Subaru Legacy III (2000-2003 year). Manual - part 297

SC(H6DO)-12

STARTING/CHARGING SYSTEMS

STARTER

6. SWITCH ASSEMBLY OPERATION

1) Connect the terminal S of switch assembly to

positive terminal of battery with a lead wire, and

starter body to ground terminal of battery. The pin-

ion should be forced endwise on shaft.

CAUTION:

With the pinion forced endwise on shaft, starter

motor can sometimes rotate because current

flows, through pull-in coil, to motor. This is not

a problem.

2) Disconnect the connector from terminal M, and

then connect the positive terminal of battery and

terminal M using a lead wire and ground terminal to

starter body.

In this test set up, the pinion should return to its

original position even when it is pulled out with a

screwdriver.

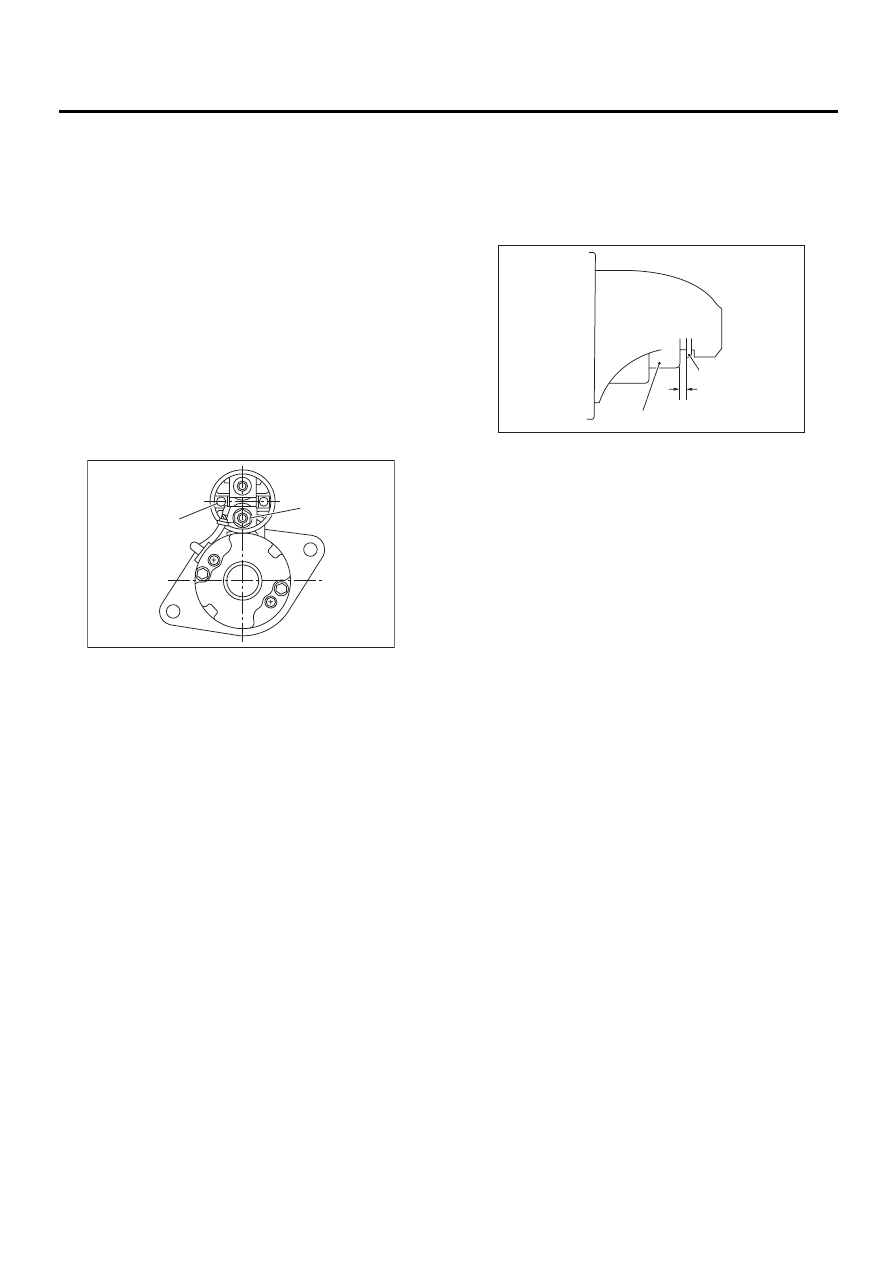

7. PINION GAP

1) Measure pinion gap while the pinion is pulled out

as shown in the figure.

Pinion gap:

0.5 — 2.0 mm (0.020 — 0.079 in)

If the motor is running with the pinion forced end-

wise on shaft, disconnect the connector from termi-

nal M of switch assembly, and then connect

terminal M to ground terminal (

−

) of battery with a

lead wire. Next, gently push the pinion back with

your fingertips, and then measure the pinion gap.

2) If the pinion gap is outside specified range, re-

move or add number of adjustment washers used

on the mounting surface of switch assembly until

correct pinion gap is obtained.

(A) Terminal S

(B) Terminal M

SC-00160

( A )

( B )

(A) Pinion

(B) Gap

(C) Stopper

SC-00027

( A )

( B )

( C )