Subaru Legacy (2005 year). Manual - part 826

BR-33

BRAKE

Brake Booster

9. Brake Booster

A: REMOVAL

1) Remove or disconnect the following parts at en-

gine compartment.

(1) Disconnect the connector for brake fluid lev-

el gauge.

(2) Remove the brake pipes from master cylin-

der.

(3) Remove the master cylinder installing nuts.

(4) Disconnect the vacuum hose from brake

booster.

2) Remove the following parts from pedal bracket.

(1) Snap pin and clevis pin

(2) Four brake booster installing nuts

3) Remove the brake booster while shunning brake

pipes.

NOTE:

• Do not apply strong impact to booster shell and

vacuum pipe.

• Be careful not to drop the brake booster. The

brake booster should be replaced if it has been

dropped.

• Use special care when handling the operating

rod. If excessive force is applied to operating rod,

sufficient to cause a change in the angle in excess

of

±3°, it may result in damage to the power piston

cylinder.

• Use care when placing the brake booster on the

floor.

• Do not change the push rod length.

CAUTION:

• Do not disassemble the brake booster.

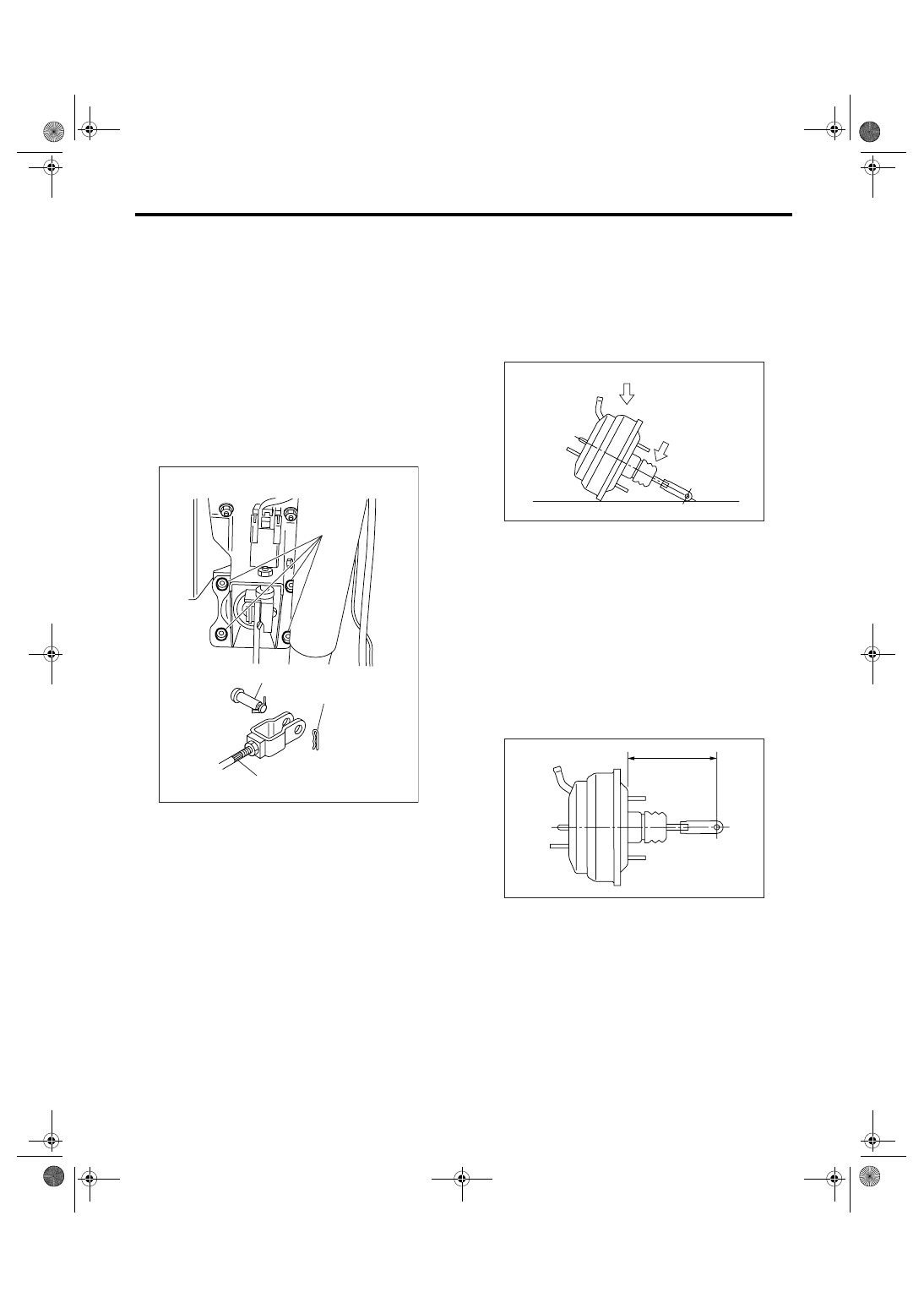

• If external force is applied from above when

brake booster is placed in this position, the res-

in portion as indicated by “P” may be damaged.

B: INSTALLATION

1) Check and adjust the operating rod of brake

booster.

Specification L:

LHD

136.3 mm (5.38 in)

RHD

155.2 mm (6.11 in)

If it is not within the specification, adjust it by the

brake booster operating rod.

2) Mount the brake booster in position.

(1) Nut

(2) Clevis pin

(3) Snap pin

(4) Operating rod

(1)

(3)

(4)

(2)

BR-00073

(1) Force

(1)

P

BR-00075

L

BR-00076