Subaru Legacy IV (2008 year). Manual - part 25

PM-40

Brake Line

PERIODIC MAINTENANCE SERVICES

3) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 490 N (50 kgf, 110 lb) load and measure the

distance between the brake pedal and steering

wheel. With the brake pedal released, measure the

distance between pedal and steering wheel again.

The pedal stroke is normal if the difference be-

tween two measured values is the specified value

or less. If the measured value is the specification or

more, there is possibility of entering air in hydraulic

unit.

Brake pedal stroke A:

95 mm (3.7 in)/ 490 N (50 kgf, 110 lb) or less

4) Check to see if air is in the hydraulic brake line

by the feel of pedal operation. If air appears to exist

in the line, bleed it from the system.

5) Check for even operation of all brakes, using a

brake tester or by driving the vehicle for a short dis-

tance on a straight road.

3. BRAKE SERVO SYSTEM

1) With the engine off, depress the brake pedal

several times applying the same pedal force. Make

sure the travel distance should not change.

2) With the brake pedal depressed, start the en-

gine. Make sure the pedal should move slightly to-

ward the floor.

3) With the brake pedal depressed, stop the engine

and keep the pedal depressed for 30 seconds.

Make sure the pedal height should not change.

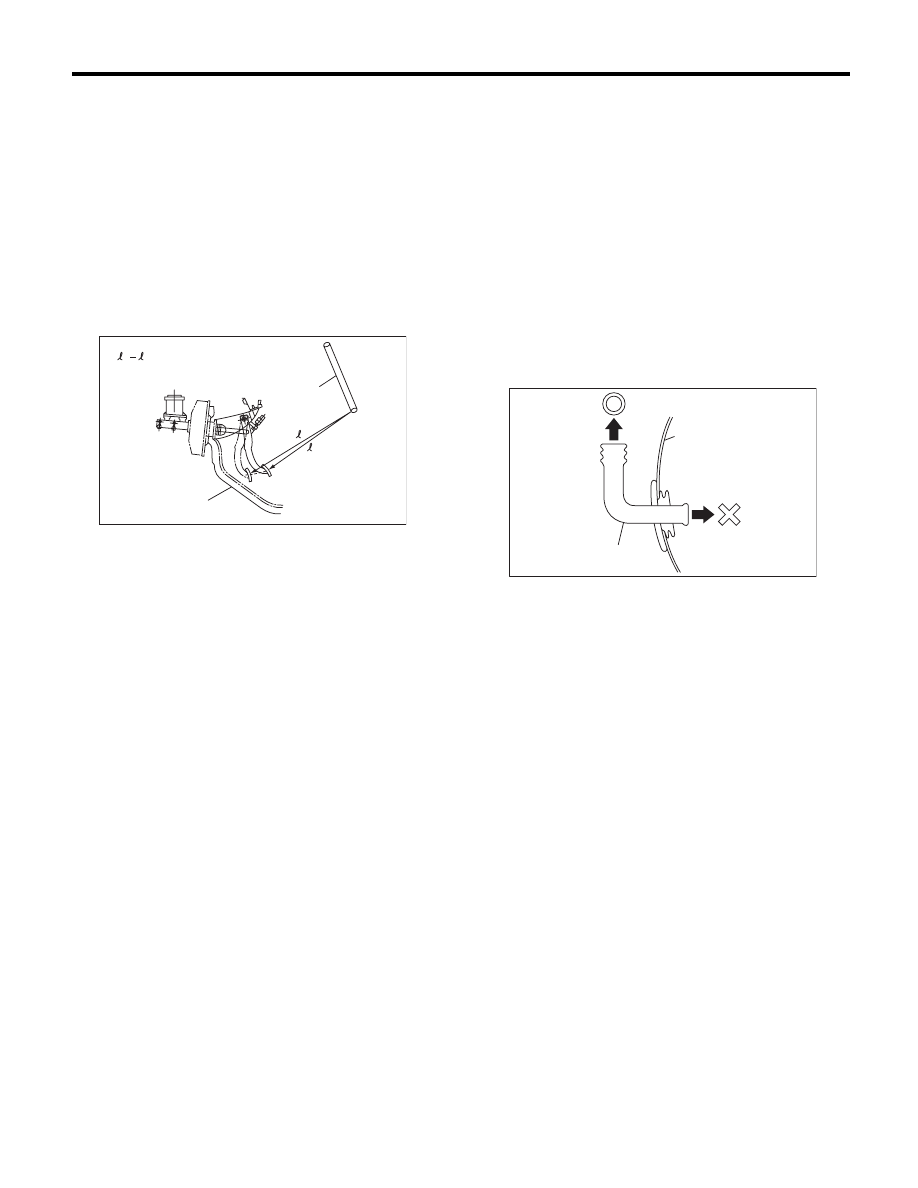

4) A check valve is incorporated into the brake

booster nipple part. Disconnect the vacuum hose to

inspect function of check valve.

Make sure air flows from the booster end to engine

end but does not flow in the opposite direction in

the check valve.

5) Check the vacuum hose for cracks or other dam-

age.

NOTE:

When installing the vacuum hose on the engine

and brake booster, do not use soapy water or lubri-

cating oil on their connections.

6) Check the vacuum hose to make sure it is tightly

secured.

(A) Steering wheel

(B) Toe board

PM-00045

(B)

(A)

= A

1

1

2

2

(A) Brake booster

(B) Check valve

(C) Engine side

(D) Brake booster side

PM-00260

(D)

(A)

(C)

(B)