содержание .. 100 101 102 103 ..

Toyota Sequoia (2005). Manual - part 102

–

DIAGNOSTICS

ENGINE

DI–211

405

MONITOR DESCRIPTION

If there are no signals from the crankshaft sensor even though the engine is revolving, the ECM interprets

this as a malfunction of the sensor.

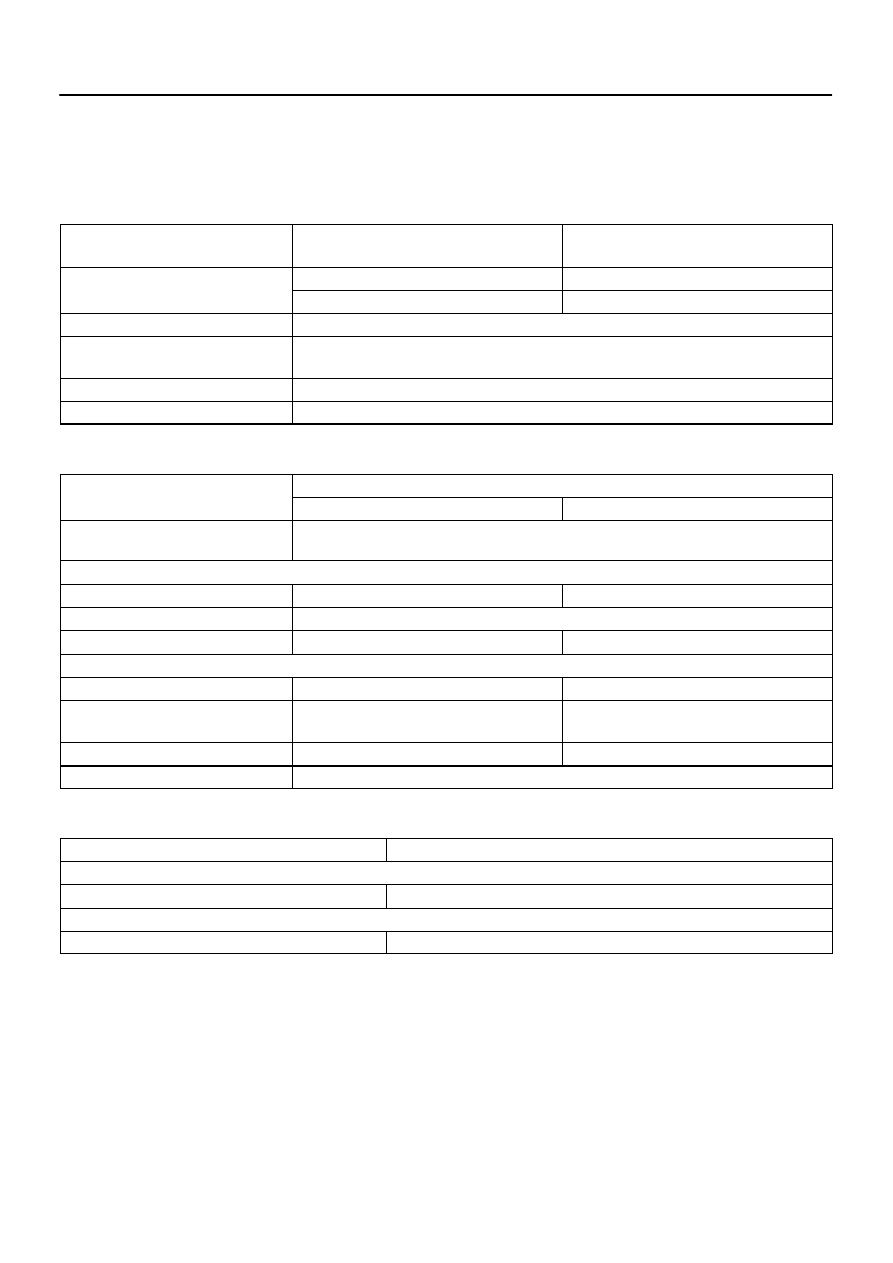

MONITOR STRATEGY

Related DTCs

P0335

Crankshaft position sensor range check or ratio-

nality

R

i d

/

t

Main sensors/components

Crankshaft position sensor

Required sensors/components

Related sensors/components

Engine speed sensor

Frequency of operation

Continuous

Duration

Case 1: 0.016 sec.

Case 2: 3 times

MIL operation

Immediate

Sequence of operation

None

TYPICAL ENABLING CONDITIONS

It

Specification

Item

Minimum

Maximum

The monitor will run whenever this DTC is

not present

See page

Case 1:

Engine speed

450 rpm

–

Starter

OFF

Time after starter ON to OFF

3 sec.

–

Case 2:

Time after starter ON to OFF

0.3 sec.

–

Number of camshaft position sensor sig-

nal pulse

3

–

Battery voltage

7 V

–

Ignition switch

ON

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

Case 1:

Engine speed signal

No signal for 0.016 sec.

Case 2:

Number of crankshaft position sensor signal pulse

44 or less, or 58 or more