содержание .. 81 82 83 84 ..

Toyota Sequoia (2005). Manual - part 83

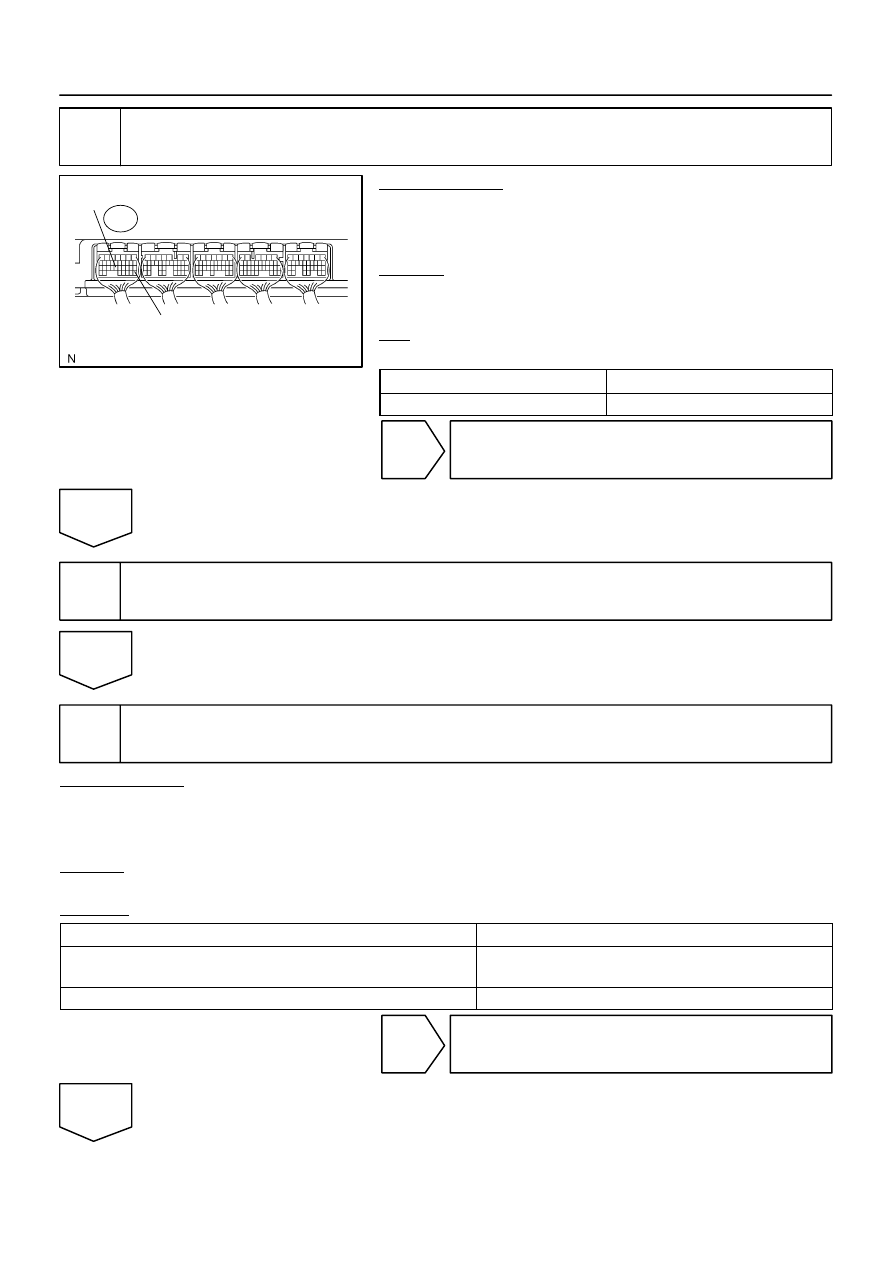

B17411

E2

VC

E8

ECM Connector

–

DIAGNOSTICS

ENGINE

DI–135

329

3

Check voltage between terminals VC and E2 of ECM connector.

PREPARATION:

(a)

Disconnect the T14 throttle control motor and sensor con-

nector.

(b)

Turn the ignition switch ON.

CHECK:

Measure the voltage between the specified terminals of the E8

ECM connector.

OK:

Standard:

Tester Connection

Specified Condition

VC (E8–23) – E2 (E8–28)

4.5 to 5.5 V

NG

Replace ECM (See page

OK

4

Replace throttle body (See page

Go

5

Check if DTC output recur.

PREPARATION:

(a)

).

(b)

Start the engine.

(c)

Run the engine at idle for 15 seconds or more.

CHECK:

Read the DTC.

RESULT:

Display (DTC Output)

Proceed to

”P0120, P0122, P0123, P0220, P0222, P0223 and/or P2135” are output

again

A

No DTC output

B

B

System is OK.

A