Subaru Legacy (2005 year). Manual - part 849

PS-67

POWER ASSISTED SYSTEM (POWER STEERING)

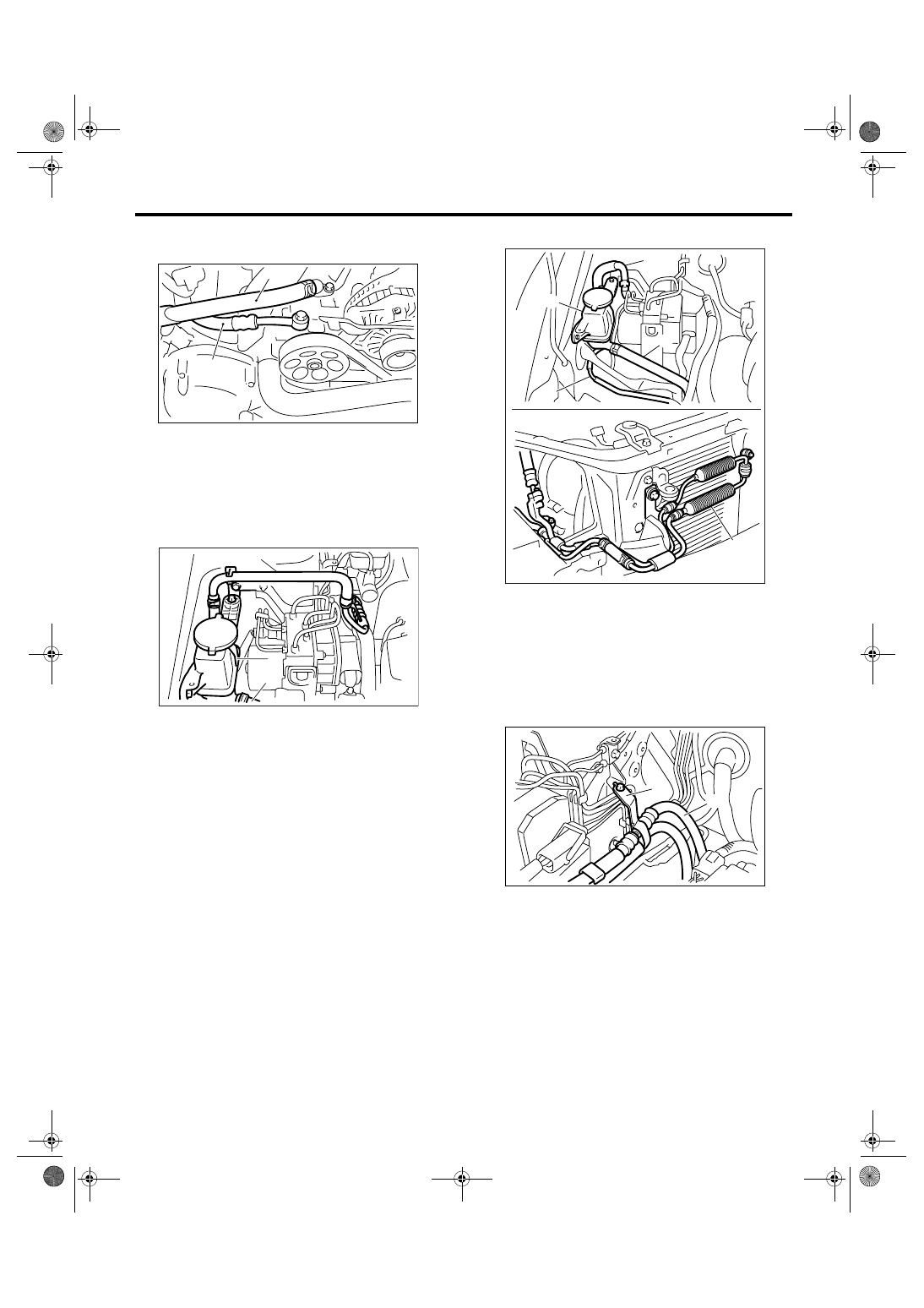

Pipe Assembly [LHD Model]

7) Disconnect the suction hose and pressure hose

from oil pump.

8) Disconnect the suction hose and return hose

from reservoir tank. Remove the oil cooler from oil

cooler bracket.

• H4 model

• H6 model

9) Remove the hose bracket and take out the hose

assembly from vehicle.

(1) Suction hose

(2) Pressure hose

(1) Reservoir tank

(2) Suction hose

(3) Return hose

PS-00688

(1)

(2)

PS-00697

(1)

(2)

(3)

(1) Reservoir tank

(2) Suction hose

(3) Return hose

(4) Oil cooler pipe

(5) Oil cooler

(1) Hose ASSY

(2) Hose bracket

(3)

(4)

(5)

PS-00623

(2)

(1)

PS-00624

(2)

(1)