Subaru Legacy III (2000-2003 year). Manual - part 162

EN(H4SO)-260

ENGINE (DIAGNOSTICS)

DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE (DTC)

6

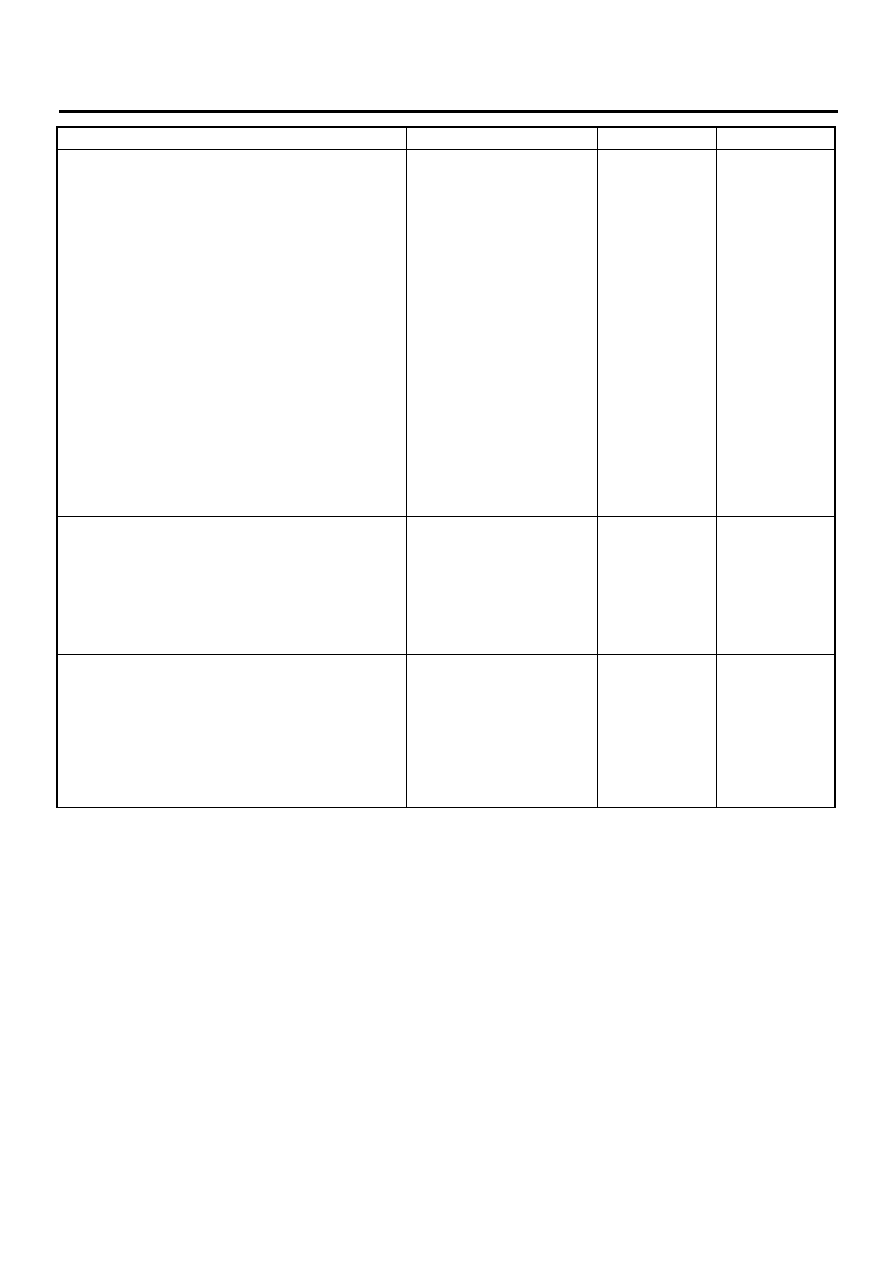

CHECK INHIBITOR SWITCH GROUND LINE.

Measure resistance of harness between inhibi-

tor switch connector and engine ground.

Connector & terminal

(T7) No. 12 — Engine ground:

Is the measured value less than the specified

value?

5

Ω

Repair open circuit

in harness

between inhibitor

switch connector

and starter motor

ground line.

NOTE:

In this case, repair

the following:

• Open circuit in

harness between

inhibitor switch

connector and

starter motor

grond line

• Poor contact in

satrter motor con-

nector

• Poor contact in

starter motor

ground

• Starter motor

7

CHECK INHIBITOR SWITCH.

Measure resistance between inhibitor switch

connector receptacle’s terminals in select level

“N” and “P” positions.

Terminal

No. 7 — No. 12:

Is the measured value less than the specified

value?

1

Ω

Replace inhibitor

switch. <Ref. to

AT-49, Inhibitor

Switch.>

8

CHECK SELECTOR CABLE CONNECTION.

Is there any fault in selector cable connection

to inhibitor switch?

There is a fault.

Repair selector

cable connection.

<Ref. to CS-12,

Select Cable.>

Contact SUBARU

distributor service.

NOTE:

Inspection by DTM

is required, be-

cause probable

cause is deteriora-

tion of multiple

parts.

Step

Value

Yes

No