Subaru Legacy (2005 year). Manual - part 397

ME(H6DO)-63

MECHANICAL

Cylinder Head

(3) Turn the cylinder head upside down and

place the ST as shown in the figure.

ST

18251AA040

VALVE GUIDE ADJUSTER

(4) Before installing a new valve guide, make

sure that neither scratches nor damages exist

on the inside surface of the valve guide holes in

cylinder head.

(5) Put a new valve guide, coated with sufficient

oil, in cylinder, and insert the ST1 into valve

guide. Press in until the valve guide upper end is

flush with the upper surface of ST2.

ST1

499765700

VALVE GUIDE REMOVER

ST2

18251AA040 VALVE GUIDE ADJUSTER

(6) Check the valve guide protrusion.

Valve guide protrusion L:

11.4 — 11.8 mm (0.449 — 0.465 in)

(7) Ream the inside of valve guide using ST.

Put the reamer in valve guide, and rotate the

reamer slowly clockwise while pushing it lightly.

Bring the reamer back while rotating it clock-

wise. After reaming, clean the valve guide to re-

move chips.

ST

499765900

VALVE GUIDE REAMER

NOTE:

• Apply engine oil to the reamer when reaming.

• If the inner surface of the valve guide is torn, the

edge of the reamer should be slightly ground with

an oil stone.

• If the inner surface of the valve guide becomes

lustrous and the reamer does not chip, use a new

reamer or remedy the reamer.

(8) Recheck the contact condition between

valve and valve seat after replacing the valve

guide.

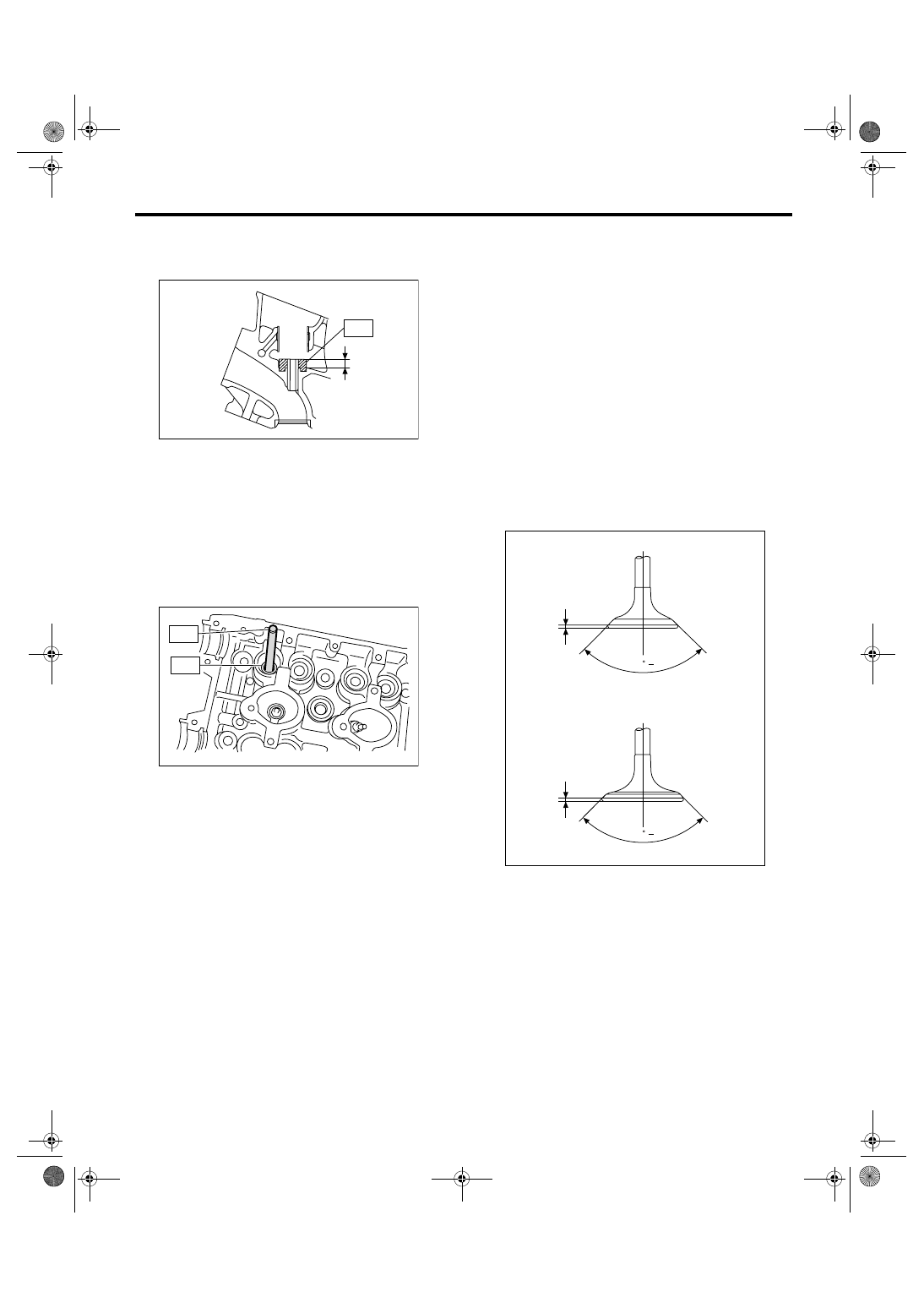

4. INTAKE AND EXHAUST VALVE

1) Inspect the flange and stem of valve, and re-

place if damaged, worn or deformed, or if “H” ex-

ceeds the standard or offset wearing is emitted.

H:

Intake (A)

Standard: 1.0 mm (0.039 in)

Exhaust (B)

Standard: 1.2 mm (0.047 in)

Valve overall length:

Intake (A)

99.7 mm (3.925 in)

Exhaust (B)

105.2 mm (4.142 in)

2) Put a small amount of grinding compound on the

seat surface, and lap the valve and seat surface.

Install a new intake valve oil seal after lapping.

ME-00757

ST

L

ME-00130

ST1

ST2

ME-02096

H

H

(B)

(A)

90 0

+1

90 0

+1