Subaru Legacy III (2000-2003 year). Manual - part 806

VDC-260

VDC (DIAGNOSTICS)

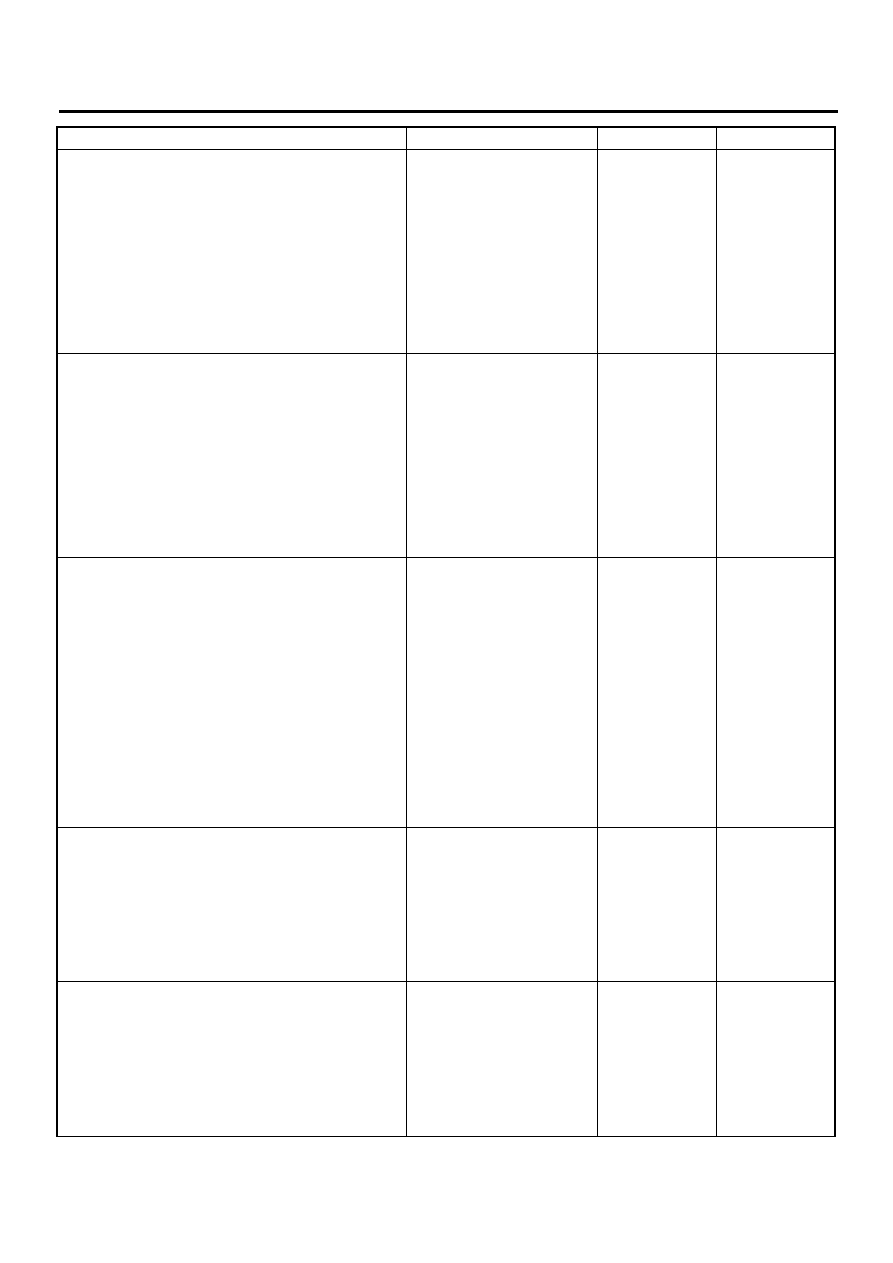

DIAGNOSTICS CHART WITH SELECT MONITOR

7

CHECK OPEN CIRCUIT IN YAW RATE AND

LATERAL G SENSOR OUTPUT HARNESS

AND GROUND HARNESS.

1) Connect connector to yaw rate and lateral

G sensor.

2) Disconnect connector from VDCCM.

3) Measure resistance between VDCCM con-

nector terminals.

Connector & terminal

(F87) No. 70 — No. 64:

Is the measured value within the specified

range?

4.3 — 4.9 k

Ω

Repair harness/

connector

between yaw rate

and lateral G sen-

sor and VDCCM.

8

CHECK GROUND SHORT IN YAW RATE

AND LATERAL G SENSOR HARNESS.

1) Disconnect connector from yaw rate and

lateral G sensor.

2) Measure resistance between VDCCM con-

nector and chassis ground.

Connector & terminal

(F87) No. 63 — Chassis ground:

(F87) No. 70 — Chassis ground:

(F87) No. 64 — Chassis ground:

Does the measured value exceed the spec-

ified value?

1 M

Ω

Repair harness

between yaw rate

and lateral G sen-

sor and VDCCM.

9

CHECK YAW RATE AND LATERAL G SEN-

SOR.

1) Turn ignition switch to OFF.

2) Remove yaw rate and lateral G sensor from

vehicle.

3) Connect connector to yaw rate and lateral

G sensor.

4) Connect connector to VDCCM.

5) Turn ignition switch to ON.

6) Measure voltage between yaw rate and lat-

eral G sensor connector terminals.

Connector & terminal

(R100) No. 5 (+) — No. 6 (

−−−−

):

Is the measured value within the specified

range when yaw rate and lateral G sensor

is horizontal?

2.3 — 2.7 V

Replace yaw rate

and lateral G sen-

sor. <Ref. to VDC-

22, Yaw Rate and

Lateral G Sensor.>

10

CHECK YAW RATE AND LATERAL G SEN-

SOR.

Measure voltage between yaw rate and lateral

G sensor connector terminals.

Connector & terminal

(R100) No. 5 (+) — No. 6 (

−−−−

):

Is the measured value within the specified

range when yaw rate and lateral G sensor is

inclined 90× to left?

3.3 — 3.7 V

Replace yaw rate

and lateral G sen-

sor. <Ref. to VDC-

22, Yaw Rate and

Lateral G Sensor.>

11

CHECK YAW RATE AND LATERAL G SEN-

SOR.

Measure voltage between yaw rate and lateral

G sensor connector terminals.

Connector & terminal

(R100) No. 5 (+) — No. 6 (

−−−−

):

Is the measured value within the specified

range when yaw rate and lateral G sensor is

inclined 90× to right?

1.3 — 1.7 V

Replace yaw rate

and lateral G sen-

sor. <Ref. to VDC-

22, Yaw Rate and

Lateral G Sensor.>

Step

Value

Yes

No