Subaru Legacy III (2000-2003 year). Manual - part 130

EN(H4SO)-132

ENGINE (DIAGNOSTICS)

DIAGNOSTIC PROCEDURE WITH DIAGNOSTIC TROUBLE CODE (DTC)

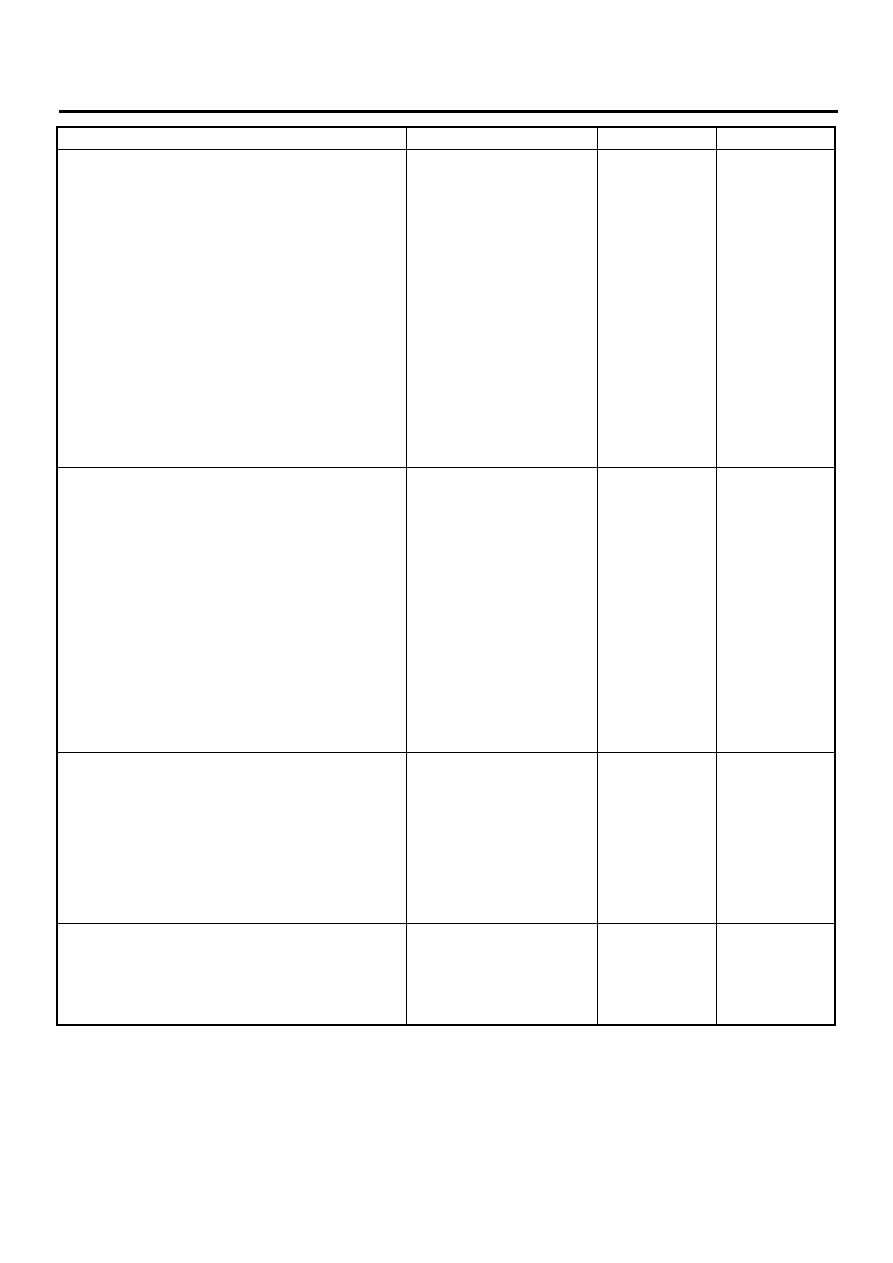

6

CHECK HARNESS BETWEEN ECM AND

THROTTLE POSITION SENSOR CONNEC-

TOR.

1) Turn ignition switch to OFF.

2) Disconnect connectors from throttle posi-

tion sensor.

3) Turn ignition switch to ON.

4) Measure voltage between throttle position

sensor connector and engine ground.

Connector & terminal

(E13) No. 4 (+) — Engine ground (

−−−−

):

Does the measured value exceed the spec-

ified value?

4.5 V

Repair harness

and connector.

NOTE:

In this case, repair

the following:

• Open circuit in

harness between

throttle position

sensor and ECM

connector

• Poor contact in

throttle position

sensor connector

• Poor contact in

ECM connector

• Poor contact in

coupling connector

• Poor contact in

joint connector

7

CHECK HARNESS BETWEEN ECM AND

THROTTLE POSITION SENSOR CONNEC-

TOR.

1) Turn ignition switch to OFF.

2) Measure resistance of harness between

ECM connector and throttle position sensor

connector.

Connector & terminal

(B135) No. 13 — (E13) No. 3:

Is the measured value less than the speci-

fied value?

1

Ω

Repair harness

and connector.

NOTE:

In this case, repair

the following:

• Open circuit in

harness between

throttle position

sensor and ECM

connector

• Poor contact in

ECM connector

• Poor contact in

throttle position

sensor connector

• Poor contact in

coupling connector

8

CHECK HARNESS BETWEEN ECM AND

THROTTLE POSITION SENSOR CONNEC-

TOR.

Measure resistance of harness between throt-

tle position sensor connector and engine

ground.

Connector & terminal

(E13) No. 3 — Engine ground:

Does the measured value exceed the specified

value?

1 M

Ω

Repair ground

short circuit in har-

ness between

throttle position

sensor and ECM

connector.

9

CHECK POOR CONTACT.

Check poor contact in throttle position sensor

connector.

Is there poor contact in throttle position sensor

connector?

There is poor contact.

Repair poor con-

tact in throttle posi-

tion sensor

connector.

Replace throttle

position sensor.

<Ref. to

FU(H4SO)-30,

Throttle Position

Sensor.>

Step

Value

Yes

No