SsangYong Rexton. Manual - part 418

SSANGYONG Y200

1F1-90 M162 ENGINE CONTROLS

KAA1F190

KAA1F180

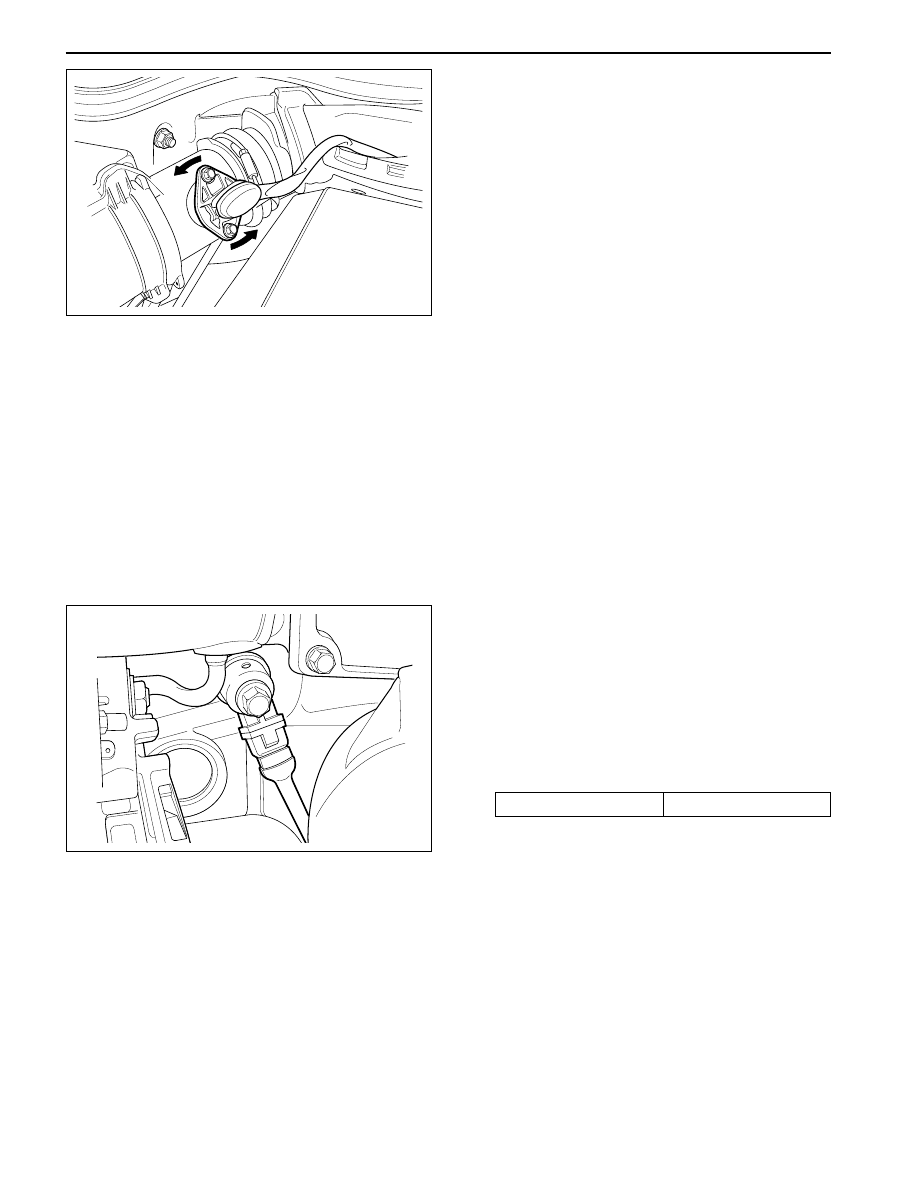

KNOCK SENSOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the knock sensor electrical connector

from the intake manifold bracket.

3. Remove the knock sensor mounting bolt from the

knock sensor installed on the cylinder block.

Installation Notice

HOT FILM AIR MASS (HFM)

SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the Hot Film Air Mass (HFM) sensor

electrical connector.

3. Remove the HFM sensor retaining screws.

4. Turn the HFM sensor coupling in the direction

shown in the figure in the left so that it gets

separated from the contact surface.

Notice: Make sure the HFM sensor coupling

connects completely with the contact surface

installation.

5. Remove the HFM sensor.

6. Installation should follow the removal procedure

in the reverse order.

Tightening Torque

25 N•m (18 lb-ft)

4. Remove the knock sensor.

5. Installation should follow the removal procedure

in the reverse order.