Subaru Legacy III (2000-2003 year). Manual - part 326

EN(H6DO)-106

ENGINE (DIAGNOSTICS)

DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE (DTC)

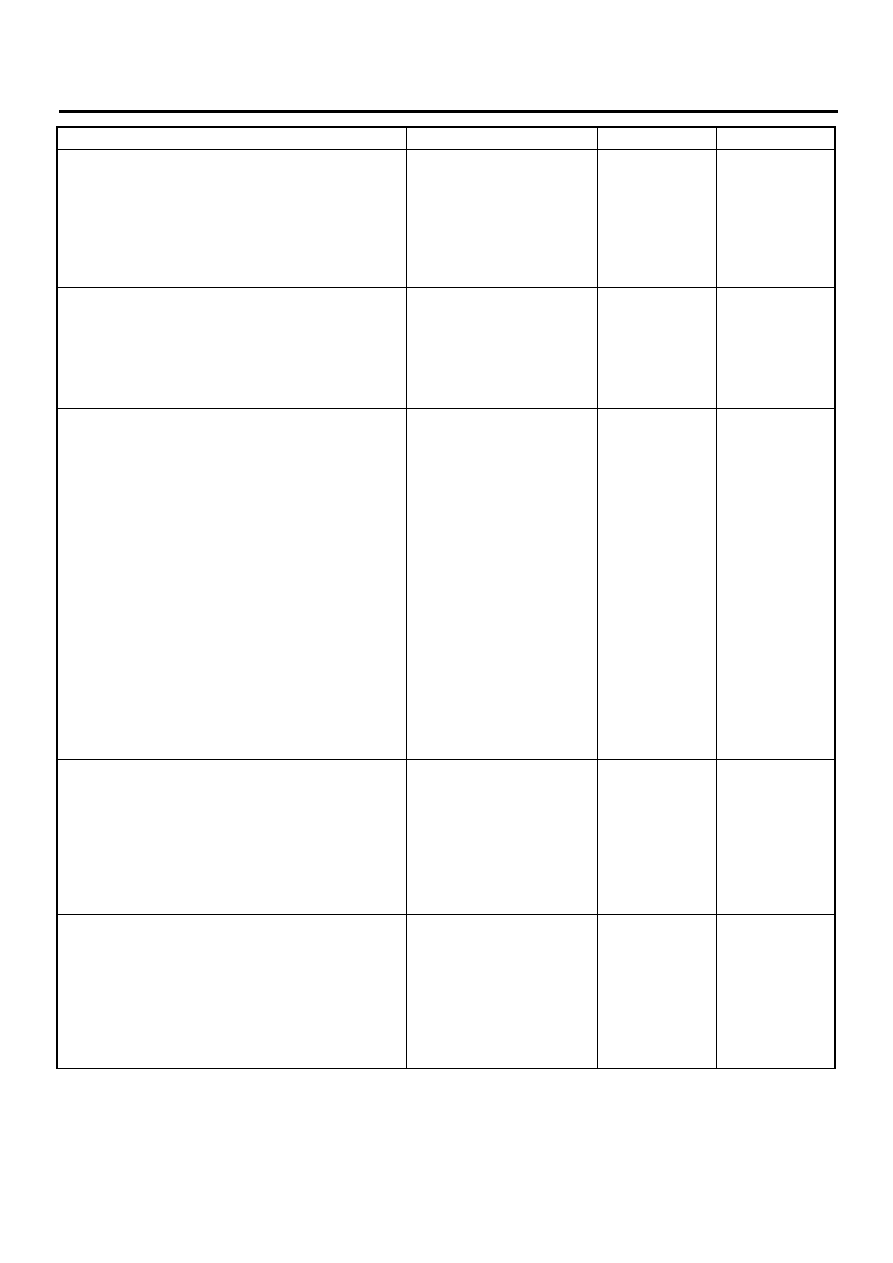

Step

Value

Yes

No

1

CHECK OUTPUT SIGNAL FROM ECM.

1) Turn ignition switch to ON.

2) Measure voltage between ECM connector

and chassis ground.

Connector & terminal

(B137) No. 4 (+) — Chassis ground (

−−−−

):

Does the measured value exceed the spec-

ified value?

8 V

2

CHECK OUTPUT SIGNAL FROM ECM.

Measure voltage between ECM connector and

chassis ground.

Connector & terminal

(B137) No. 5 (+) — Chassis ground (

−−−−

):

Does the measured value exceed the specified

value?

8 V

3

CHECK FRONT OXYGEN (A/F) SENSOR

HEATER CURRENT.

1) Turn ignition switch to OFF.

2) Repair battery short circuit in harness

between ECM and front oxygen (A/F) sen-

sor connector.

3) Turn ignition switch to ON.

4) Read data of front oxygen (A/F) sensor

heater current using Subaru Select Monitor

or the OBD-II general scan tool.

Does the measured value exceed the spec-

ified value?

NOTE:

• Subaru Select Monitor

For detailed operation procedure, refer to the

“READ CURRENT DATA FOR ENGINE”.

<Ref. to EN(H6DO)-34, Subaru Select Moni-

tor.>

• OBD-II general scan tool

For detailed operation procedure, refer to the

OBD-II General Scan Tool Instruction Manual.

2.3 A

Replace ECM.

<Ref. to

FU(H6DO)-46,

Engine Control

Module.>

END

4

CHECK OUTPUT SIGNAL FROM ECM.

Measure voltage between ECM connector and

chassis ground.

Connector & terminal

(B137) No. 4 (+) — Chassis ground (

−−−−

):

Does the voltage change more than the speci-

fied value by shaking harness and connector

of ECM while monitoring the value with voltage

meter?

8 V

Repair battery

short circuit in har-

ness between

ECM and front

oxygen (A/F) sen-

sor connector.

5

CHECK OUTPUT SIGNAL FROM ECM.

Measure voltage between ECM connector and

chassis ground.

Connector & terminal

(B137) No. 5 (+) — Chassis ground (

−−−−

):

Does the voltage change more than the speci-

fied value by shaking harness and connector

of ECM while monitoring the value with voltage

meter?

8 V

Repair battery

short circuit in har-

ness between

ECM and front

oxygen (A/F) sen-

sor connector.

END