Subaru Legacy IV (2008 year). Manual - part 485

ME(H6DO)-66

Cylinder Block

MECHANICAL

B: INSTALLATION

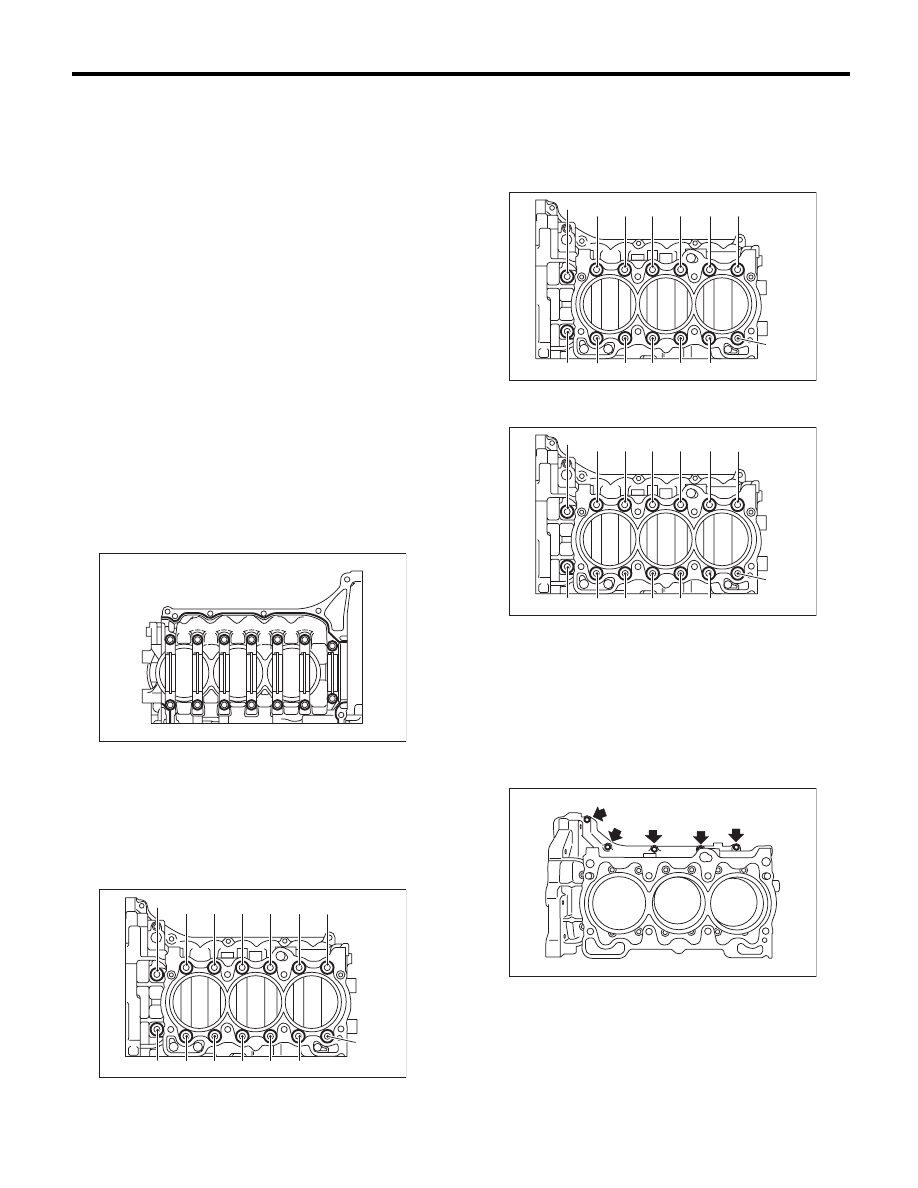

1) After setting the cylinder block to ST, install the

crankshaft bearing.

ST

18232AA000

ENGINE STAND

NOTE:

Remove oil on the mating surface of cylinder block

before installation. Apply a coat of engine oil to the

bearing and crankshaft journal.

2) Position the crankshaft on the cylinder block

(RH).

3) Apply liquid gasket to the mating surfaces of cyl-

inder block (RH), and position the cylinder block

(LH).

NOTE:

• Do not allow liquid gasket to run over to oil pas-

sages, bearing grooves, etc.

• Install within 5 minutes after applying liquid gas-

ket.

Liquid gasket:

THREE BOND 1217G (Part No. K0877Y0100)

or equivalent

Applying liquid gasket diameter:

1.0

r

0.2 mm (0.039

r

0.008 in)

4) Apply a coat of engine oil to the washer and bolt

thread.

5) Tighten all bolts in the numerical order as shown

in the figure.

Tightening torque:

(1) — (11), (13): 25 N·m (2.5 kgf-m, 18.4 ft-lb)

(12), (14): 20 N·m (2.0 kgf-m, 14.8 ft-lb)

6) Retighten all bolts in the numerical order as

shown in the figure.

Tightening torque:

(1) — (11), (13): 25 N·m (2.5 kgf-m, 18.4 ft-lb)

(12), (14): 20 N·m (2.0 kgf-m, 14.8 ft-lb)

7) Tighten all bolts 90° — 110° in the numerical or-

der as shown in the figure.

8) Install the upper bolt to cylinder block.

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

NOTE:

After tightening the cylinder block connecting bolts,

remove the liquid gasket which is running over to

the sealing surface for rear chain cover and oil pan

upper.

ME-00567

(1)

(6)

(8)

(3)

(9)

(2)

(4)

(5)

(7)

(10)

(11)

(12)

(13)

(14)

ME-00568

(1)

(6)

(8)

(3)

(9)

(2)

(4)

(5)

(7)

(10)

(11)

(12)

(13)

(14)

ME-00568

(1)

(6)

(8)

(3)

(9)

(2)

(4)

(5)

(7)

(10)

(11)

(12)

(13)

(14)

ME-00568

ME-00569