Suzuki: Engine K6A-YH6. Manual - part 22

7-42

REPAIR

7

Figure 7-97

NOTE

Apply clean oil to the connecting rod cap bearing and

crankshaft journal.

9.

Install connecting rod cap (17) and nuts (18). Tighten

to specification.

Connecting Rod Torque: 24 lb-ft (33 N•m)

10. Install crankshaft baffle. (See “Crankshaft Baffle” on

11. Install oil pump pickup. (See “Oil Pump Pickup” on

12. Install oil pan. (See “Oil Pan” on page 7-30.)

13. Install cylinder head. (See “Cylinder Head” on

Lower Crankcase, Cylinder Block,

and Crankshaft

Disassembly

See Figures 7-98 through 7-101.

1.

Remove cylinder head. (See “Cylinder Head” on

page 7-24.)

2.

Remove oil pan. (See “Oil Pan” on page 7-30.)

3.

Remove oil pump pickup. (See “Oil Pump Pickup” on

page 7-31.)

4.

Remove crankshaft baffle. (See “Crankshaft Baffle”

on page 7-32.)

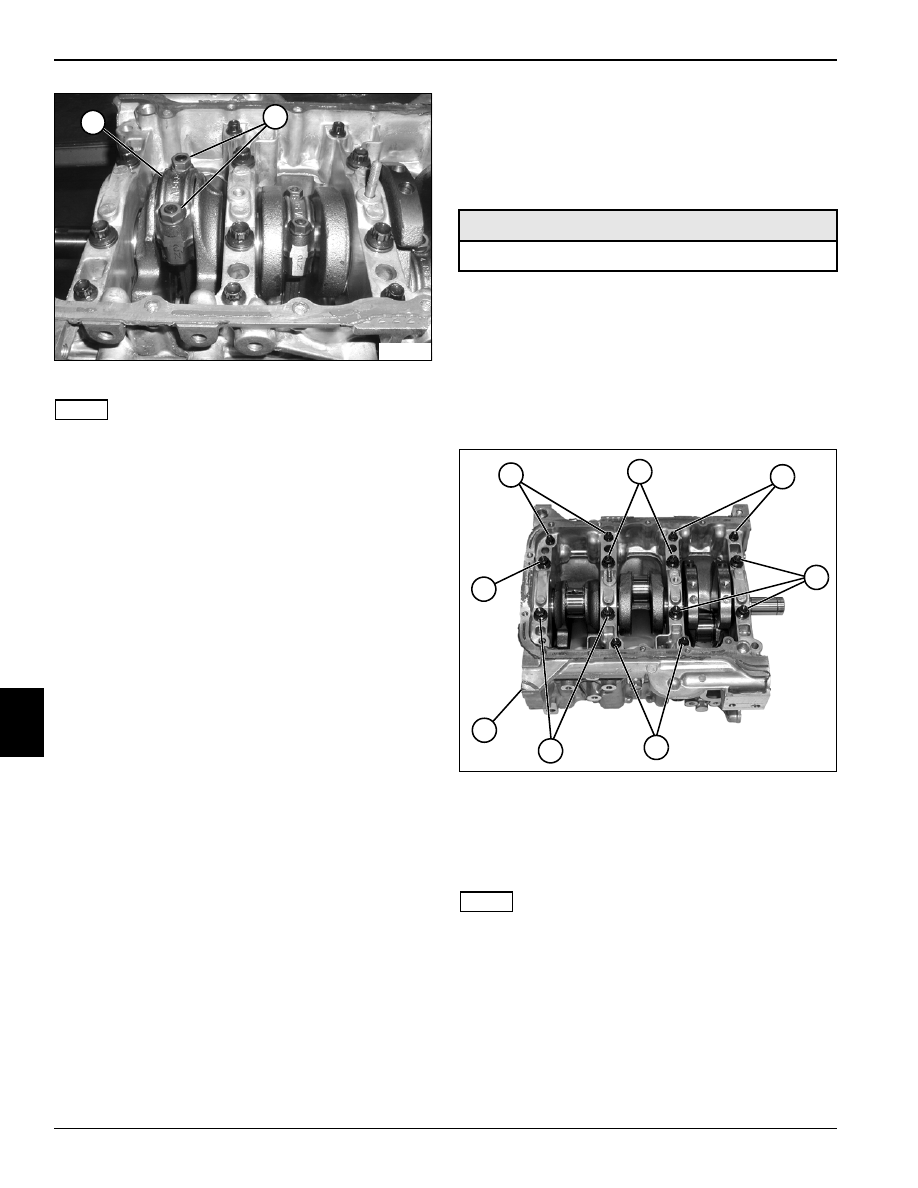

Figure 7-98

5.

Using a 12-point 8 mm socket, remove six screws

and washers (1).

6.

Using a 12-point 10 mm socket, remove eight screws

and washers (2).

NOTE

The lower crankcase is located using four dowel pins and

is sealed to the cylinder block using Three Bond ™ 1215

sealant. The lower crankcase must be lifted off square.

7.

Use a soft face mallet to loosen lower crankcase (3)

from cylinder block. Remove lower crankcase from

cylinder block. Be sure to lift lower crankcase off

square.

TN0752

17

18

Required Tools

8 and 10 mm 12-point sockets

TN0755

1

1

2

2

1

2

3

2