Subaru Legacy (2005 year). Manual - part 477

EN(H6DO)(diag)-221

ENGINE (DIAGNOSTICS)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

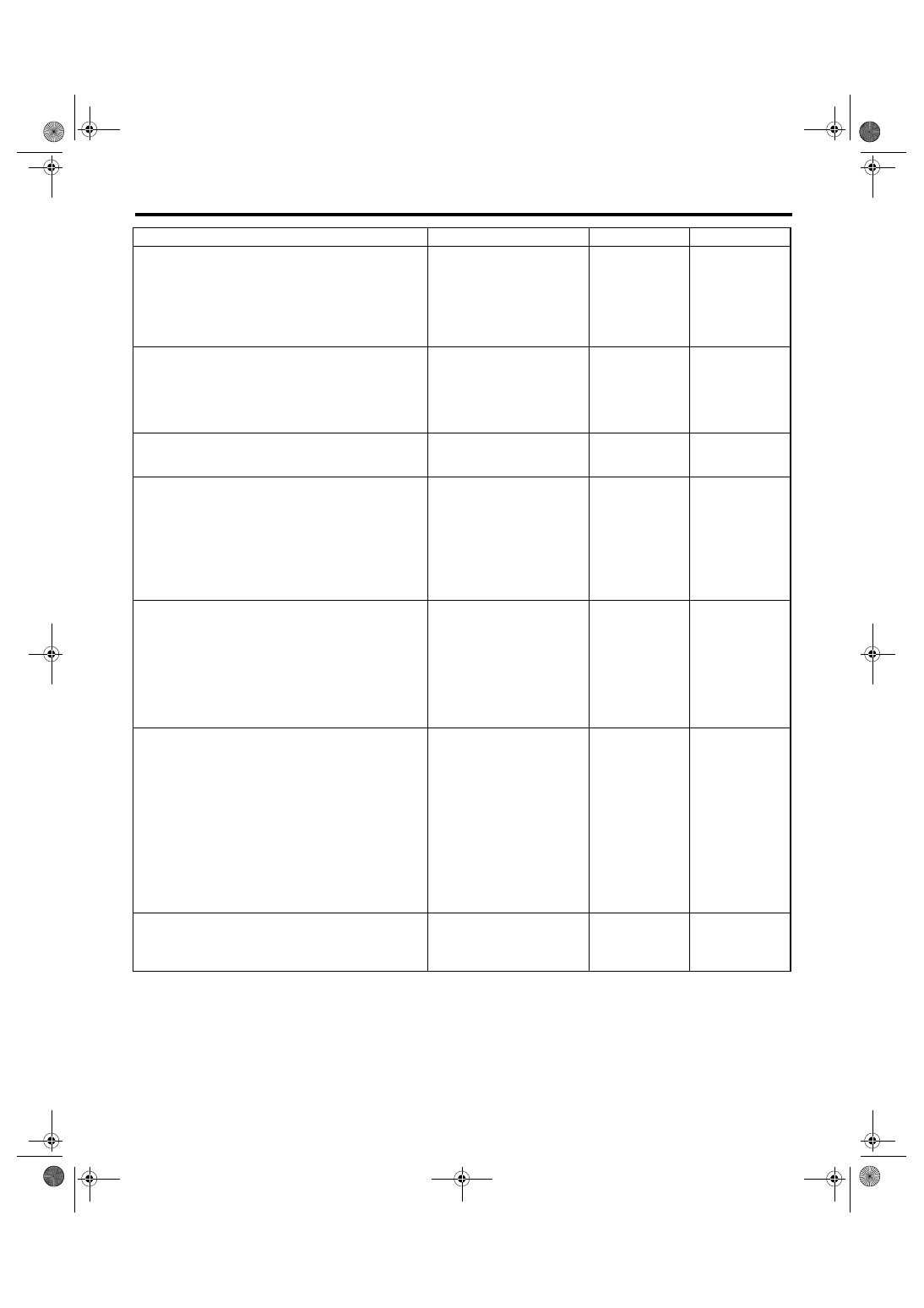

Step

Check

Yes

No

1

CHECK INPUT SIGNAL OF ECM.

1) Turn the ignition switch to ON.

2) Place the shift lever except in neutral.

3) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B137) No. 9 (+) — Chassis ground (

−

):

Is the voltage more than 10 V? Go to step 2.

2

CHECK INPUT SIGNAL OF ECM.

1) Place the shift lever in neutral.

2) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B137) No. 9 (+) — Chassis ground (

−

):

Is the voltage less than 1 V?

3

CHECK POOR CONTACT.

Check poor contact in ECM connector.

Is there poor contact in ECM

connector?

Repair the poor

contact in ECM

connector.

Replace the ECM.

4

CHECK NEUTRAL POSITION SWITCH.

1) Place the shift lever in neutral.

2) Measure the resistance between transmis-

sion harness connector terminals.

Connector & terminal

LHD model

(T2) No. 1 — No. 3:

LHD model

(T9) No. 1 — No. 3:

Is the resistance less than 1

Ω?

Repair the open

circuit in transmis-

sion harness or

replace the neu-

tral position switch.

5

CHECK HARNESS BETWEEN ECM AND

NEUTRAL POSITION SWITCH CONNEC-

TOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between ECM and transmission harness con-

nector.

Connector & terminal

(B137) No. 9 — (B128) No. 1:

Is the resistance less than 1

Ω?

Repair the open

circuit of harness

between ECM and

transmission har-

ness connector.

6

CHECK HARNESS BETWEEN ECM AND

NEUTRAL POSITION SWITCH CONNEC-

TOR.

Measure the resistance of harness between

transmission harness connector and engine

ground.

Connector & terminal

(B128) No. 3 — Engine ground:

Is the resistance less than 5

Ω?

Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following:

• Open circuit of

harness between

transmission har-

ness connector

and engine ground

• Poor contact in

coupling connector

7

CHECK POOR CONTACT.

Check poor contact in transmission harness

connector.

Is there poor contact in trans-

mission harness connector?

Repair poor con-

tact in transmis-

sion harness

connector.

Replace the ECM.