Subaru Legacy IV (2008 year). Manual - part 141

EN(H4SO)(diag)-167

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

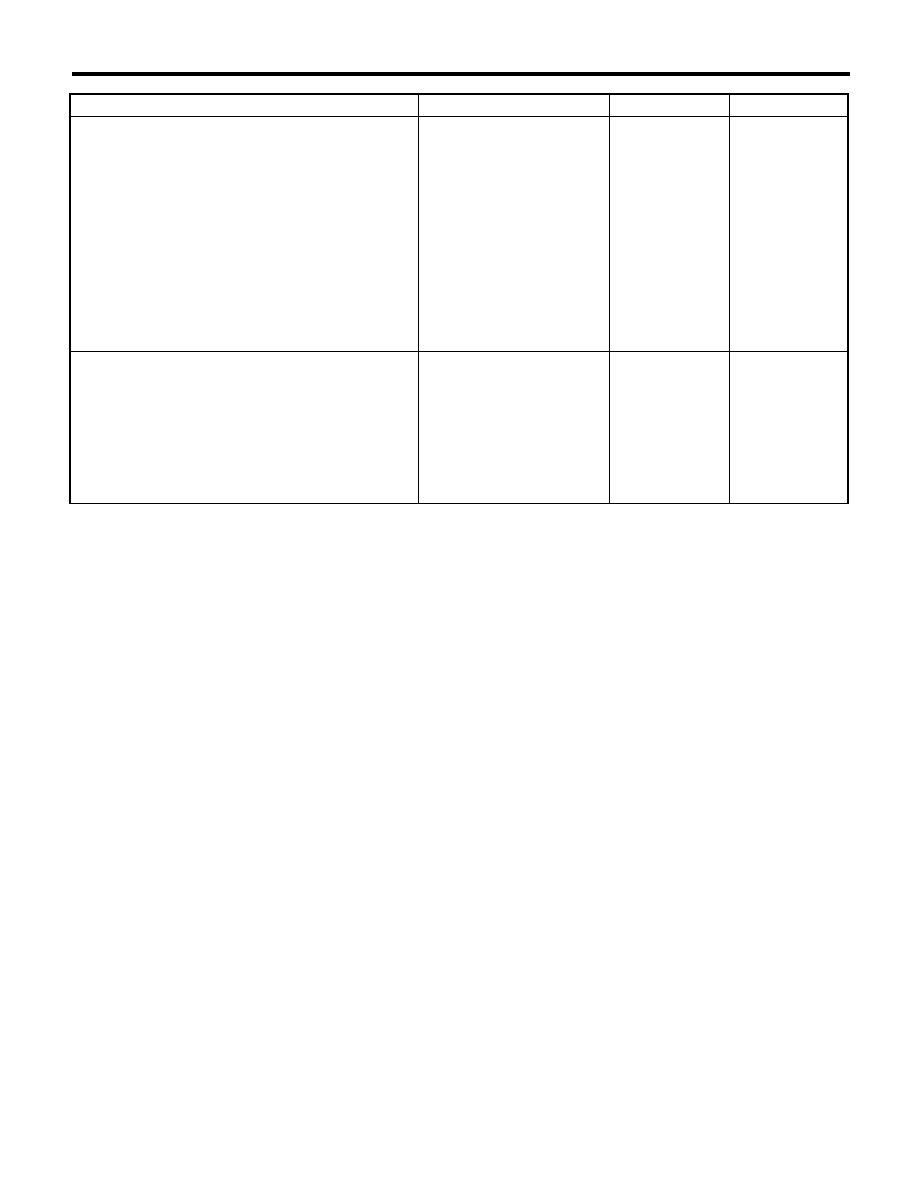

Step

Check

Yes

No

1

CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of oil temperature sensor sig-

nal using Subaru Select Monitor or general

scan tool.

NOTE:

• SUBARU SELECT MONITOR

For detailed operation procedure, refer to

“READ CURRENT DATA FOR ENGINE”. <Ref.

to EN(H4SO)(diag)-33, Subaru Select Moni-

tor.>

• General Scan Tool

For detailed operation procedures, refer to the

general scan tool operation manual.

Is the oil temperature 215°C

(419°F) or more?

Go to step 2.

Even if DTC is

detected, the cir-

cuit has returned to

a normal condition

at this time. Repro-

duce the failure,

and then perform

the diagnosis

again.

NOTE:

In this case, tem-

porary poor con-

tact of connector

may be the cause.

2

CHECK HARNESS BETWEEN ECM AND OIL

TEMPERATURE SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM and oil

temperature sensor.

3) Measure the resistance between ECM and

chassis ground.

Connector & terminal

(B134) No. 23 — Chassis ground:

Is the resistance 1 M

: or

more?

Replace the oil

temperature sen-

sor. <Ref. to

FU(H4SO)-34, Oil

Temperature Sen-

sor.>

Repair the short

circuit to ground in

harness between

ECM and oil tem-

perature sensor.