SsangYong Rexton. Manual - part 627

SSANGYONG Y200

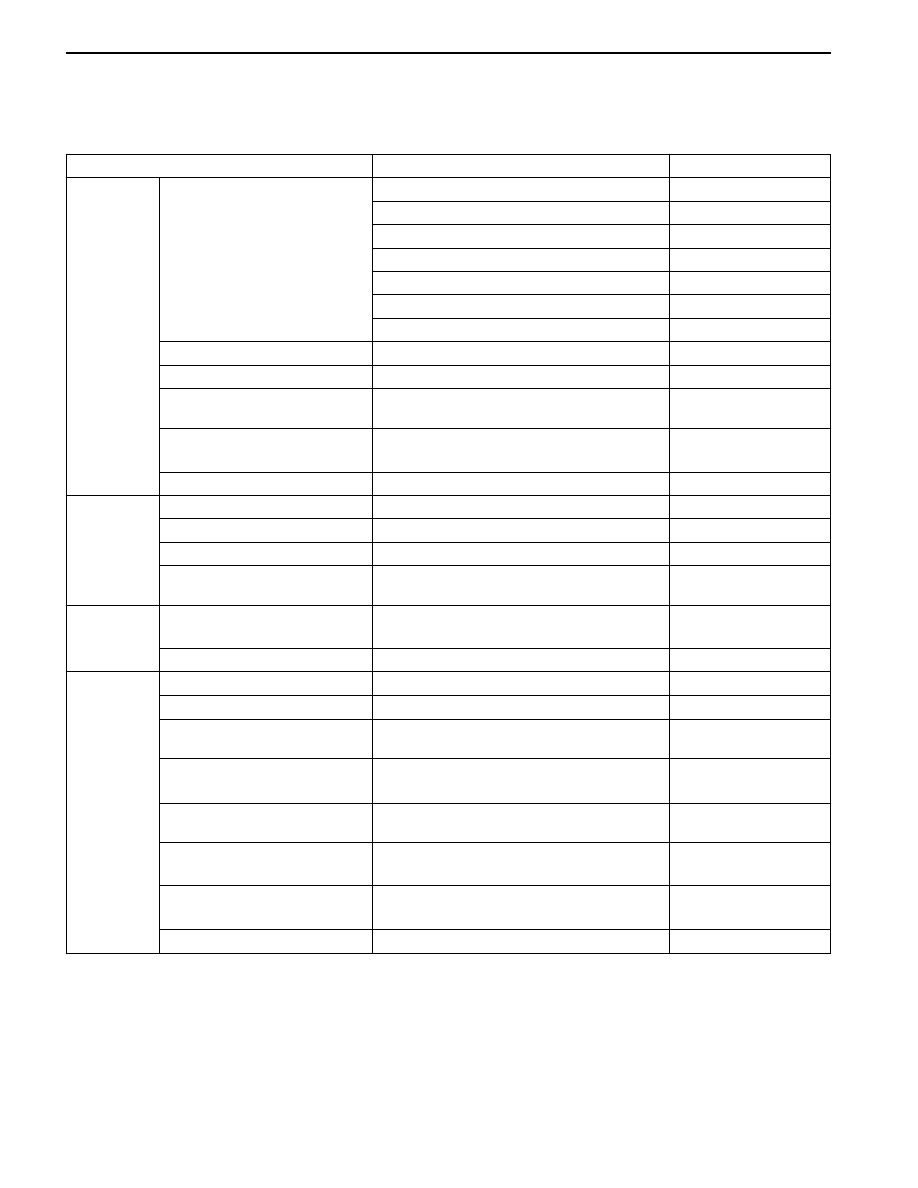

7B-10 GENERAL HVAC SYSTEM

DIAGNOSTIC INFORMATION AND PROCEDURES

GENERAL DIAGNOSIS

Check the fuse

Check the A/C switch

Check the triple switch (DSL: Dual switch)

Check the thermo switch (GSL)

Check the compressor relay

Check the magnetic clutch

Check the A/C control unit

Check the refrigerant capacity

Check the receiver-drier

Check the drive belt’s tension, slip of the

compressor and clutch

Check the compressor

Check the expansion valve

Check the Duct joint

Check the intake air temperature switch

Check the blower motor

Check the resistor, connector

Measure the pressure

Check the expansion valve

Check the refrigerant capacity

Check the receiver-drier

Check the fin’s surface and crack of the

tube, tank

Check the refrigerant capacity (Verify the

capacity higher than high pressure)

Check the drive belt’s tension

Check the compressor

Check the pressure

Check the expansion valve

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adding refrigerant

Replace

Adjusting belt

Replace

Replace

Replace

Replace

Replace

Replace

Evacuating and

charging refrigerant

Replace

Adding refrigerant

Replace

Cleaning surface,

Replace

Recharging

refrigerant

Adjusting belt

Replace

Evacuating and

charging refrigerant

Replace

Check

Symptom

Magnetic clutch switch don’t

turn ON.

Insufficient refrigerant

Faulty receiver-drier

Abnormal rotating of

compressor

Abnormal compression of

compressor

Faulty expansion valve

Duct joint leak

Evaporator frozen

Faulty blower motor

Blower 1th - 3th inoperative,

4th operative

There is air in the refrigerant

Faulty expansion valve

Insufficient refrigerant

Faulty receiver-drier

Faulty condenser

Excessive refrigerant in the

system

Abnormal rotating of com-

pressor

Insufficient compression of

compressor

There is air in the unit.

Faulty expansion valve

Airflow not

cold.

Action

Airflow is

cold but

insufficient.

Airflow is

not

continuous.

Insufficient

cooling.