Subaru Legacy (2005 year). Manual - part 278

ME(H4DOTC)-55

MECHANICAL

Crank Sprocket

18.Crank Sprocket

A: REMOVAL

1) Remove the V-belts. <Ref. to ME(H4DOTC)-40,

REMOVAL, V-belt.>

2) Remove the crank pulley.

<Ref. to ME(H4DOTC)-43, REMOVAL, Crank Pul-

ley.>

3) Remove the timing belt cover.

<Ref. to ME(H4DOTC)-45, REMOVAL, Timing Belt

Cover.>

4) Remove the timing belt.

<Ref. to ME(H4DOTC)-46, REMOVAL, Timing

Belt.>

5) Remove the cam sprocket.

<Ref. to ME(H4DOTC)-54, REMOVAL, Cam

Sprocket.>

6) Remove the crank sprocket.

B: INSTALLATION

1) Install the crank sprocket.

2) Install the cam sprocket.

<Ref. to ME(H4DOTC)-54, INSTALLATION, Cam

Sprocket.>

3) Install the timing belt.

<Ref. to ME(H4DOTC)-48, INSTALLATION, Tim-

ing Belt.>

4) Install the timing belt cover.

<Ref. to ME(H4DOTC)-45, INSTALLATION, Tim-

ing Belt Cover.>

5) Install the crank pulley. <Ref. to ME(H4DOTC)-

43, INSTALLATION, Crank Pulley.>

6) Install the V-belts. <Ref. to ME(H4DOTC)-40,

INSTALLATION, V-belt.>

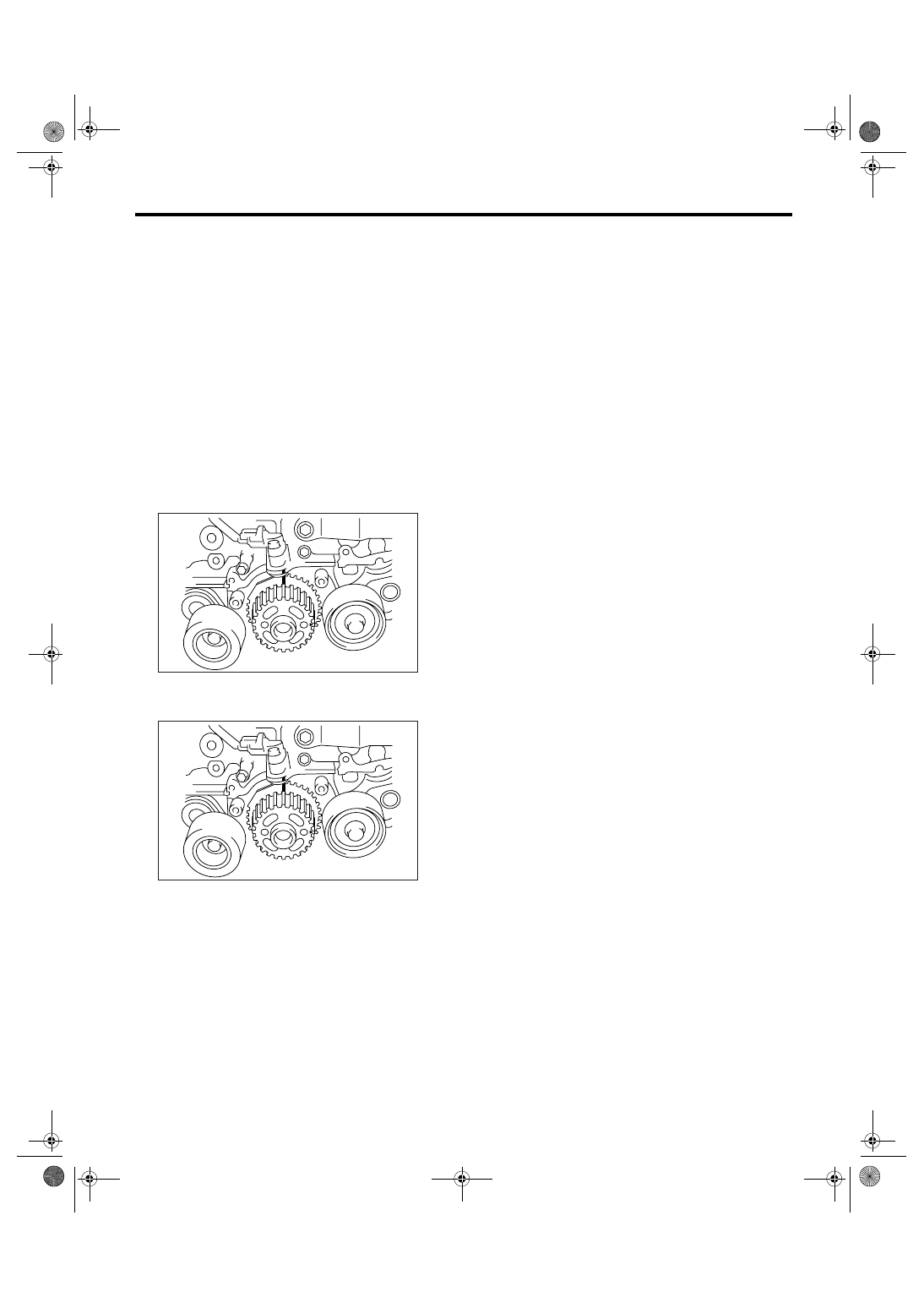

C: INSPECTION

1) Check the crank sprocket teeth for abnormal

wear and scratches.

2) Make sure there is no free play between crank

sprocket and key.

3) Check the crank sprocket protrusion used for

sensor for damage and contamination of foreign

matter.

ME-00103

ME-00103