Subaru Legacy (2005 year). Manual - part 281

ME(H4DOTC)-67

MECHANICAL

Cylinder Head

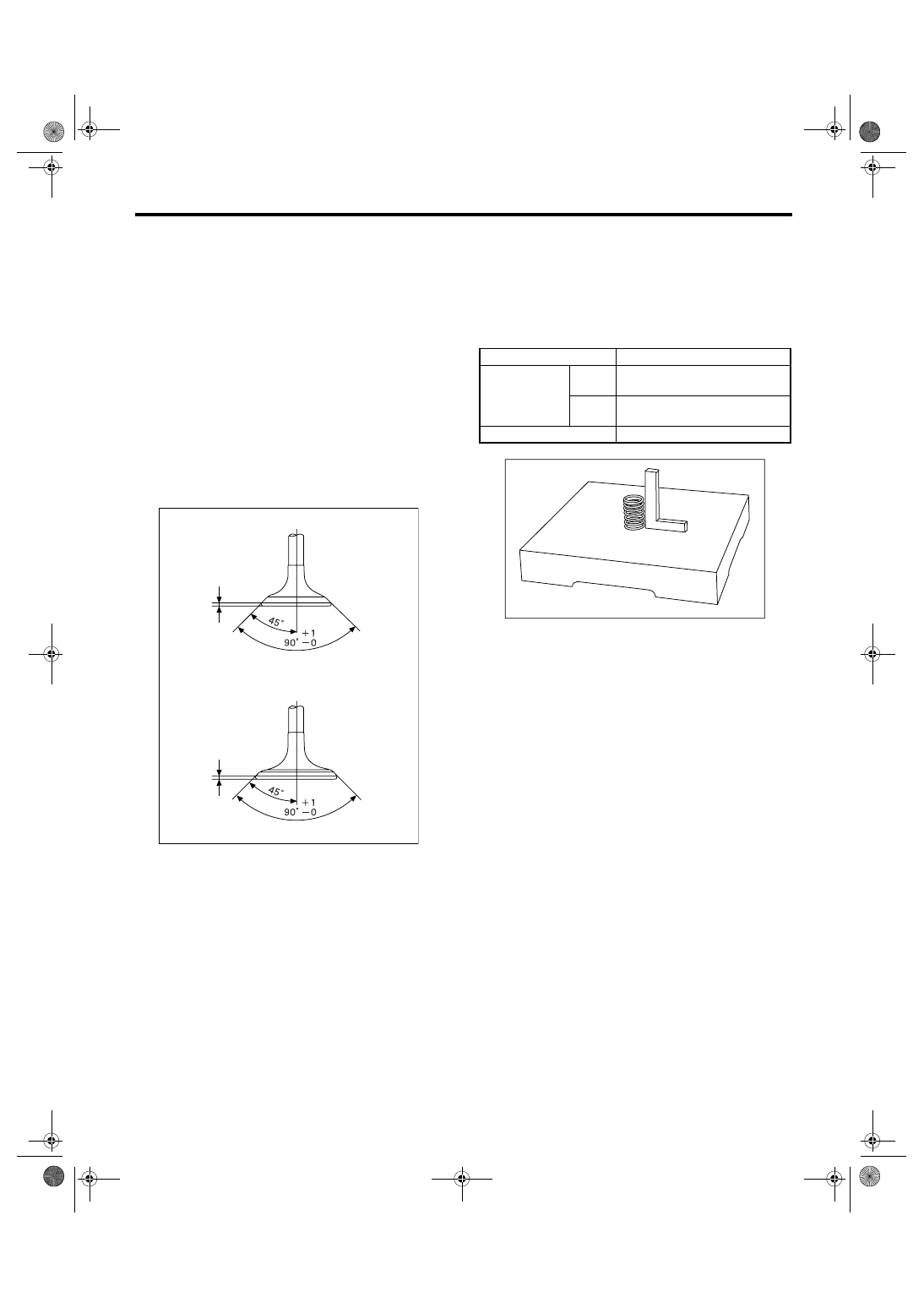

4. INTAKE AND EXHAUST VALVE

1) Inspect the flange and stem of valve, and re-

place if damaged, worn or deformed, or if “H” ex-

ceeds the standard or offset wear occurs.

Head edge thickness H:

Intake (A)

Standard

1.0 — 1.4 mm (0.039 — 0.055 in)

Exhaust (B)

Standard

1.3 — 1.7 mm (0.051 — 0.067 in)

Valve overall length:

Intake (A)

104.4 mm (4.110 in)

Exhaust (B)

104.65 mm (4.1201 in)

2) Put a small amount of grinding compound on the

seat surface and lap the valve and seat surface. In-

stall a new intake valve oil seal after lapping.

5. VALVE SPRING

1) Check the valve springs for damage, free length,

and tension. Replace the valve spring if it is not

within the standard presented in the table.

2) To measure the squareness of the valve spring,

stand the spring on a surface plate and measure its

deflection at the top of spring using a try square.

ME-00758

H

H

(B)

(A)

Free length

mm (in) 44.67 (1.759)

Tension/spring

height

Set

206 — 236 (21.0 — 24.1, 46.3 —

53.1)/36.0 (1.417)

N (kgf, lbf)/mm

(in)

Lift

485 — 537 (21.0 — 24.1, 109 —

121)/26.6 (1.047)

Squareness

2.5

°, 2.0 mm (0.079 in)

ME-00132