Subaru Legacy (2005 year). Manual - part 117

EN(H4SO 2.0)(diag)-57

ENGINE (DIAGNOSTICS)

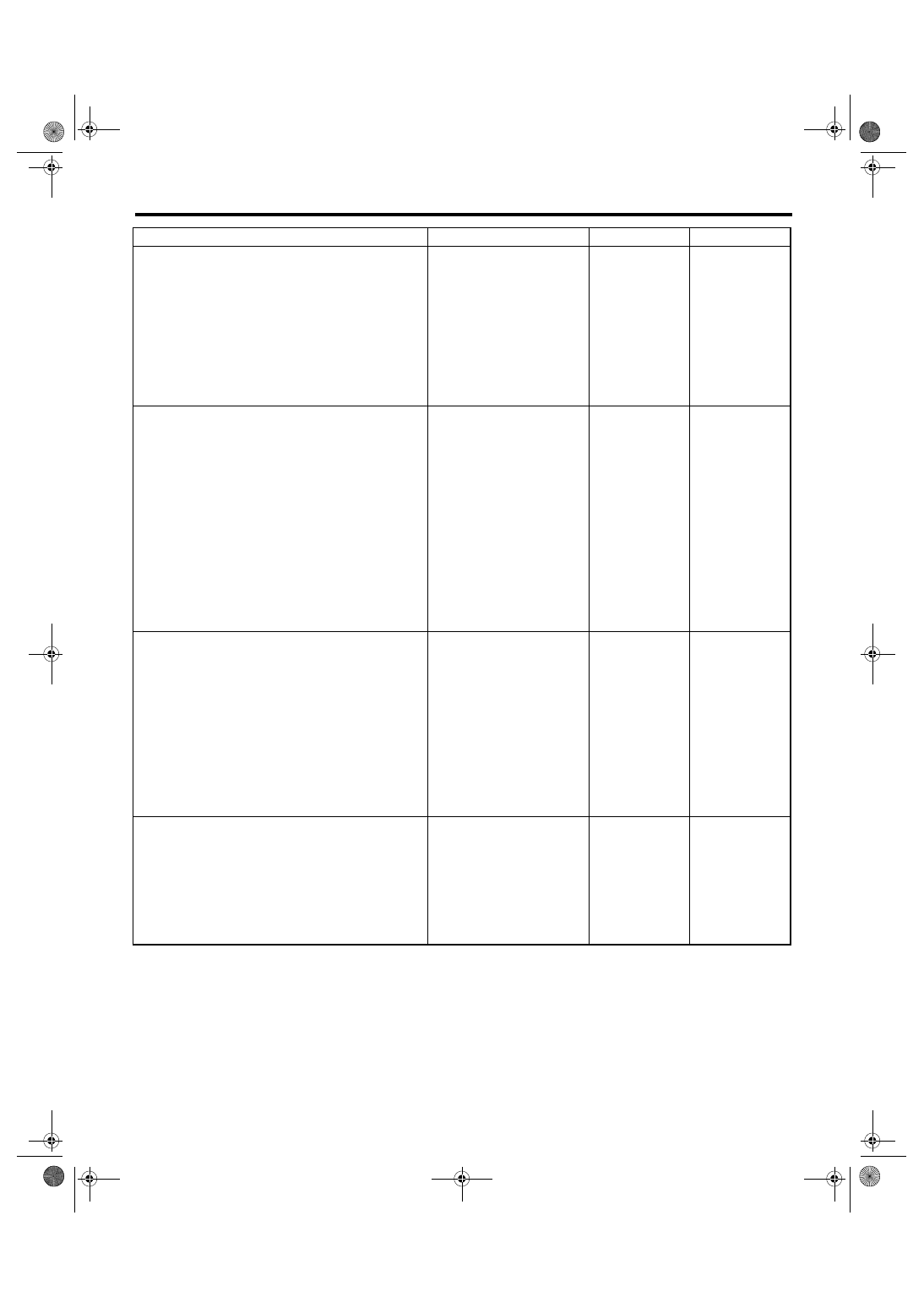

Diagnostics for Engine Starting Failure

Step

Check

Yes

No

1

CHECK IGNITION SYSTEM FOR SPARKS.

1) Remove the plug cord cap from each spark

plug.

2) Install a new spark plug on plug cord cap.

CAUTION:

Do not remove the spark plug from engine.

3) Contact the spark plug thread portion on

engine.

4) While opening the throttle valve fully, crank

the engine to check that spark occurs at each

cylinder.

Does spark occur at each cyl-

inder?

Check the fuel

pump system.

<Ref. to EN(H4SO

2.0)(diag)-59,

FUEL PUMP CIR-

CUIT, Diagnostics

for Engine Start-

ing Failure.>

2

CHECK POWER SUPPLY CIRCUIT FOR IG-

NITION COIL AND IGNITOR ASSEMBLY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ignition coil

and ignitor assembly.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between

ignition coil and ignitor assembly connector

and engine ground.

Connector & terminal

2.0 L model

(E12) No. 1 (+) — Engine ground (

−

):

2.5 L LHD model

(E12) No. 2 (+) — Engine ground (

−

):

2.5 L RHD model

(E12) No. 4 (+) — Engine ground (

−

):

Is the voltage more than 10 V? Go to step 3.

Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

• Open circuit of

harness between

ignition coil and

ignitor assembly,

and main relay

connector

• Poor contact in

coupling connector

• Blown out fuse

3

CHECK HARNESS OF IGNITION COIL AND

IGNITOR ASSEMBLY GROUND CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between ignition

coil and ignitor assembly connector and engine

ground.

Connector & terminal

2.0 L model and 2.5 L LHD model

(E12) No. 3 — Engine ground:

2.5 L RHD model

(E12) No. 2 — Engine ground:

Is the resistance less than 5

Ω?

Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

• Open circuit of

harness between

ignition coil and

ignitor assembly

connector and

engine grounding

terminal

4

CHECK IGNITION COIL AND IGNITOR AS-

SEMBLY.

1) Remove the spark plug cords.

2) Measure the resistance between spark

plug cord contact portions to check secondary

coil.

Terminals

No. 1 — No. 2:

No. 3 — No. 4:

Is the resistance 10 — 15 k

Replace the igni-

tion coil and ignitor

assembly. <Ref. to

IG(H4SO 2.0)-8,

Ignition Coil and

Ignitor Assembly.>