Subaru Legacy III (2000-2003 year). Manual - part 824

BR-54

BRAKE

BRAKE PEDAL

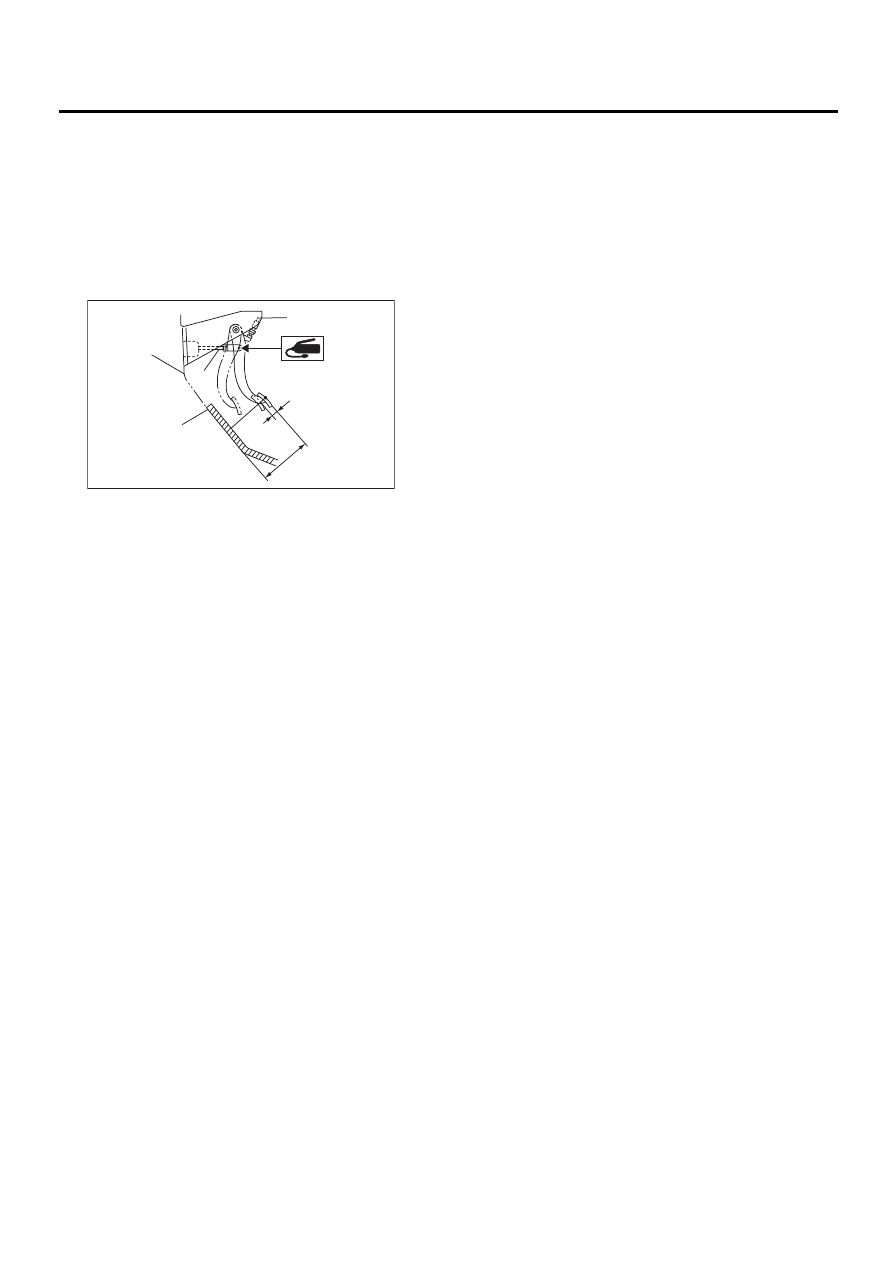

2) Check position of pedal pad.

Pedal height: L

AT: 158 mm (6.22 in)

MT: 153 mm (6.02 in)

Brake pedal free play: A

1 — 3 mm (0.04 — 0.12 in) [Depress brake

pedal pad with a force of less than 10 N (1

kgf, 2 lb).]

3) If it is not in specified value, adjust it by adjusting

brake booster operating rod length.

(1) Stop light switch

(2) Mat

(3) Toe board

(4) Brake booster operating rod

BR-00106

A

L

( 1 )

( 2 )

( 3 )

( 4 )