Subaru Legacy III (2000-2003 year). Manual - part 836

PS-32

POWER ASSISTED SYSTEM (POWER STEERING)

STEERING GEARBOX [LHD MODEL]

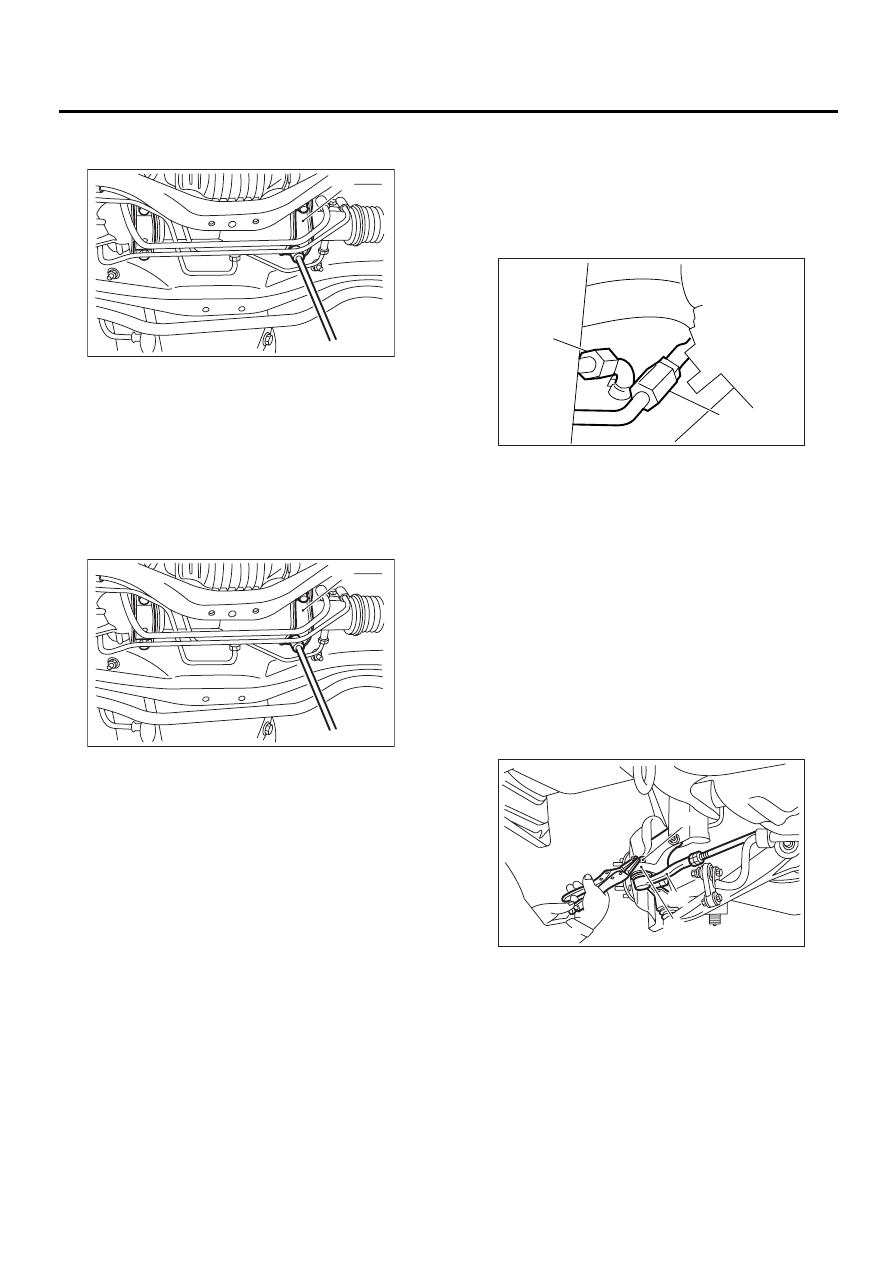

10) Remove clamp bolts securing gearbox to

crossmember, and remove gearbox.

B: INSTALLATION

1) Insert gearbox into crossmember, being careful

not to damage gearbox boot.

2) Tighten gearbox to crossmember bracket via

clamp with bolt to the specified torque.

Tightening torque:

59 N·m (6.0 kgf-m, 43 ft-lb)

3) Connect pipes C and D to pipe of gearbox.

NOTE:

Connect lower pipe C first, and upper pipe D sec-

ond.

CAUTION:

Be careful not to damage these pipes.

4) Install universal joint. <Ref. to PS-25, INSTAL-

LATION, Universal Joint.>

5) Connect tie-rod end and knuckle arm, and tight-

en with castle nut. Fit cotter pin into the nut and

bend the pin to lock.

Castle nut tightening torque:

Tighten to 27.0 N·m (2.75 kgf-m, 19.9 ft-lb),

and tighten further within 60

°°°°

until cotter

pin hole is aligned with a slot in the nut.

CAUTION:

When connecting, do not hit cap at the bottom

of tie-rod end with hammer.

6) Install front stabilizer to vehicle. <Ref. to FS-21,

INSTALLATION, Front Stabilizer.>

(1) Clamp

(1) Clamp

PS-00028

( 1 )

PS-00028

( 1 )

(1) Pipe C

(2) Pipe D

(1) Castle nut

(2) Tie-rod end

(3) Knuckle arm

( 1 )

( 2 )

PS-00205

PS-00043

( 1 )

( 2 )

( 3 )