Subaru Legacy (2005 year). Manual - part 855

PS-91

POWER ASSISTED SYSTEM (POWER STEERING)

Power Steering Fluid

11.Power Steering Fluid

A: SPECIFICATION

B: INSPECTION

1) Check the power steering fluid for deterioration

or contamination. If the fluid is highly deteriorated

or contaminated, drain it and refill with new fluid.

2) Check the joints and units for oil leakage. If any

oil leaks are found, repair or replace the applicable

part.

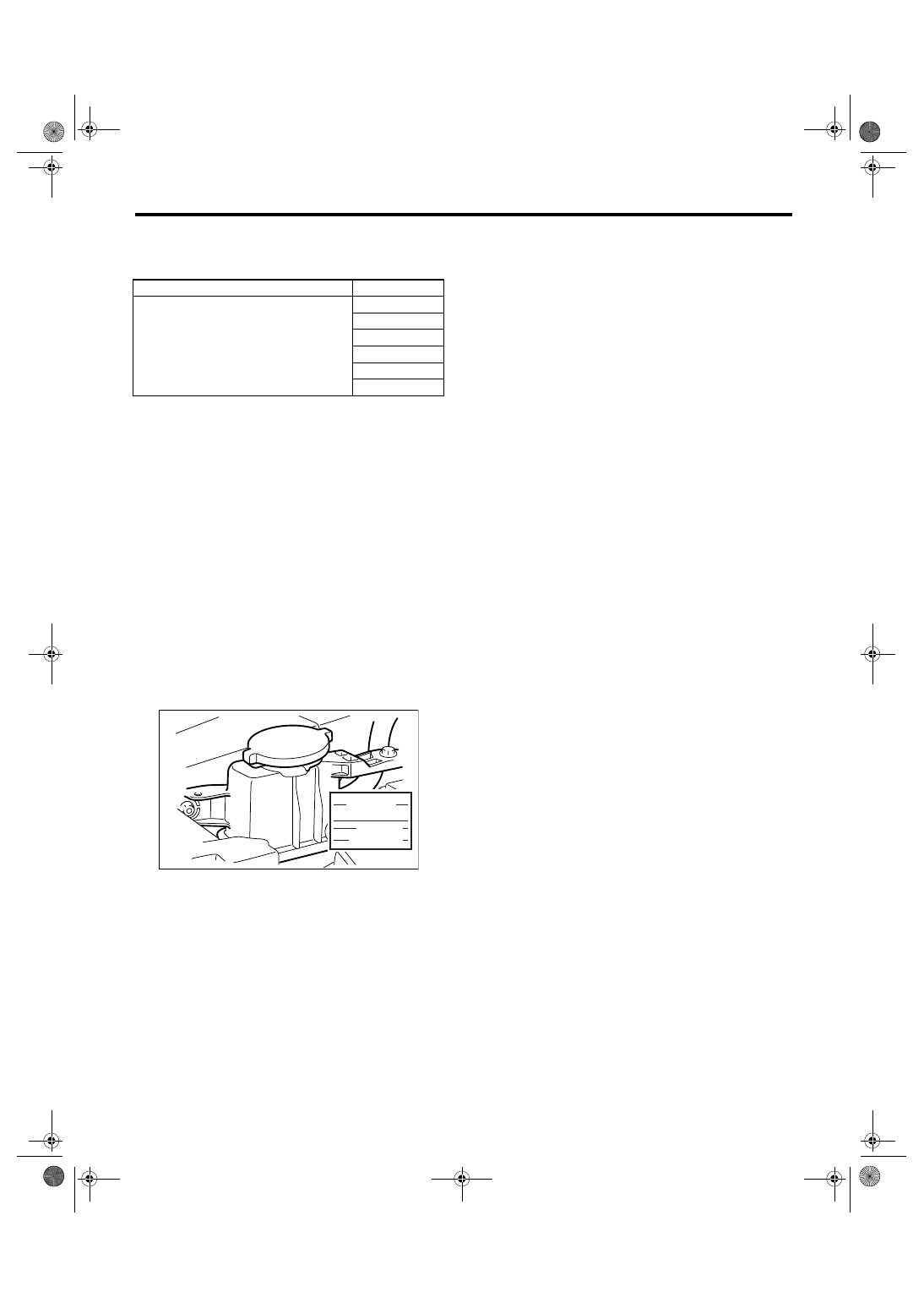

3) Inspect the fluid level on flat and level surface

with engine “OFF” by indicator of reservoir tank.

If the level is at “MIN.” point or below, add fluid to

keep the level in the specified range of the indica-

tor. If at “MAX.” point or above, drain fluid by using

a syringe or the like.

(1) Check at power steering fluid temperature

20

°C (68°F); read the fluid level on the “COLD”

side.

(2) Check at power steering fluid temperature

80

°C (176°F); read the fluid level on the “HOT”

side.

C: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the crossmember support.

3) Remove the pipe joint in the center of gearbox,

and connect the vinyl hose to the pipe and joint.

Wipe fluid off while turning the steering wheel.

4) Add the specified fluid to reservoir tank at MAX

level.

5) Continue to turn the steering wheel slowly from

lock to lock until the bubbles stop appearing on oil

surface while keeping the fluid at the level in the

Step 4).

6) If turning the steering wheel in low fluid level

condition, air will be sucked in pipe. In this case,

leave it about half an hour and then do the step 5)

again.

7) Start the engine and let it idle.

8) Continue to turn the steering wheel slowly from

lock to lock again until the bubbles stop appearing

on oil surface while keeping the fluid at the level in

Step 4).

Normally bubbles stop appearing after three times

turning of steering wheel from lock to lock.

9) In case bubbles do not stop appearing in the

tank, leave it about half an hour and then do the

step 4) all over again.

10) Lower the vehicle, and then idle the engine.

11) Continue to turn the steering wheel from lock to

lock until the bubbles stop appearing and change of

the fluid level is within 3 mm (0.12 in).

12) In case the following happens, leave it about

half an hour and then do step 8) to 11) again.

(1) The fluid level changes over 3 mm (0.12 in).

(2) Bubbles remain on the upper surface of the

fluid.

(3) Grinding noise is generated from oil pump.

13) Check the fluid leakage after turning steering

wheel from lock to lock with engine running.

Recommended power steering fluid

Manufacturer

ATF DEXRON III or equivalent

B.P.

CALTEX

CASTROL

MOBIL

SHELL

TEXACO

PS-00463

HOT MAX

COLD MAX

HOT MIN

COLD MIN