Subaru Legacy III (2000-2003 year). Manual - part 223

EN(H4SOw/oOBD)-82

ENGINE (DIAGNOSTICS)

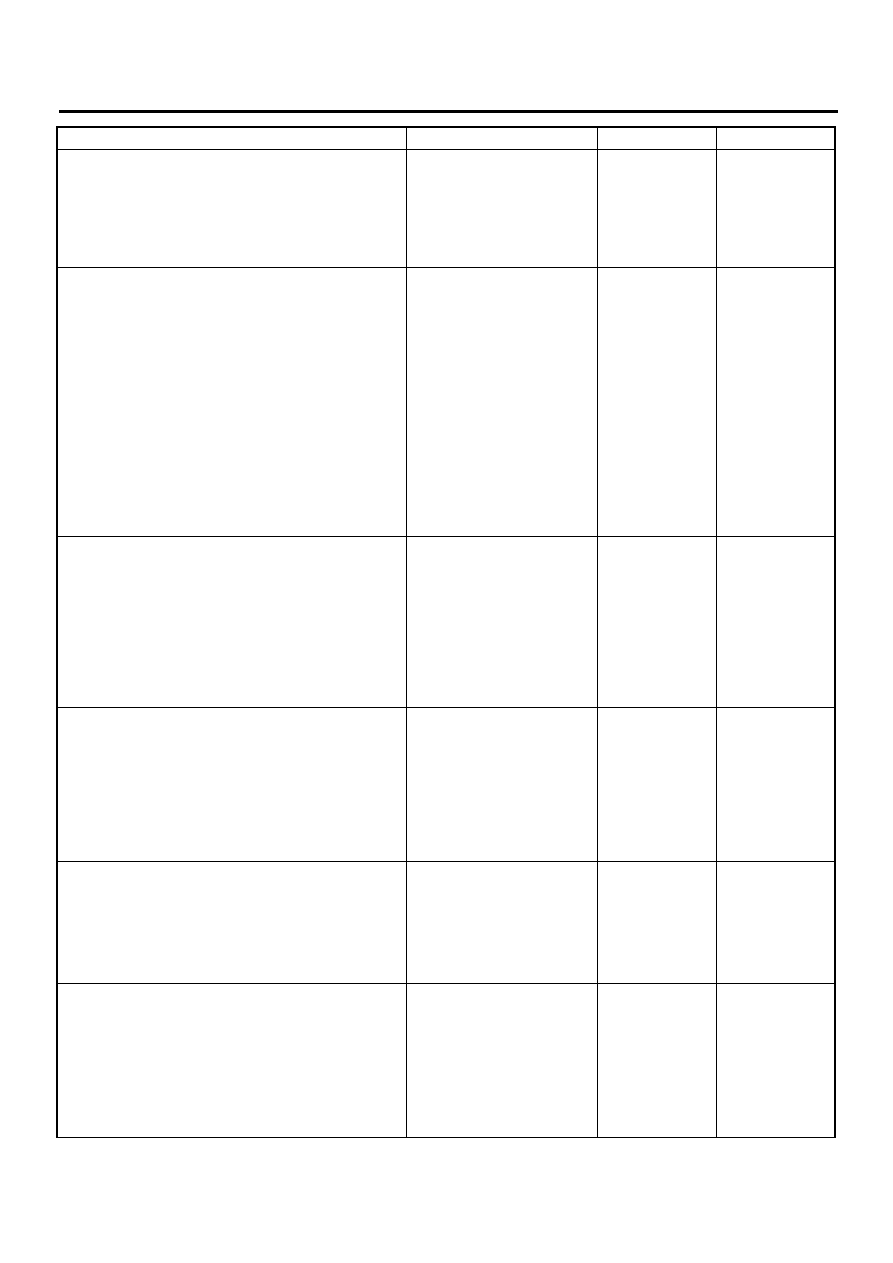

DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE (DTC)

Step

Value

Yes

No

1

CHECK FOR OTHER CAUSES AFFECTING

EXHAUST GAS.

1) Check for use of improper fuel.

2) Check if engine oil or coolant level is

extremely low.

Does CO% after warm-up exceed the spec-

ified value?

2%

Check fuel sys-

tem.

2

CHECK EXHAUST SYSTEM.

Is there a fault in exhaust system?

The system is faulty.

Repair exhaust

system.

NOTE:

• Loose installa-

tion of front portion

of exhaust pipe

onto cylinder

heads

• Loose connec-

tion between front

exhaust pipe and

front catalytic con-

verter

• Damage of

exhaust pipe

resulting in hole

3

CHECK INPUT VOLTAGE FOR OXYGEN

SENSOR.

1) Disconnect connector from oxygen sensor

connector.

2) Measure voltage between main relay and

oxygen sensor.

Connector & terminal

(B18) No. 2 (+) — Chassis ground (

−−−−

):

Does the measured value exceed the spec-

ified value?

10 V

Repair open circuit

between main

relay and oxygen

sensor.

4

CHECK HARNESS CONNECTOR BETWEEN

OXYGEN SENSOR AND ENGINE GROUND

TERMINAL.

Measure resistance between oxygen sensor

and chassis ground.

Connector & terminal

(B18) No. 1 — Chassis ground:

Is the measured value less than the specified

value?

1

Ω

Repair open circuit

between oxygen

sensor and chas-

sis ground.

5

CHECK OXYGEN SENSOR.

Measure resistance between oxygen sensor

terminals.

Connector & terminal

No. 1 — No. 2:

Is the measured value less than the specified

value?

30

Ω

Repair poor con-

tact.

6

CHECK HARNESS BETWEEN ECM AND OX-

YGEN SENSOR.

1) Disconnect connector from ECM.

2) Measure resistance between ECM and

chassis ground.

Connector & terminal

(B136) No. 7 — Chassis ground:

Does the measured value exceed the spec-

ified value?

1 M

Ω

Repair ground

short circuit

between ECM and

chassis ground.