Subaru Legacy III (2000-2003 year). Manual - part 23

PM-42

PERIODIC MAINTENANCE SERVICES

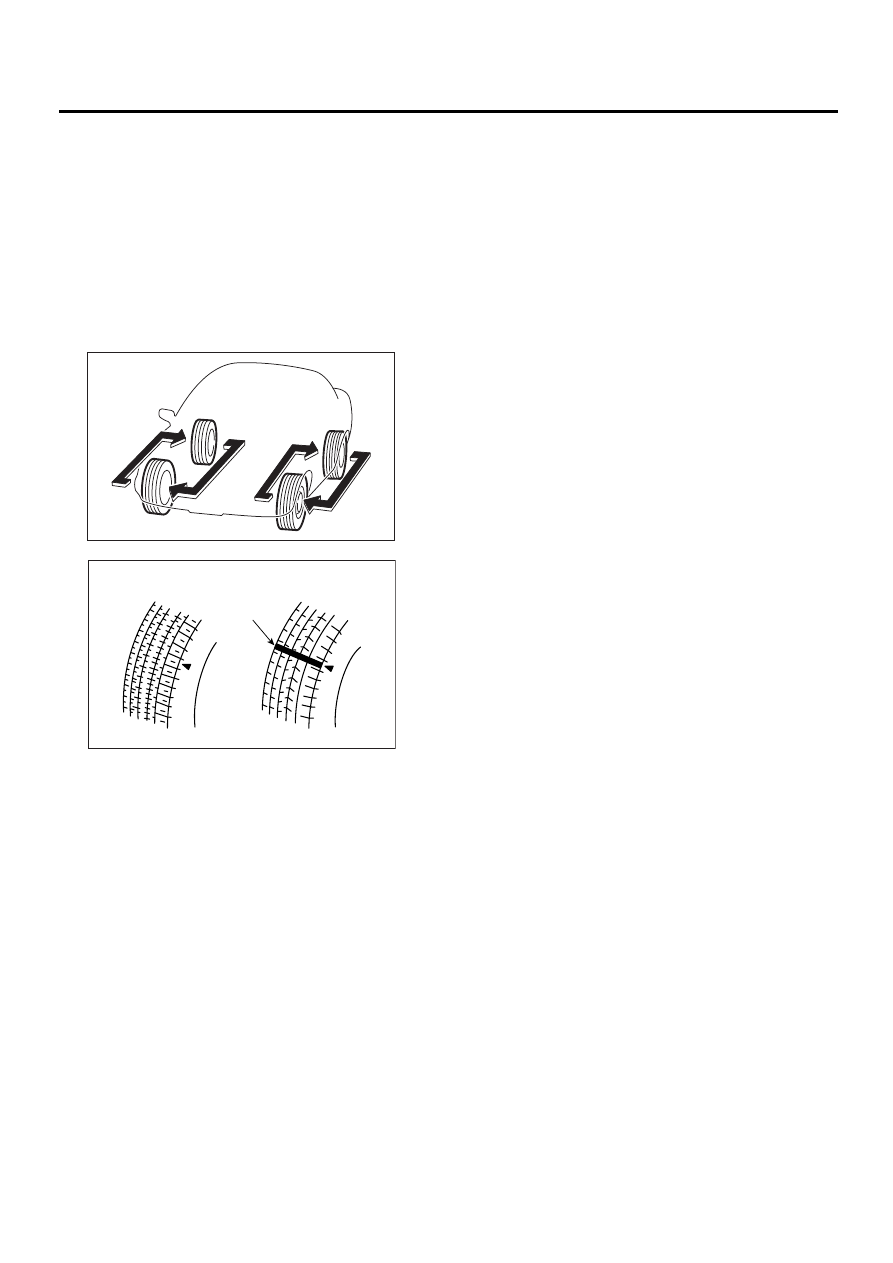

TIRE ROTATION

26.Tire Rotation

A: INSPECTION

1) Replace the tire if the tread depth is less than 1.6

mm (0.063 in) or if wear indicators appear across

the tire tread. (It is recommended that both right

and left tires are replaced as a set.)

2) Adjust the wheel alignment if abnormally uneven

tire wear is found.

3) Also, rotate the tires between the front and rear

tires as illustrated, in order to ensure uniform tire

wear.

(A) New tread

(B) Worn tread

(C) Tread wear indicator

PM-00079

PM-00080

(A)

(B)

(C)