Subaru Legacy III (2000-2003 year). Manual - part 12

PI-10

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

26. STARTING CONDITION

Start the engine and check that the engine starts

smoothly. If any battery voltage problems are

found, recharge or replace the battery. If any ab-

normal noises are observed, immediately stop the

engine and check and repair the necessary compo-

nents.

27. EXHAUST SYSTEM

Listen to the exhaust noise to see if no abnormal

noises are observed.

28. INDICATOR LIGHT

Check that all the indicator lights are off.

29. CLOCK

Check the clock for normal operations and enough

accuracy.

30. RADIO

Check the radio for full functionality and normal

noise level. Also check the CD unit operations.

31. CIGARETTE LIGHTER

Check that the cigarette lighter operations.

32. LIGHTING SYSTEM

• Check the headlight operations.

• Check the brake light operations.

• Check the other lights for normal operations.

33. WINDOW WASHER

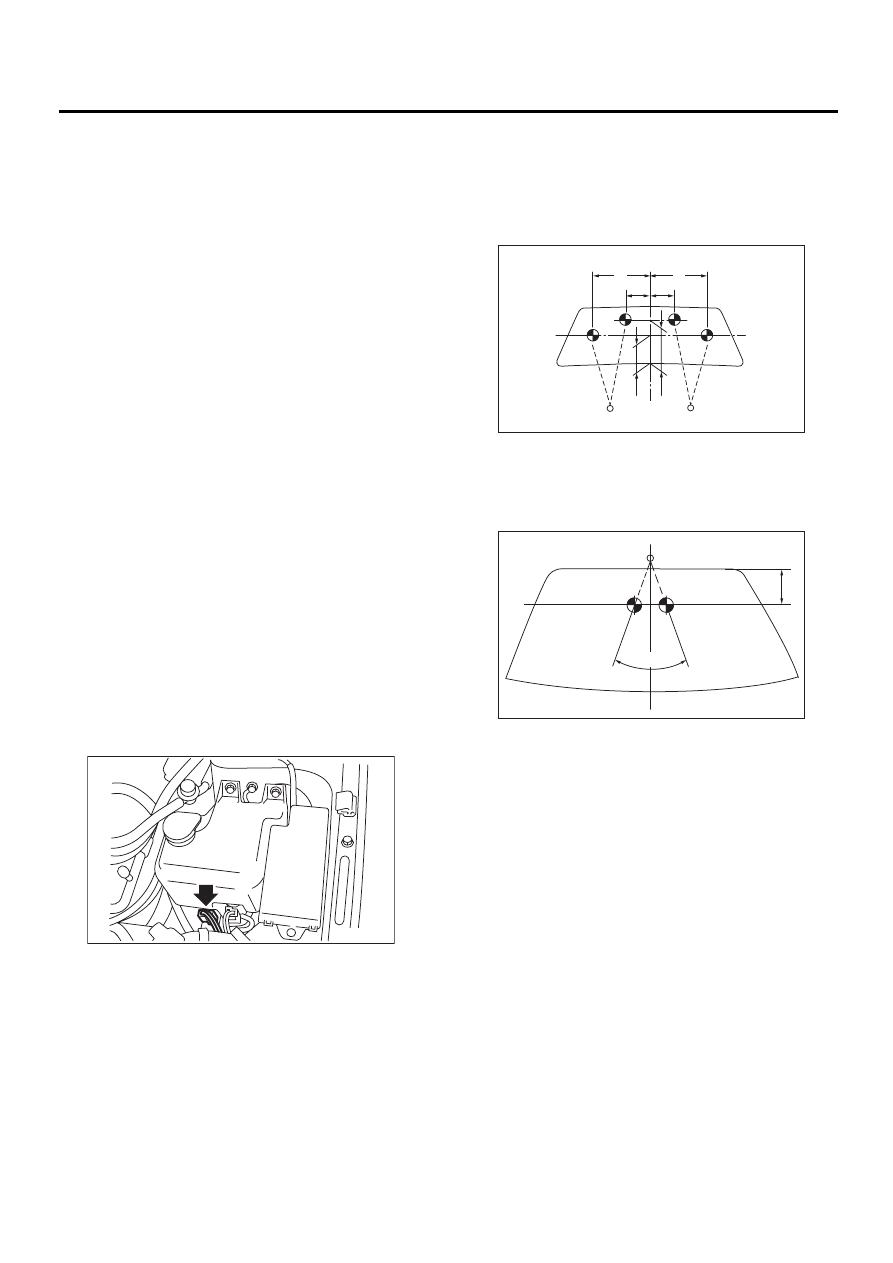

• Before inspection of the window washer system,

connect the washer connector to the washer motor.

• Check that the window washer system injects

washer fluid to the specified area of the windshield

shown in the figure.

NOTE:

If the washer fluid does not cover the specified ar-

ea, clean the nozzle.

Front

Injection position:

A: 350 mm (13.78 in)

B: 150 mm (5.91 in)

C: 300 mm (11.81 in)

D: 600 mm (23.62 in)

Rear

Injection position:

A: 60 mm (2.36 in)

B: 42

°°°°

34. WIPER

Check the front and rear wipers for normal opera-

tions.

35. POWER WINDOW OPERATION CHECK

Manipulate the power window switches one by one

to check that each of the power windows goes up

and down with no abnormal noises.

36. BRAKE TEST

Check the foot brake for normal operations.

37. PARKING BRAKE

Check the parking brake for normal operations.

PI-00102

PI-00121

A

B

C

D

B

A

PI-00104

A

B