Subaru Legacy (2005 year). Manual - part 597

5AT-87

AUTOMATIC TRANSMISSION

Drive Pinion Shaft Assembly

33.Drive Pinion Shaft Assembly

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle. <Ref. to 5AT-38, REMOVAL, Automatic Trans-

mission Assembly.>

2) Pull out the torque converter assembly. <Ref. to

5AT-70, REMOVAL, Torque Converter Assembly.>

3) Remove the transmission harness connector

from stay.

4) Disconnect the air breather hose. <Ref. to 5AT-

68, REMOVAL, Air Breather Hose.>

5) Remove the oil charge pipe. <Ref. to 5AT-69,

REMOVAL, Oil Charge Pipe.>

6) Remove the ATF filter inlet and outlet pipes.

<Ref. to 5AT-60, REMOVAL, ATF Filter.>

7) Separate the converter case and transmission

case part. <Ref. to 5AT-82, REMOVAL, Converter

Case.>

8) Remove the drive pinion shaft mounting bolt,

and then remove the drive pinion shaft assembly

from oil pump cover.

9) Remove the oil pump cover from AT main case.

<Ref. to 5AT-84, REMOVAL, Oil Pump Cover.>

B: INSTALLATION

1) Assemble the drive pinion assembly to oil pump

cover.

NOTE:

Be careful not to bend the shim.

Tightening torque:

70 N

⋅

m (7.1 kgf-m, 51.6 ft-lb)

2) Adjust the tooth contact between drive pinion

shaft assembly and front differential side gear.

<Ref. to 5AT-89, ADJUSTMENT, Drive Pinion

Shaft Assembly.>

3) Combine the converter case with transmission

case. <Ref. to 5AT-82, INSTALLATION, Converter

Case.>

4) Install the transmission harness connector to the

stay.

5) Install the ATF filter pipe. <Ref. to 5AT-60, IN-

STALLATION, ATF Filter.>

6) Install the oil charge pipe with O-ring.

7) Install the torque converter assembly. <Ref. to

5AT-70, INSTALLATION, Torque Converter As-

sembly.>

8) Install the transmission assembly into vehicle.

<Ref. to 5AT-42, INSTALLATION, Automatic

Transmission Assembly.>

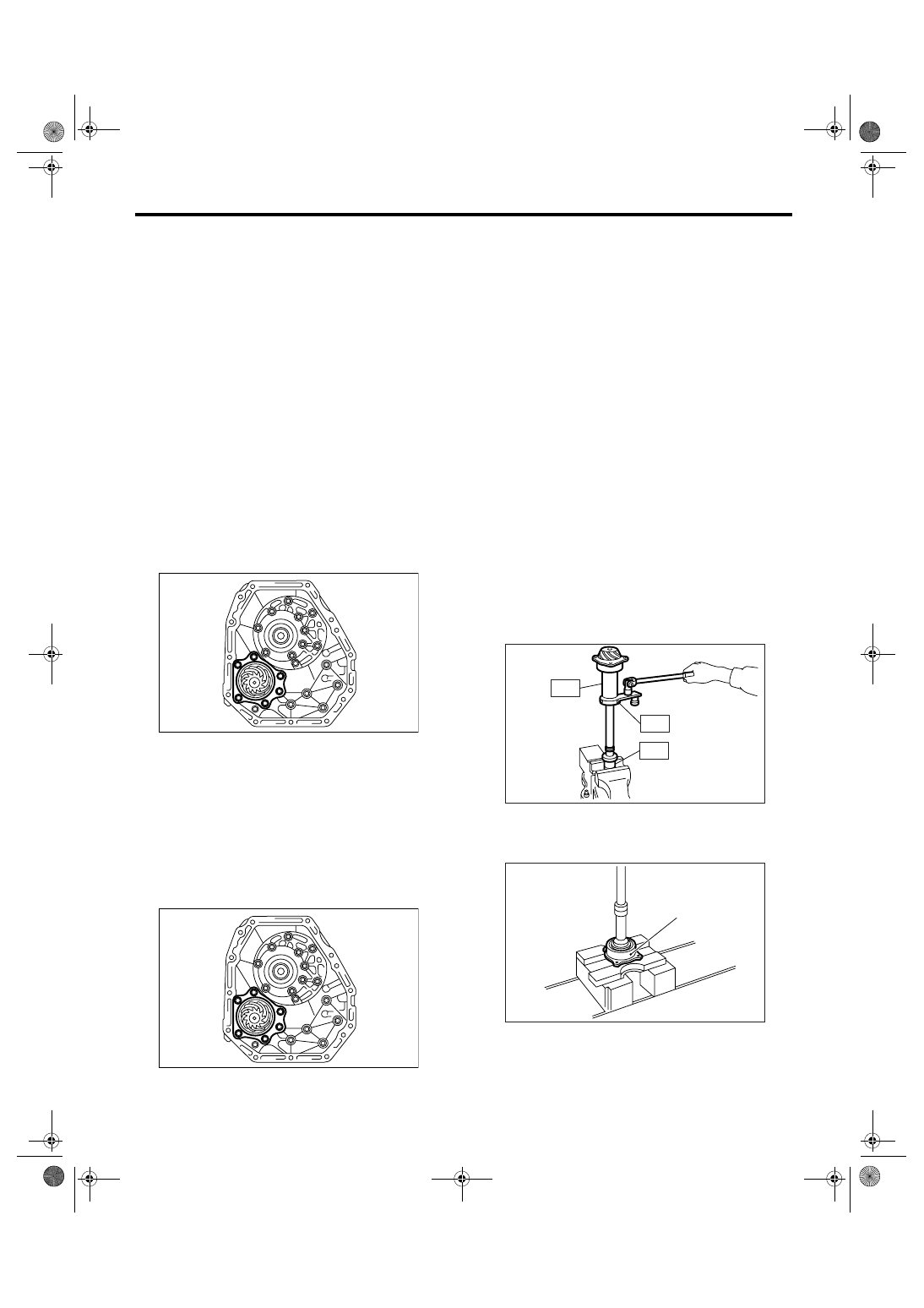

C: DISASSEMBLY

1) Remove the caulking part of lock nut, and then

remove the lock nut with holding rear spline part of

the shaft using ST1 and ST2. Pull out the drive pin-

ion collar.

ST1

18667AA010 HOLDER

ST2

499787700

WRENCH

ST3

499787500

ADAPTER

2) Remove the O-ring.

3) Separate the rear roller bearing and outer race

(A) from shaft using press.

4) Separate the front roller bearing (A) from shaft

using press and ST.

AT-01984

AT-01984

AT-00197

ST1

ST3

ST2

AT-00198

(A)