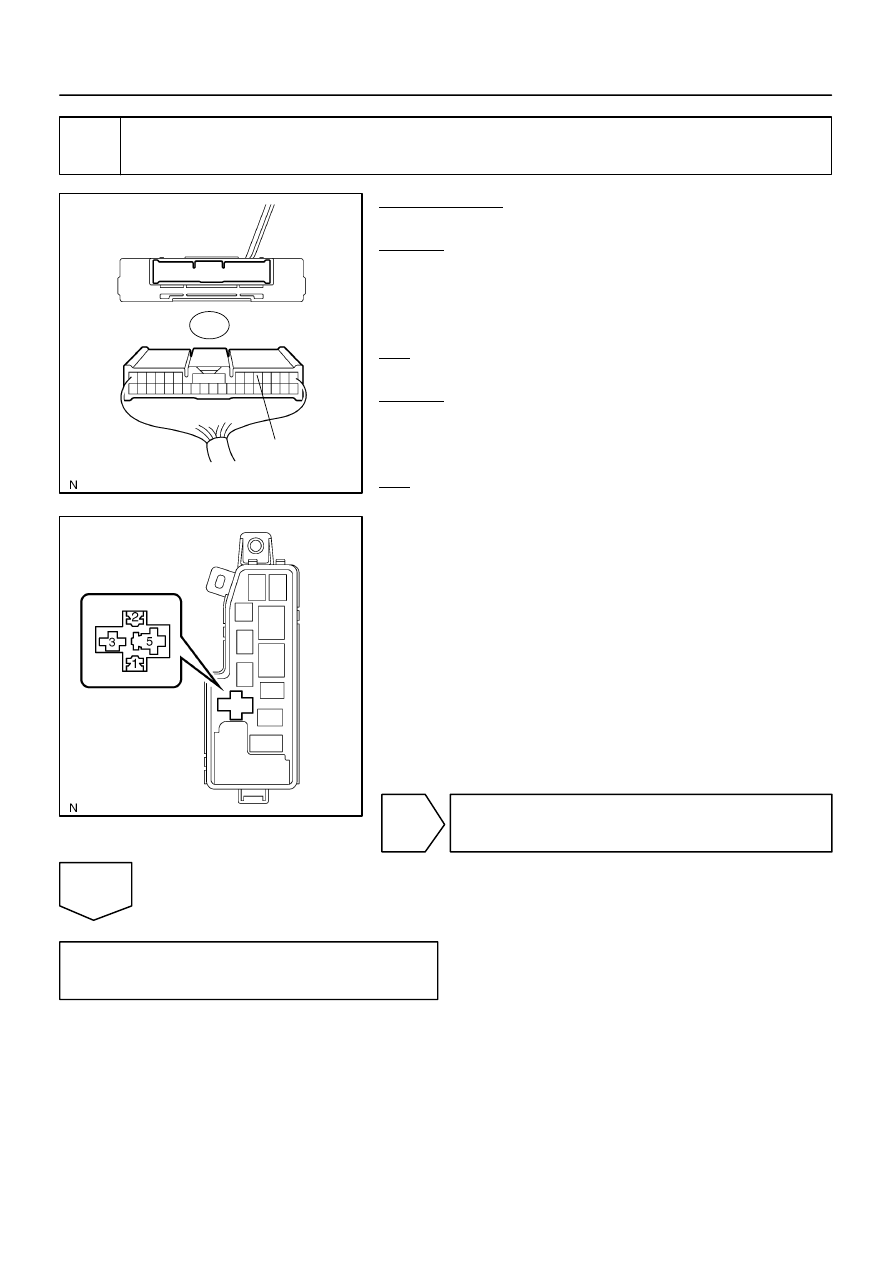

F16805

S25

Suspension Control ECU

Wire Harness View:

RC

F19460

Engine Room R/B No. 2:

AIR SUS

Relay Terminal

–

DIAGNOSTICS

AIR SUSPENSION SYSTEM

DI–751

945

3

Check harness and connector (Engine room R/B – Suspension control ECU,

Body ground).

PREPARATION:

Disconnect the ECU connector.

CHECK:

Check for an open or short circuit in the harness and the con-

nector between the AIR SUS relay terminal 1 of the engine

room R/B and terminal S25–5 (RC) of the suspension control

ECU.

OK:

There is no open or short in the wire harness.

CHECK:

Check for an open circuit in the harness and the connector be-

tween the AIR SUS relay terminal 2 of the engine room R/B and

body ground.

OK:

There is no open in the wire harness.

NG

Repair or replace harness or connector.

OK

Replace suspension control ECU

(See page

).